Indoor vacuum electro-osmosis combined solidification tester

A technology of consolidation test and indoor vacuum, applied in the direction of instruments, scientific instruments, soil material testing, etc., can solve the problem of inability to accurately grasp the stress and deformation of soil samples, the inability to accurately obtain design calculation parameters, and insufficient thorough research on design problems, etc. problems, to achieve the effect of reliable monitoring means, reliable data and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

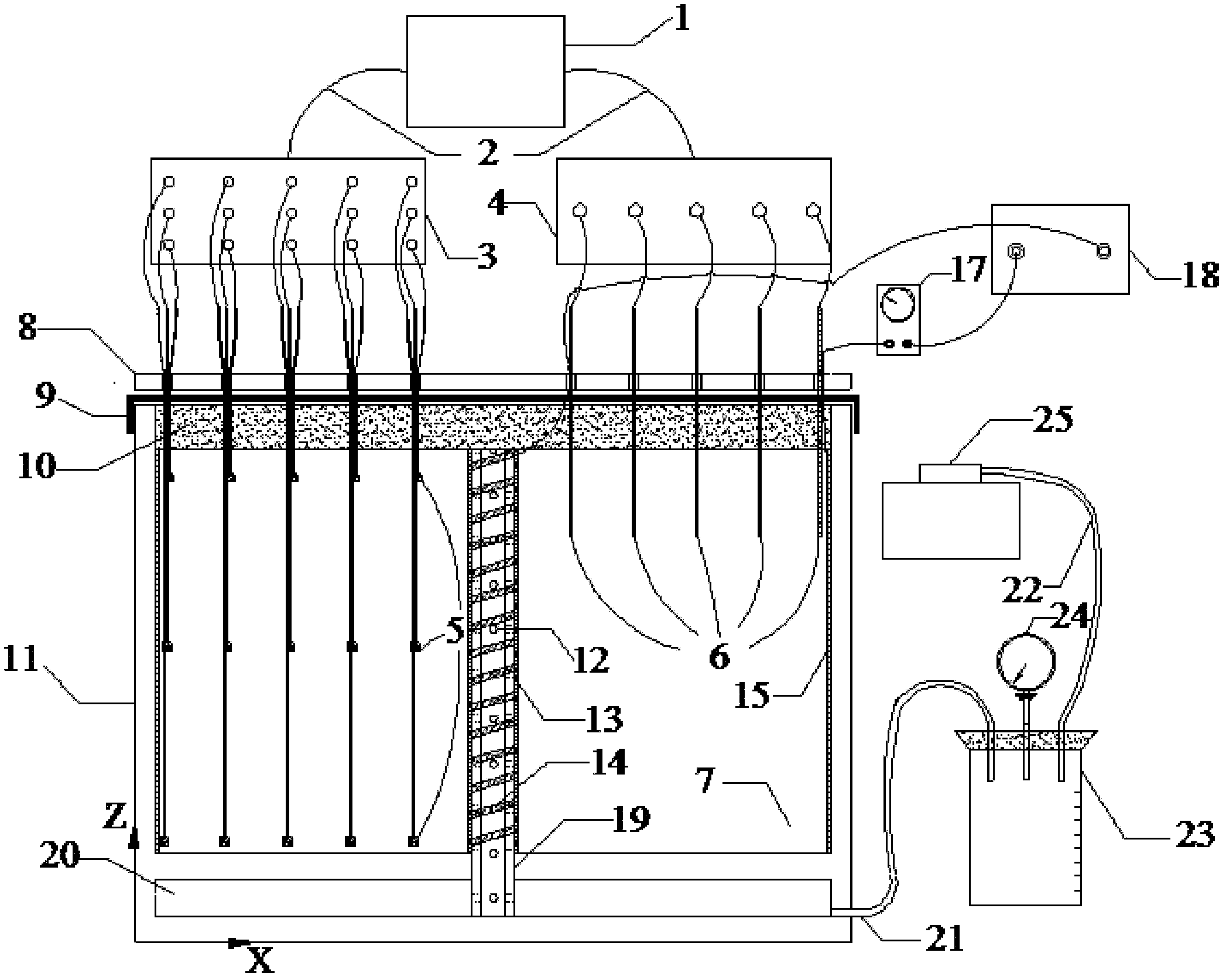

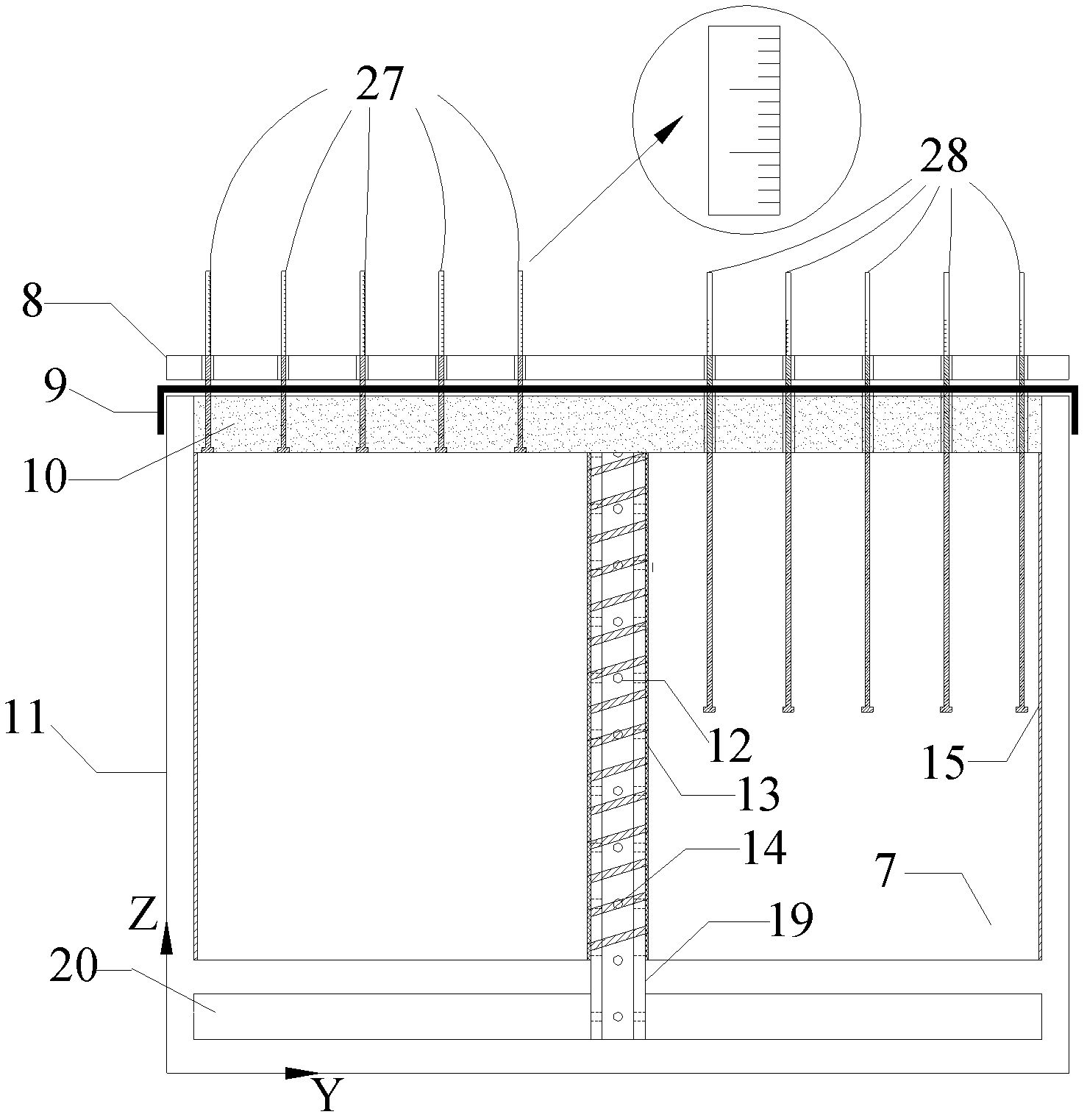

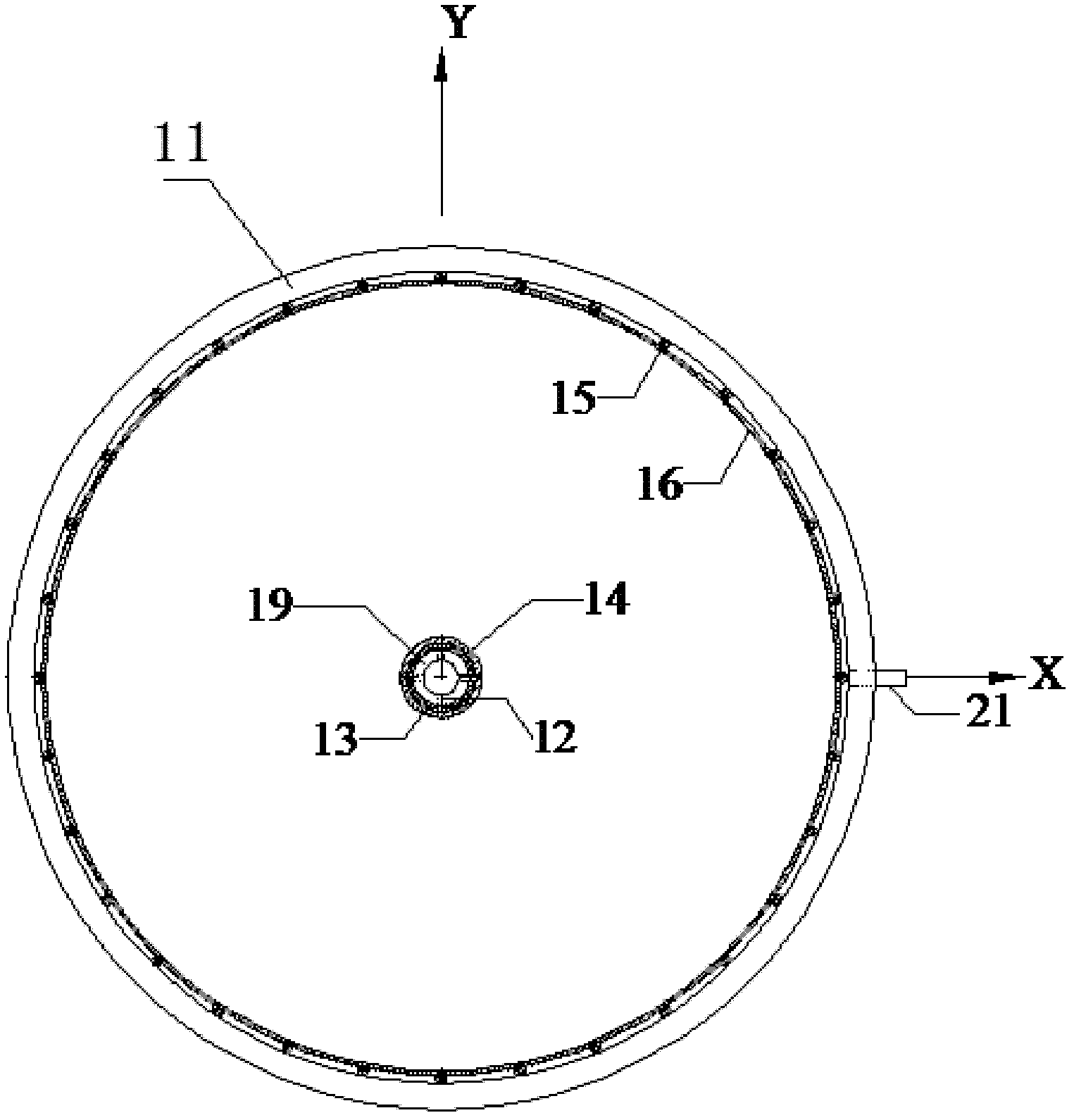

[0028] refer to figure 1 , image 3 , an indoor vacuum electroosmosis combined consolidation tester, comprising a main cylinder whose upper layer is a soil sample layer 11 and the lower layer is an aquifer 20, 32 vertical anode wires 15 are arranged around the main cylinder, and are the same as the inner diameter of the main cylinder And the electrode rings 16 at the upper, middle and lower positions of the main cylinder are connected, the soil sample layer 11 of the main cylinder and the aquifer 20 are connected through the vertical drainage pipe 19, and the vertical drainage pipe 19 is wrapped with a layer of geotextile 13, To prevent the soil sample from entering the drainage pipe, the geotextile 13 is wrapped with a cathode iron wire 14, and the cathode and anode iron wire, the ammeter 17 and the power supply 18 are connected in series to form a circuit, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com