Chair vertical impact test device and test method

A test device and seat technology, which is applied in the direction of using repetitive force/pulse force to test the strength of materials, etc., can solve the problems of inconsistent test methods, failure to reach unity, and no such seat vertical impact test device yet. , to achieve the effect of simple and fast test method, improved safety factor and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core of the present invention is to vertically impact the seat to be tested with the impact component suspended at a preset height by free falling, thereby completing the impact resistance test in the vertical direction of the seat.

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

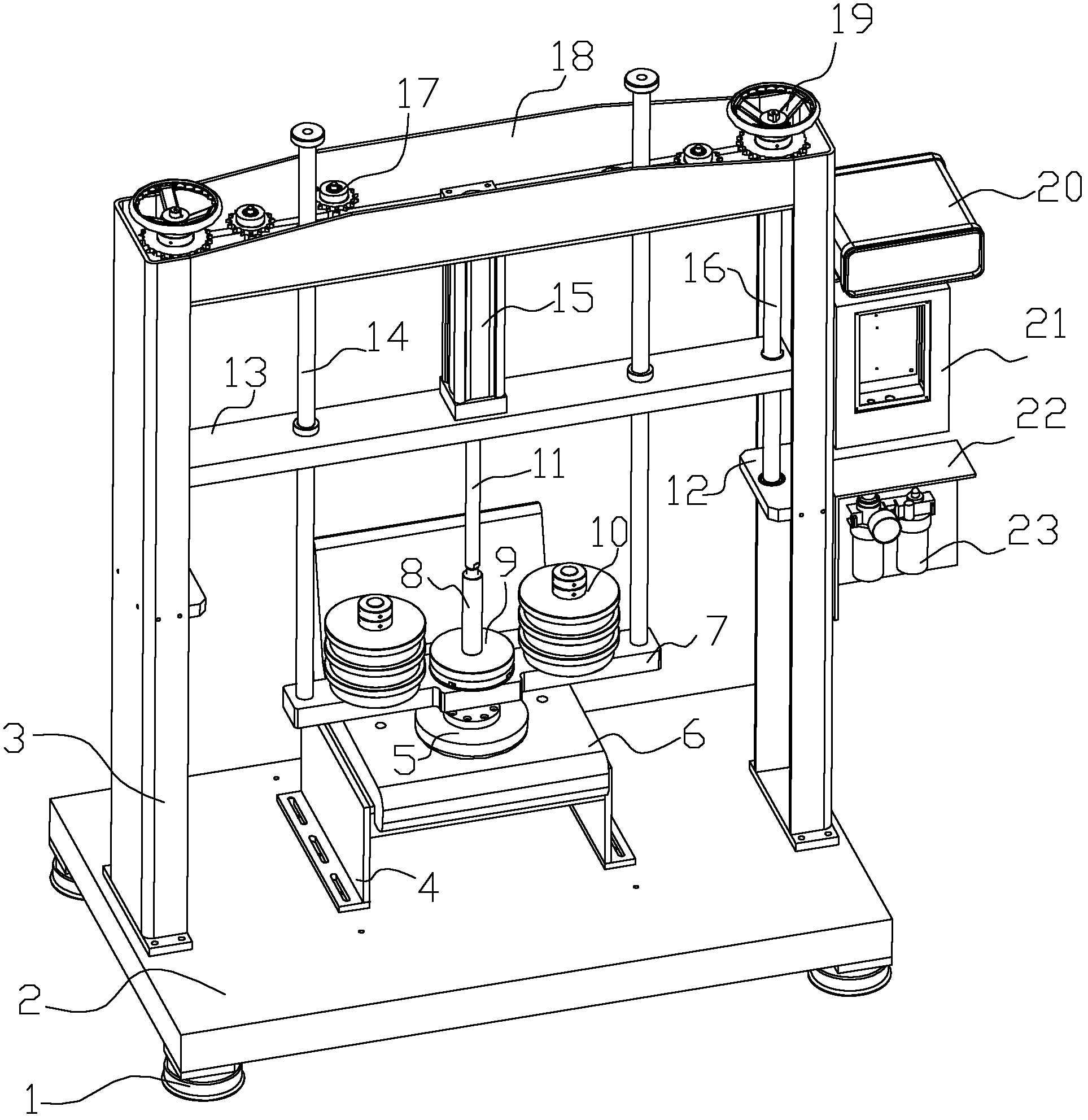

[0021] see figure 1 , represents a preferred embodiment of the seat vertical impact test device of the present invention. The vertical impact test device comprises a test stand, a mounting bracket, a bumper and a lifting mechanism, wherein: the test bench carries a test seat 6; the left and right columns 3 of the mounting bracket are fixed on the test bench; the bumper is in the first state by The lifting mechanism lifts to the preset suspension height of the mounting bracket cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com