Penetrating-stretching type pore water pressure measurement device and measurement method thereof

A pore water pressure and measuring device technology, which is applied in the direction of fluid pressure measurement using liquid as a pressure-sensitive medium, can solve the problems of difficulty in ensuring the installation requirements of piezometric tubes, large variability, etc., and achieve simple and easy implementation and operation of the measurement method Convenience and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

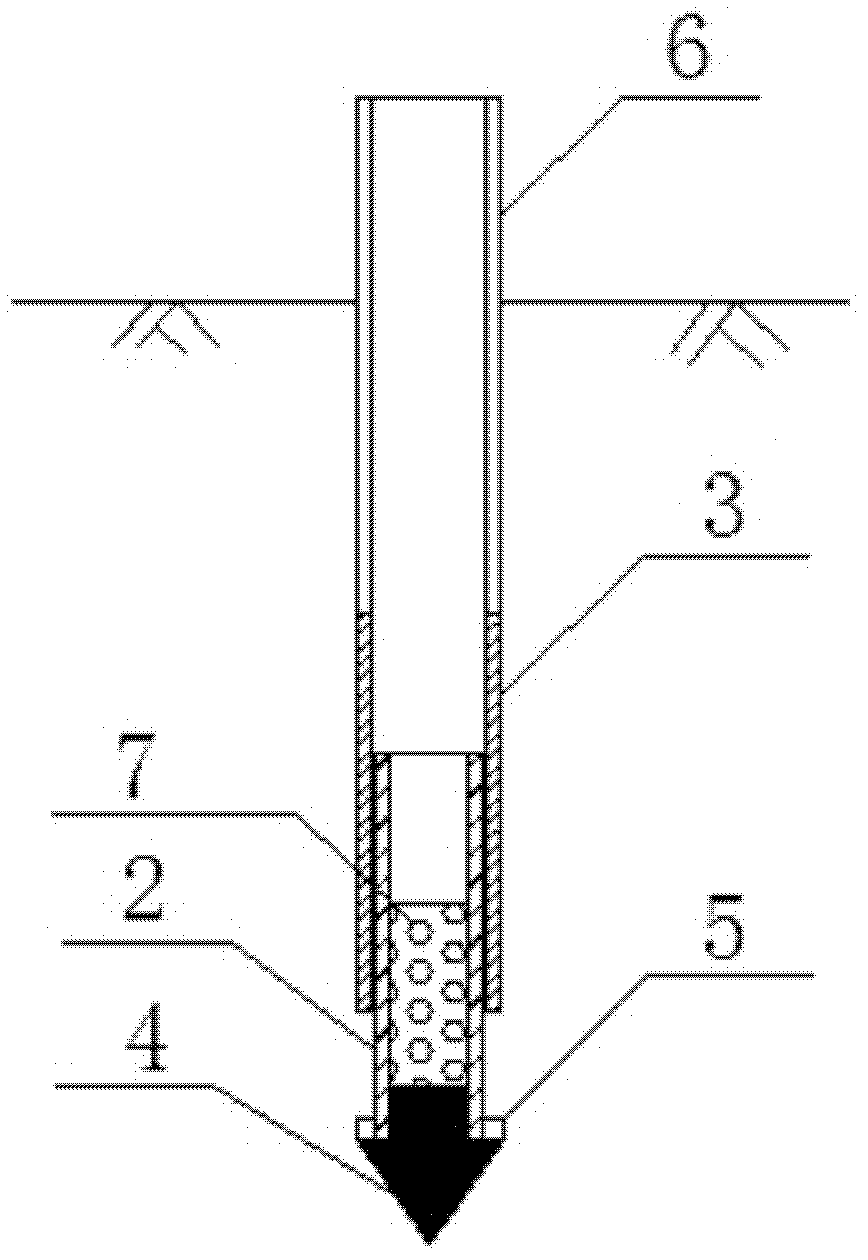

[0041] In a construction site in Jilin, the conical penetrating head 4 is first connected with the water filter pipe 2 through pins. The water filter pipe 2 is a PVC pipe, and the filter paper is wrapped around the water filter pipe 2. The pipe 3 is tightly pressed on the shoulder of the tapered penetrating head 4 through the gasket 5, the water filter pipe 2 is slidingly matched with the sleeve pipe 3, the bottom end of the pipe 6 is nested on the sleeve pipe 3, and the diameter of the water filter pipe 2 is 2.0 cm, the diameter of the water seepage hole 7 on the filter pipe 2 is 1 mm, and the distance between the water seepage holes 7 is 2 cm,

[0042] The measurement method of the penetration-extension pore water pressure measuring device comprises the following sequence and steps:

[0043] a. Before the test, the pore water pressure probe 1 and the upper connected conduit 6 are driven into the design depth of the test soil layer by static penetration equipment or impactor;...

Embodiment 2

[0059] At a construction site where a foundation pit was excavated in Tianjin, the conical penetrating head 4 is first connected to the water filter pipe 2 through threads or pins, and the bottom end of the conduit 6 is threaded or nested on the casing 3, and the water filter pipe 2 is equipped with a sleeve The pipe 3, the water filter pipe 2 and the sleeve pipe 3 are slidingly matched, and the sleeve pipe 3 is tightly pressed on the shoulder of the tapered penetrating head 4 through the gasket 5.

[0060] The water filter pipe 2 is provided with water seepage holes 7, and the water seepage holes 7 are equally spaced or irregularly distributed on the water filter pipe 2. The diameter of the water seepage holes 7 is 1.5mm, and the distance between the water seepage holes 7 is 3cm. The diameter of the water filter pipe 2 is 2.0cm. The water pipe 2 is wrapped with filter paper, and the water filter pipe 2 is a PVC pipe, a polyester pipe or a metal pipe.

[0061] The measurement ...

Embodiment 3

[0078] In a reservoir in Tibet, the conical penetrating head 4 is first connected to the filter pipe 2 through threads or pins, the bottom end of the conduit 6 is threaded or nested on the casing 3, the casing 3 is installed outside the filter pipe 2, and the filter pipe 2 Slidingly matched with the casing 3, the casing 3 is tightly pressed on the shoulder of the tapered penetrating head 4 through the washer 5.

[0079] The water filter pipe 2 is provided with seepage holes 7, and the water seepage holes 7 are equally spaced or irregularly distributed on the water filter pipe 2. The diameter of the water seepage holes 7 is 2 mm, and the distance between the water seepage holes 7 is 5 cm. The diameter of the water filter pipe 2 is 2.0 cm. 2 are wrapped with filter paper outside, and the water filter pipe 2 is an iron pipe.

[0080] The measurement method of the penetration-extension pore water pressure measuring device comprises the following sequence and steps:

[0081] a. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com