Device used for drying materials by aid of low-pressure superheated steam

A superheated steam and drying device technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of limited internal space of rotary dryer, arranging a large number of heat exchange tubes, drying efficiency and drying degree of dryer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

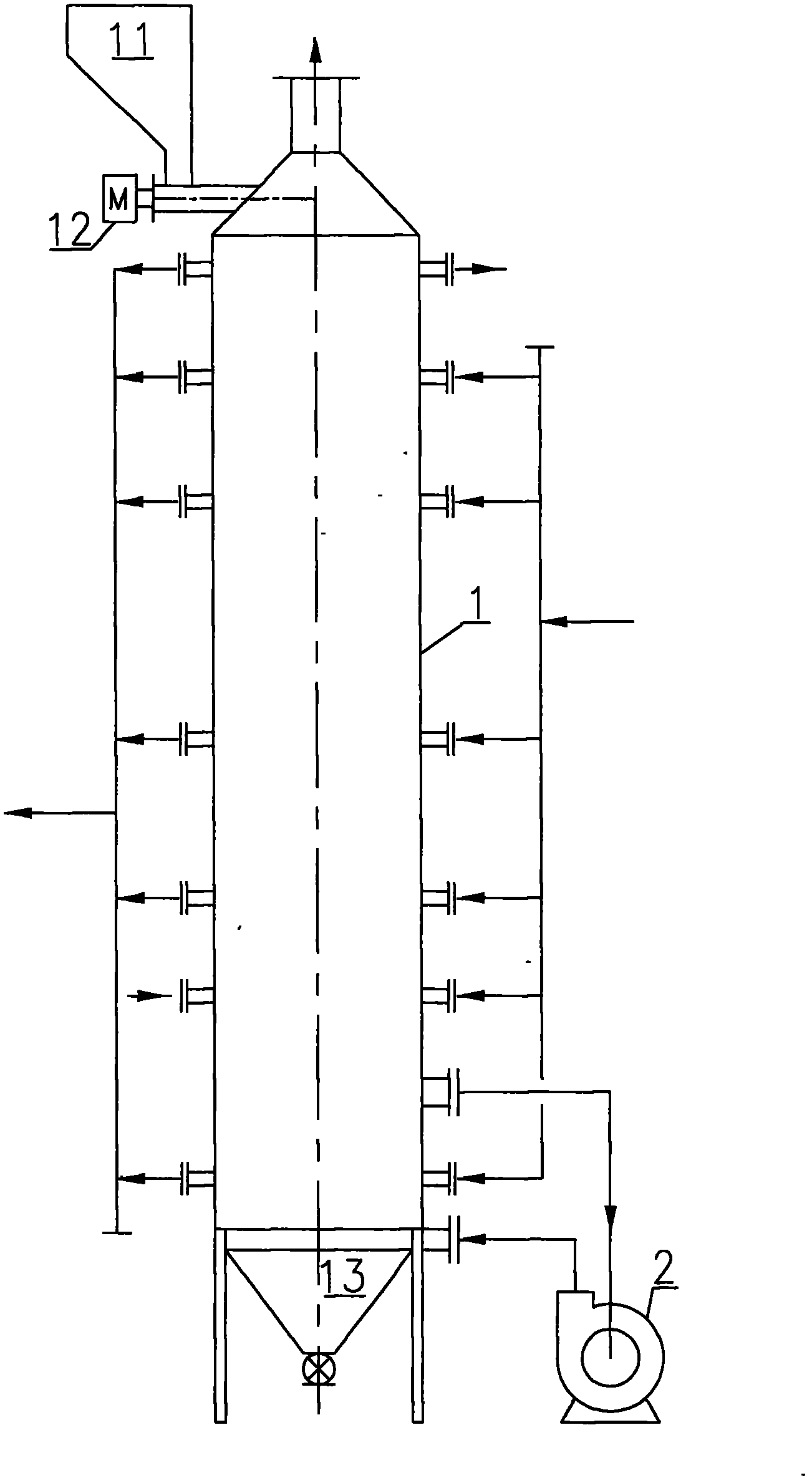

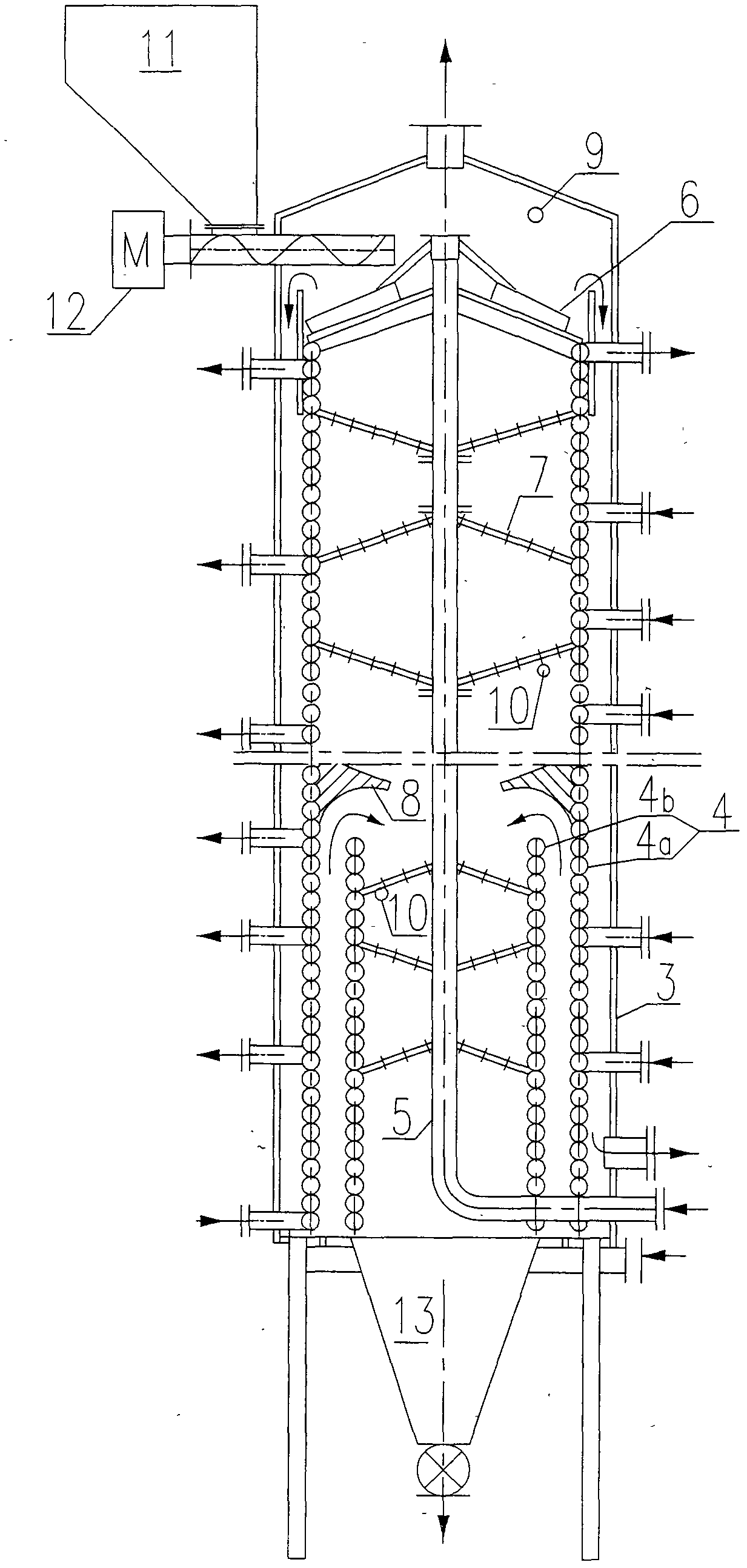

[0043] The technological process and specific implementation of the low-pressure superheated steam drying device involved in the present invention are:

[0044] When the drying device starts to work, the heat transfer oil heating system supplies high temperature heat transfer oil to the low pressure superheated steam drying device, and preheats the heat transfer oil heater 1 as the heat source of the drying device. A small amount of preheated wet material is sent down from the top hopper 11 of the heat transfer oil heater 1 into the preheated heat transfer oil heater 1, and the temperature of the material is raised until the external water evaporates, and the steam generated is first used To replace the air in the heat transfer oil heater 1, and then continue to be heated to the low-pressure superheated steam, when the steam is overheated and reaches 110°C, turn on the superheated steam booster fan 2, so that the low-pressure superheated steam inside the heat transfer oil heate...

Embodiment 1

[0057] The material to be dried is zirconium-titanium mixed ore or quartz sand with a moisture content of 20%, and its particle size is not greater than 3mm. It is required that the moisture content of the material after drying is less than 3%.

[0058] The characteristics of the material to be dried are: the drying of the ore is mainly to remove its external moisture, and the chemical properties of the ore are stable, and it is not sensitive to the working temperature of the drying medium, but the cleanliness and moisture content of the dried ore are strictly required, so It is necessary to use non-polluting drying medium in the drying device and increase the temperature of the drying medium in the decelerating evaporation section. According to the above conditions, the low-pressure superheated steam drying technology is used, and a set of low-pressure superheated steam drying device related to the present invention is used for drying treatment.

[0059] The technological con...

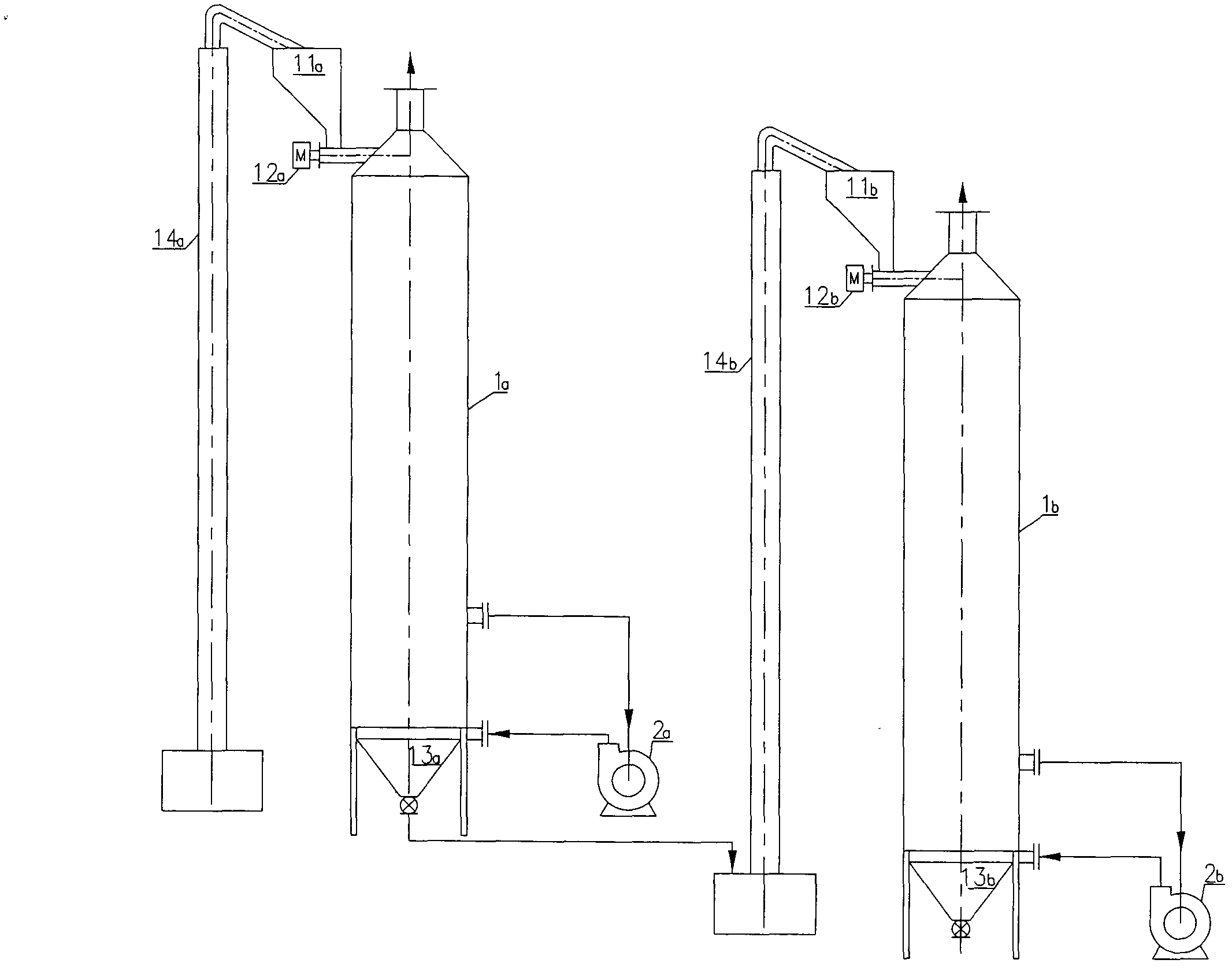

Embodiment 2

[0070] The material to be dried is corn or wheat or rice with a moisture content of 13%, and the moisture content of the material after drying is required to be less than 5%, and the processing capacity of a single drying device is 200 tons / day.

[0071] The characteristics of the dried material are: the drying of the non-breeding grain is mainly to remove its external moisture and part of the internal moisture. Although the chemical properties of the grain are stable, the high working temperature of the drying medium will affect the quality of the dried grain. Therefore, it is necessary to limit the drying medium temperature and heating conditions during the drying process of grain materials. In addition, due to the limited conditions of the grain drying treatment site, it is impossible to properly preheat the dried grain. For this reason, it is necessary to increase the flow rate of the drying medium in the constant-speed evaporating section and reduce the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com