LED (light-emitting diode) lamp and manufacturing method thereof

A technology of LED lamps and manufacturing methods, which are applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve problems such as poor heat dissipation of LED lamps, and achieve good electrical insulation performance, reduced heat dissipation paths, and excellent heat dissipation effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

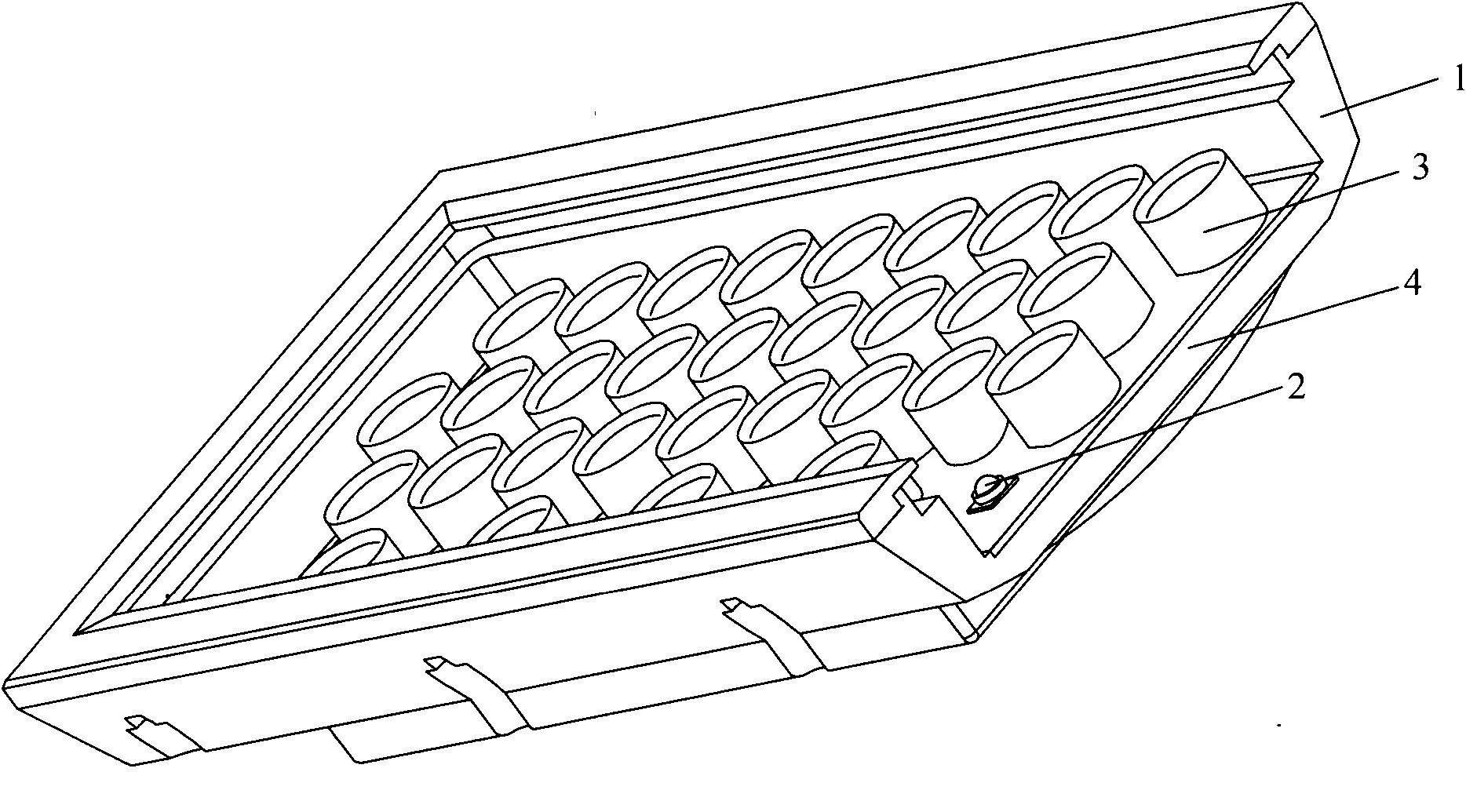

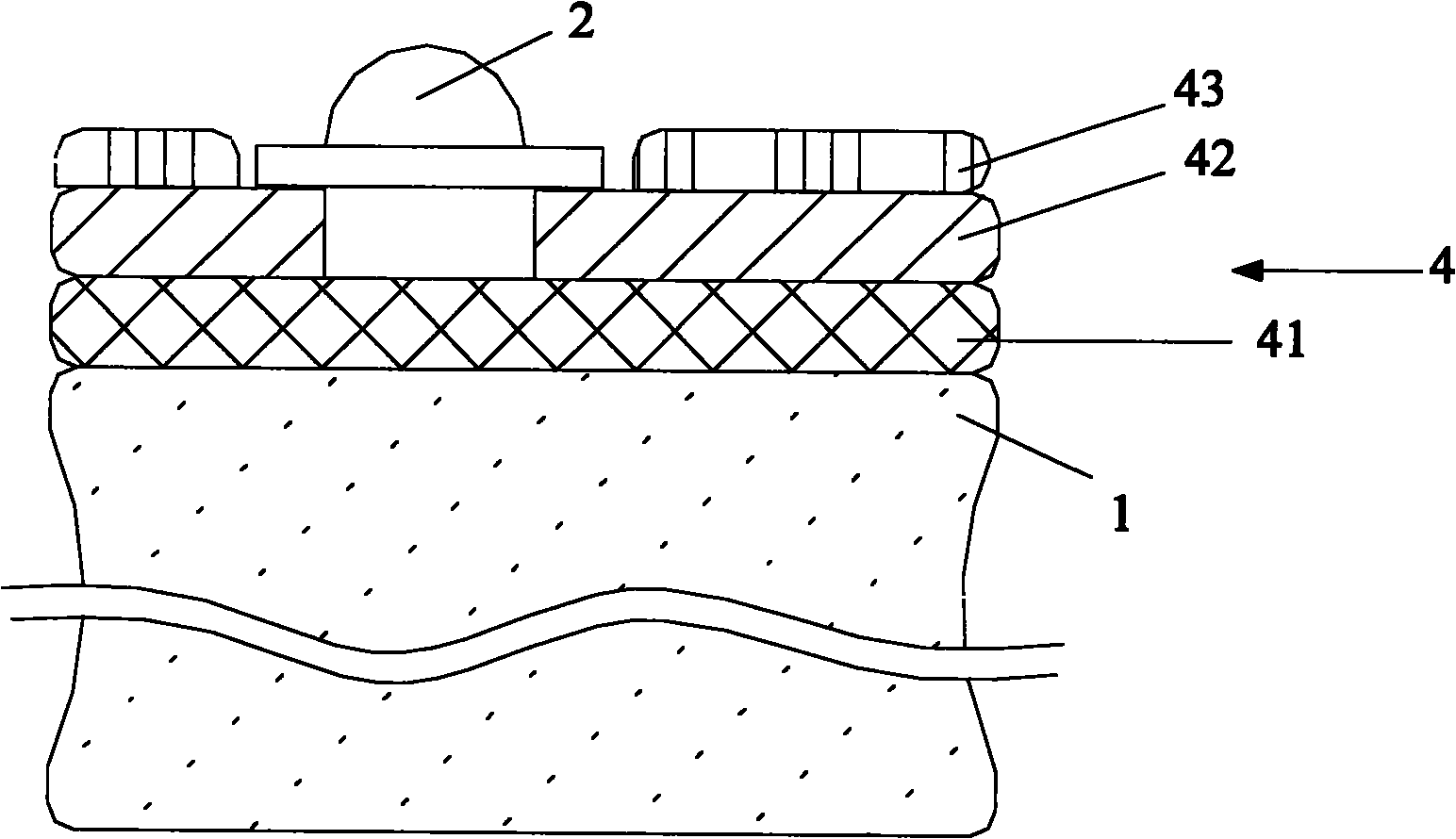

[0048] refer to figure 2 and image 3 , The LED lamp includes a mounting lamp housing 1, an LED 2, and a mounting composite layer 4. The mounting composite layer 4 includes a base insulating layer 41 and a conductive circuit layer 42 in sequence from bottom to top. The chip 21 of the LED2 is mounted on the mounting surface of the conductive circuit layer.

[0049] The insulating base layer 41 plays an insulating role and prevents the circuit short circuit from being in direct contact between the conductive circuit layer 42 and the mounting lamp housing 1 .

[0050] The conductive circuit layer 42 is provided with a mounting surface and a non-mounting surface, and is used for arranging the chips 21 connected to the LED 2 , which helps to ensure stable circuit contact and orderly arrangement.

[0051] Further, an insulating layer 43 is laid on the non-mounting surface of the conductive circuit layer 42 . The insulating layer 43 is located around the LED 2, which can prevent...

Embodiment 2

[0056] This embodiment is basically the same as the first embodiment, the difference being that: a silk screen layer 44 is laid on the insulating layer 43 . The silk screen layer 44 can be used for printing information identifying LED lamps, and serves as a protective insulating layer to further ensure insulating performance. Wherein, the process of silk screen printing is a prior art in this field, and will not be repeated here.

[0057] To sum up, the present invention can reduce the thermal resistance to the minimum by directly mounting the LED on the mounted lamp housing, and effectively export the internal heat, thereby achieving an excellent heat dissipation effect.

[0058] In addition, the present invention also provides a method for manufacturing an LED lamp, which includes the following steps:

[0059] Step 100, perform pretreatment of blanking, pickling, cleaning and drying on the mounted lamp housing.

[0060] Step 101, laying a mounting composite layer on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com