Energy-saving micro-resistance adjustable self-balancing check valve

A check valve, adjustable technology, applied in the direction of functional valve type, control valve, valve device, etc., can solve the problems of energy consumption and pressure drop, low energy consumption, small pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

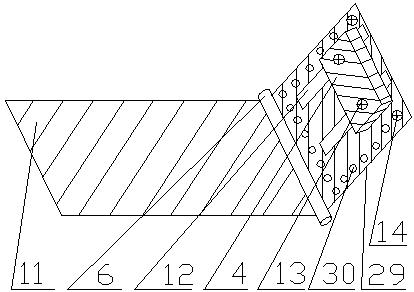

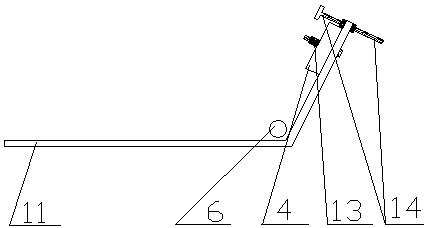

[0039] exist figure 1 In the embodiment of the horizontally installed check valve shown in —10: an energy-saving micro-resistance adjustable self-balancing check valve, including a valve cavity 3 and a valve core plate 11, one end of the valve core plate 11 is connected to a rotating shaft, and the rotating shaft Installed in the upper right corner of the valve cavity 3, a valve core plate balance plate 29 is connected to the valve core plate rotating shaft 6 ends, the valve core plate balance plate 29 forms an obtuse angle greater than 90° with the valve core plate 11, and the valve core plate balance plate The valve core plate 11 balance block 4 is installed on the 29 and forms the valve core plate 11 balance device with the valve core plate balance plate 29. The valve core plate 11 balance device has four types:

[0040] (a) Adjustable balance device, there are two strip-shaped balance device adjustment grooves 12 on the valve core plate balance plate 29, a balance weight 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com