Elasticity-adjustable gas pressure spring

A gas spring and adjustable technology, applied in the field of spring manufacturing, can solve the problems of complex structure, insufficient deformation stroke of the gas spring, and high requirements for parts matching, achieve good horizontal and vertical ventilation, save transportation costs, and overcome the effects of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

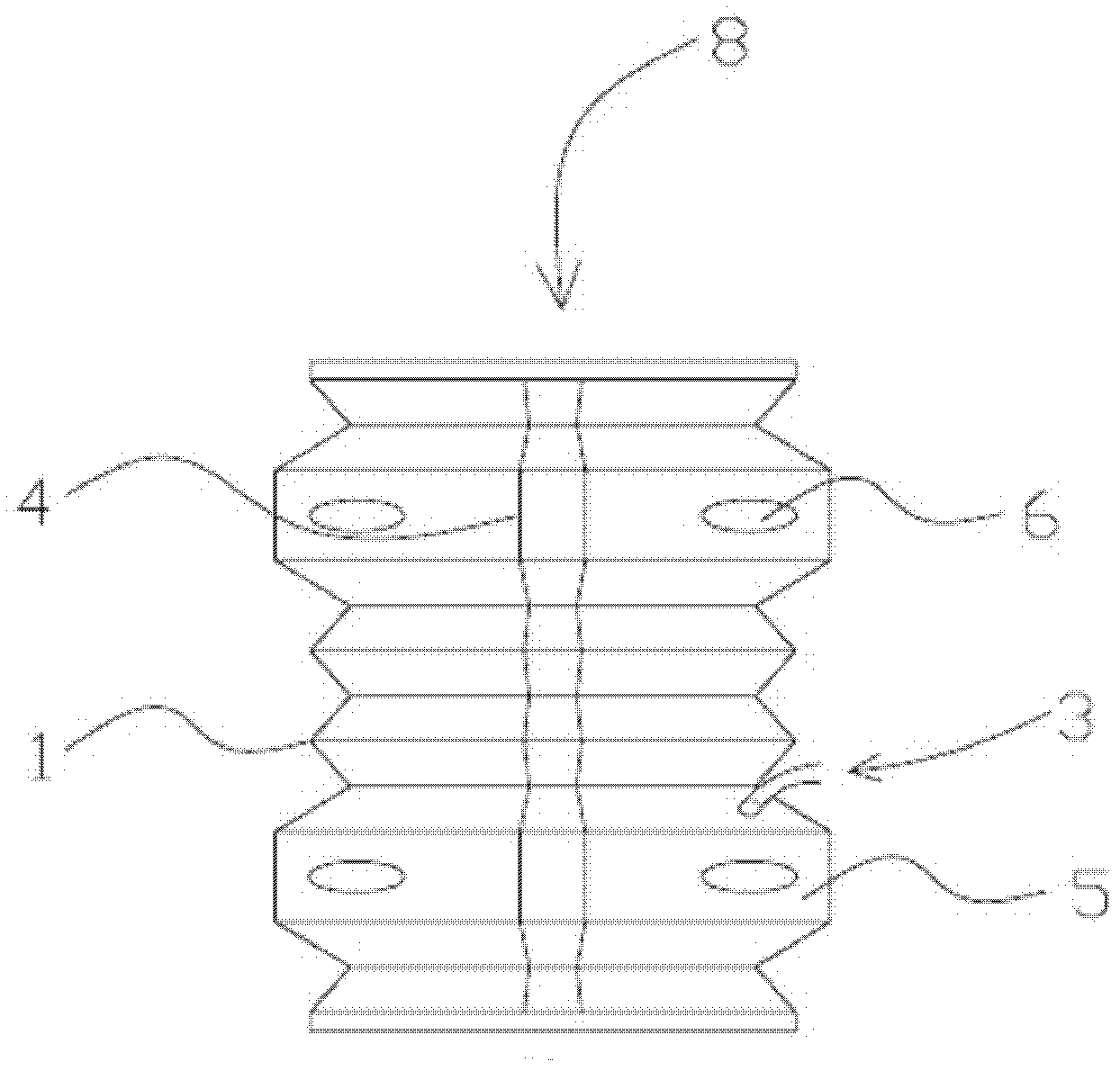

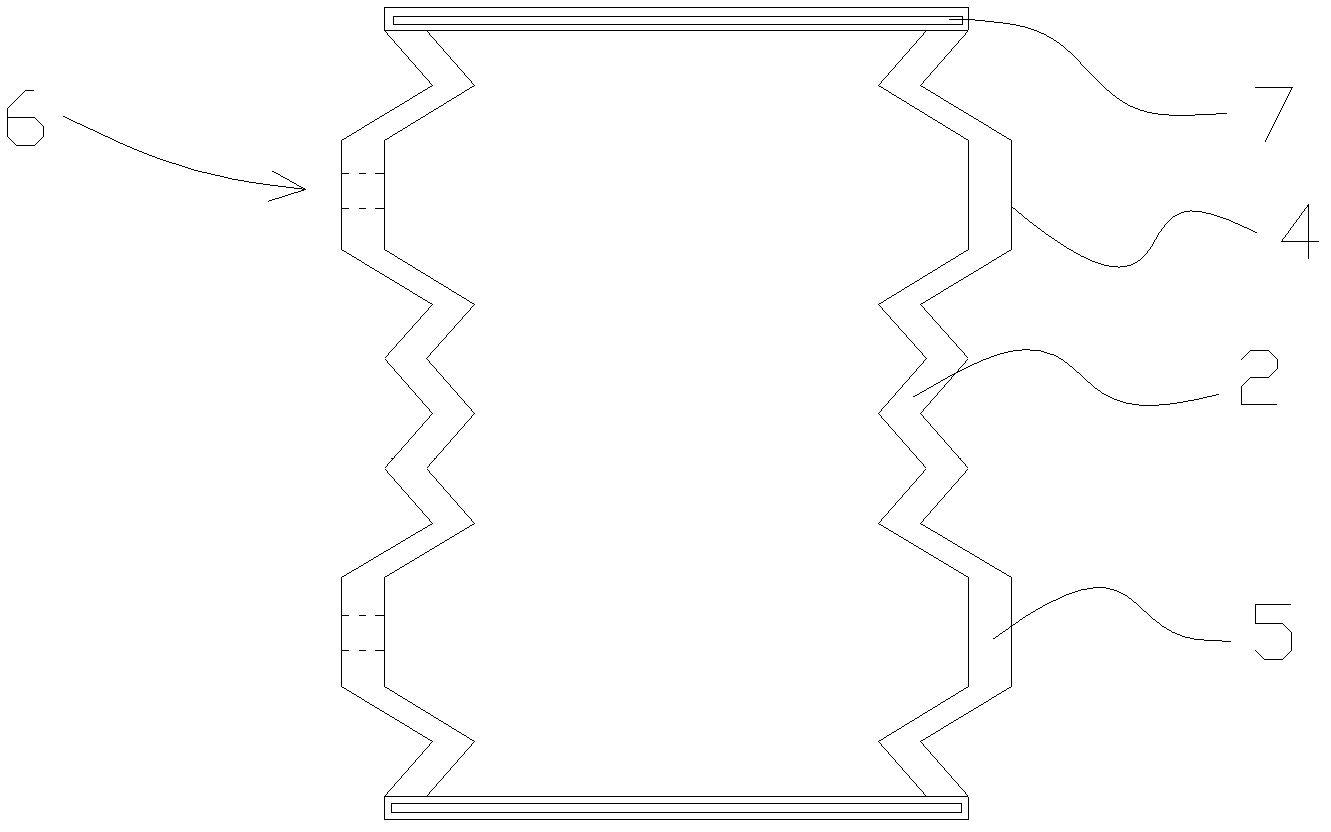

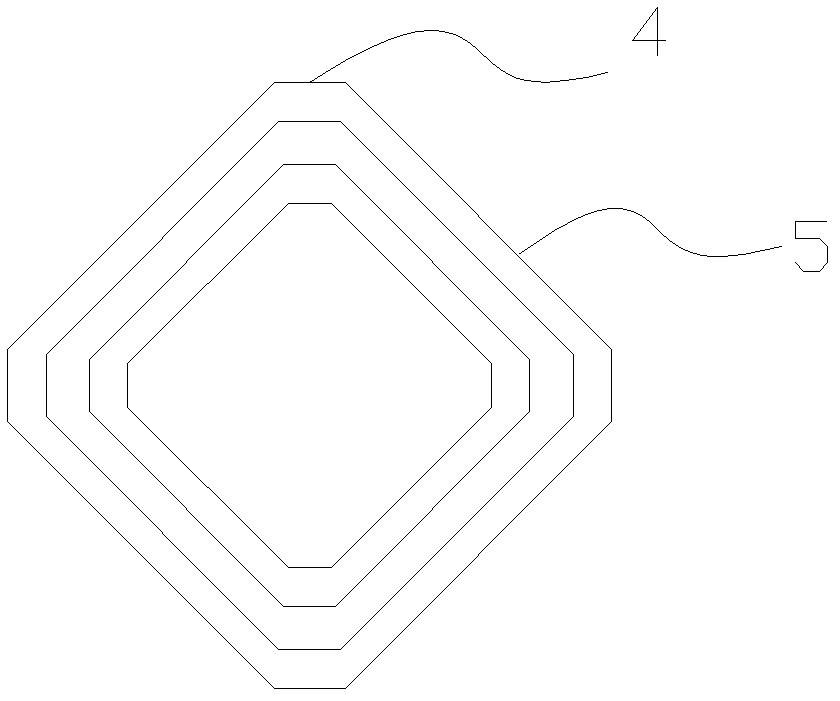

[0027] Such as Figure 1-Figure 3 As shown, the elastic force adjustable gas spring described in this embodiment includes a spring body, the spring body is formed by a hollow cavity column 1, and the cavity column 1 is a double-layer side wall structure. A closed chamber 2 containing pressure gas is formed between the double-layer side walls. The chamber column 1 is corrugated and has a vent hole 3 communicating with the chamber 2. The chamber column 1 has at least one layer of side walls Made of rubber, nylon, TPU or their composite materials with fabric, the rubber, nylon and / or TPU are filled in the pores of the fabric or attached to one side of the fabric. The upper and lower ends of the corrugated section in the middle of the cavity column 1 form two annular sections 5 with straight lines 4 that expand outward, and the outer ends of the two annular sections 5 have a cavity column mouth 8 with a reduced diameter. The linear surface 4 constitutes the connection surface, an...

Embodiment 2

[0031] Such as Figure 6-Figure 8 As shown, the cross-section of the chamber column 1 is circular, and the annular section 5 is also circular. There are two ventilation holes 3 and four ventilation holes 6 are evenly distributed on the annular section 5 in a cross shape.

[0032] In the technical solution of the present invention, the cross-section of the chamber column 1 can also be any polygon, and the thickness of the chamber 2 can be determined according to requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com