Barrel-shaped integral concrete water storage tower tank and preparation method thereof

A concrete and water storage tower technology, which is applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of inability to carry and move, short service life, high use cost, etc., and achieve superior performance, easy handling and hoisting, The effect of scientific manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

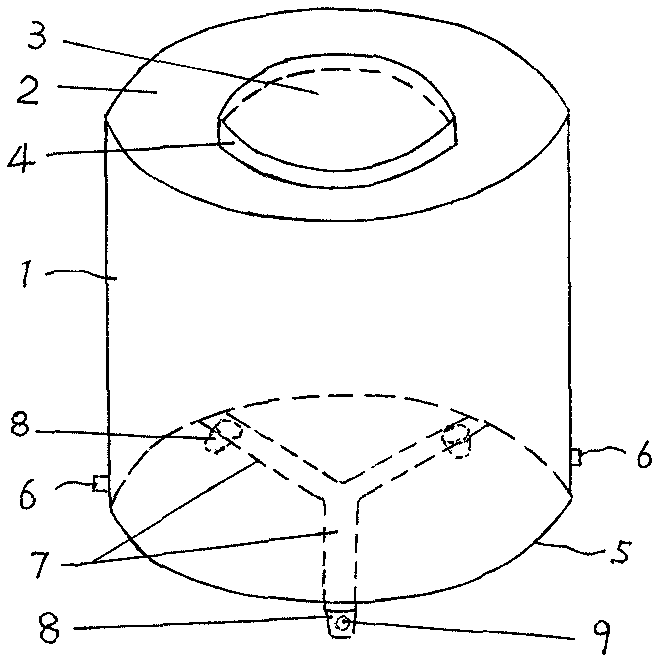

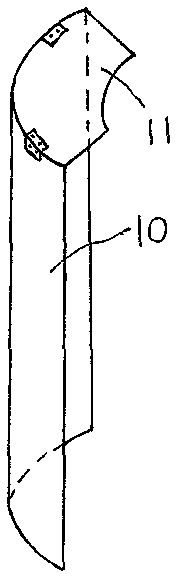

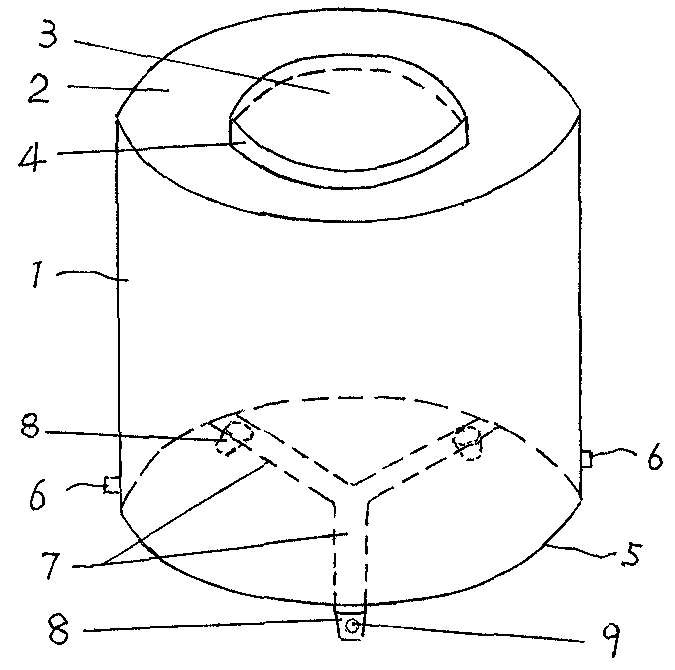

[0027] With reference to the accompanying drawings, the specific parts of the barrel-shaped integral concrete water storage tower tank of the present invention include: 1 ~ water storage tower tank body (containing body), 2 ~ tank top cover, 3 ~ water inlet (or feed port , diameter greater than 0.60 meters, can be used for installation and maintenance), 4 ~ cover (for water inlet or feed port cover, also known as the top cover), 5 ~ tank base, 6 ~ pre-installed at the bottom of the tank Retained holes (there are two reserved holes for water inlet, outlet or sewage outlet), 7~reinforcing ribs on the base of the tank, 8~supporting feet, 9~prepared holes penetrating through the supporting feet Leave installation holes (for supporting surface anchoring), 10~fan-shaped (inner) top molds, 11~inside molds (ie arc or arc-shaped inner molds).

[0028] The structural feature of the present invention is that the 1 part of the tank body, the 2 parts of the tank top cover and the 5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com