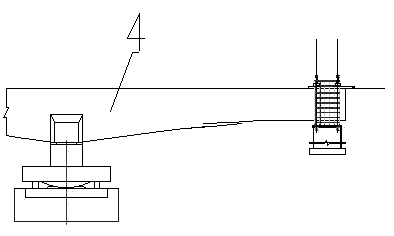

Construction technology of closure section for rotary continuous beam for overpass electrified railway and hanging basket thereof

A technology for electrified railways and construction technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increased construction period, high construction cost, long construction time of existing lines, etc., to save construction time and reduce construction risks. , the effect of shortening the in-position time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

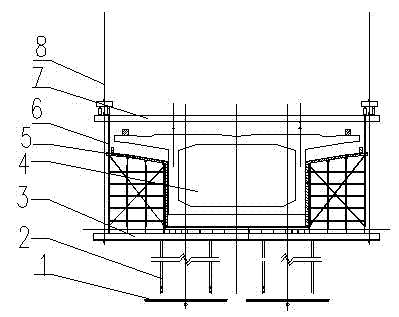

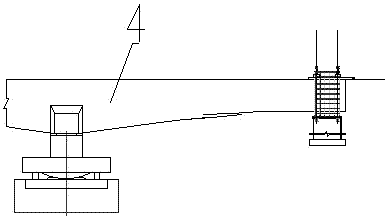

[0025] The technological method of this invention comprises the steps:

[0026] (1) Design the size of the hanger according to the section of the closing section, check the bearing capacity of the hanging blue, and choose different types of materials according to different bearing capacity requirements;

[0027] (2) Assemble the hanging blue at the selected position outside the existing line on one side of the T structure, and the hanging connection system of the hanging blue formwork adopts Φ25 finishing rebar;

[0028] (3) The bottom of the protective system under the formwork is fully covered with 5mm thick steel plates, and the double-sided mesh net is hung on the outside of the scaffold to ensure that the suspension of the dense mesh net is firm during construction;

[0029] (4) When pouring the closing section, the "skylight" point is required to block the power outage construction, and the binding steel bars are constructed in the formwork, and the "skylight" point is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com