High wall scaffold lifting moving trolley and construction method

A technology for moving trolleys and scaffolding, which is applied to the accessories of scaffolding, construction, and housing structure support, etc., can solve the problems of steel pipe scaffolding requiring a lot of materials, occupying a large area of construction area, affecting the passage of construction sites, etc., and saving labor for disassembly and assembly. cost, speed up the construction progress, and the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

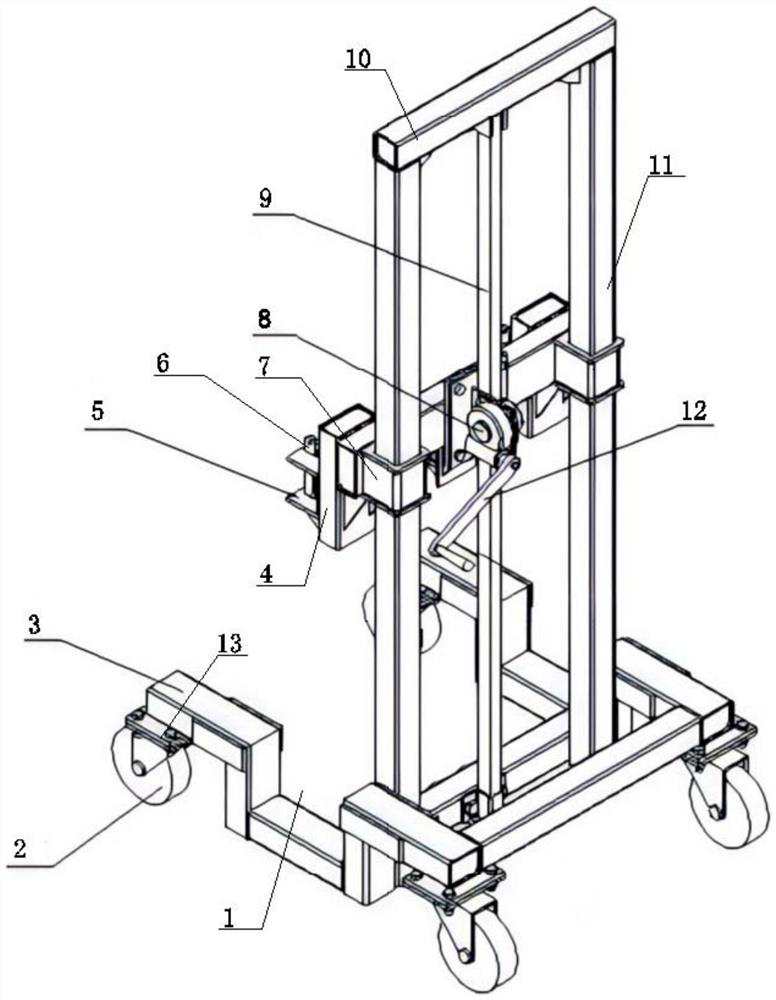

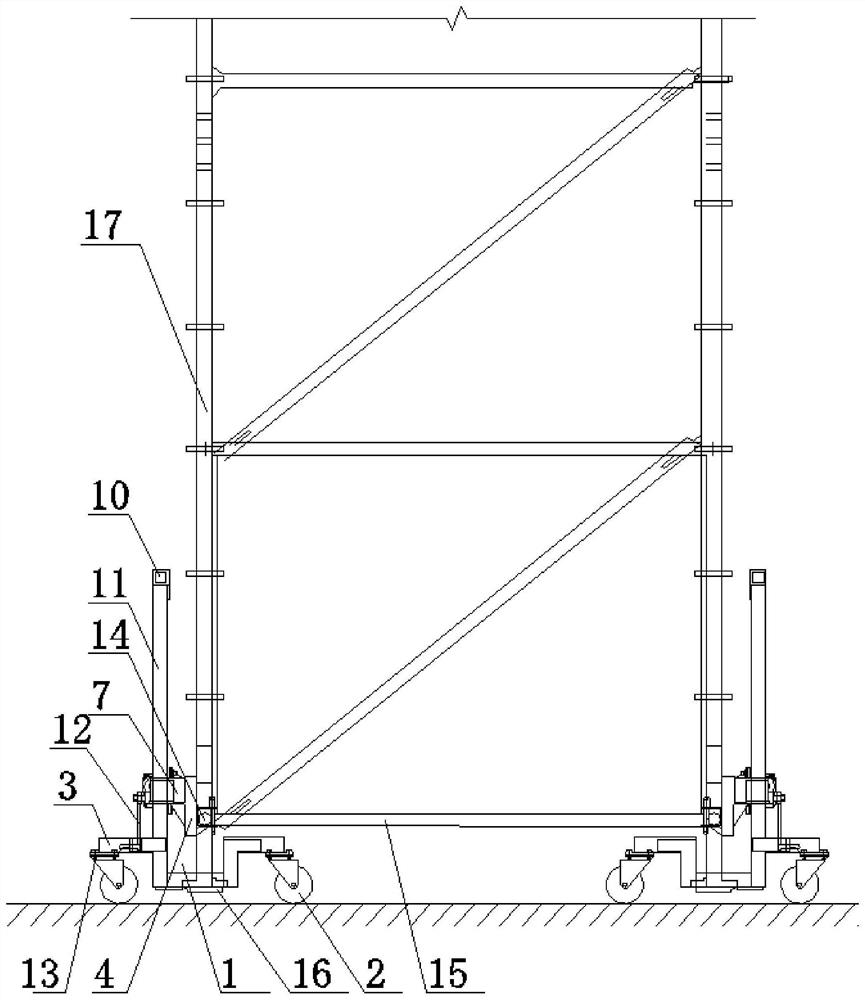

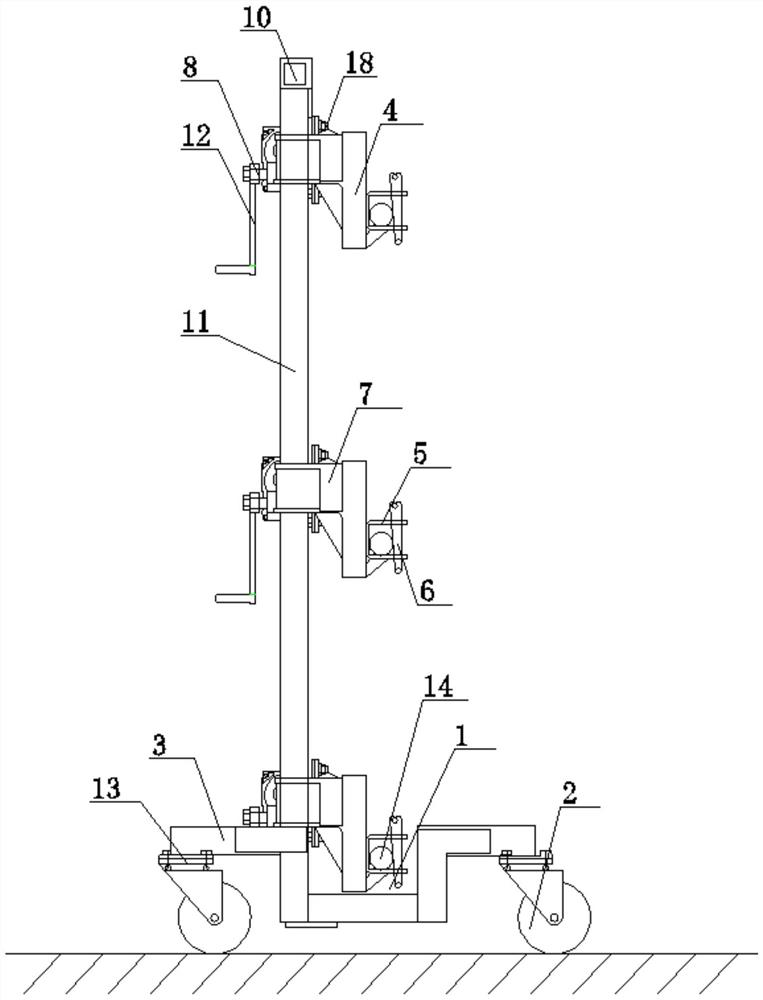

[0032] refer to Figure 1-7, The high-wall scaffolding lifting mobile trolley includes a frame 3, the lower end of the frame 3 is provided with a moving mechanism 2, the upper end of the frame 3 is provided with a pipe beam 10 above the gantry, and the pipe beam 10 above the gantry and the frame 3 are connected There are two symmetrically arranged gantry square tube columns 11, a rack 9 is arranged between the two gantry square tube columns 11, and the two ends of the rack 9 are respectively connected with the frame 3 and the pipe beam 10 above the gantry. Fixed connection, one side of the two gantry square tube columns 11 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com