Drum-type washing machine

A drum-type washing machine and drum technology are applied to other washing machines, washing machines with containers, control devices of washing machines, etc., and can solve the problems of increasing economic burden and unable to completely prevent dirt from re-adhering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] figure 1 It is a longitudinal sectional view of the front-loading-type washing machine in Embodiment 1 of this invention.

[0035] like figure 1 As shown, the front-loading washing machine of this embodiment includes at least a water tank 52 disposed in the washing machine main body 51 to be able to swing freely; a bottomed cylindrical rotating drum 53 disposed in the water tank 52 to be freely rotatable; and The motor 54 is installed on the outer side of the back surface of the water tank 52 , and the rotary drum 53 is rotationally driven by the motor 54 . At this time, for example, a concave drainage ditch 76 having a drainage port 71 is provided at the inner lower part of the side wall of the water tank 52 along the direction of the rotating shaft 63 of the rotary drum 53 .

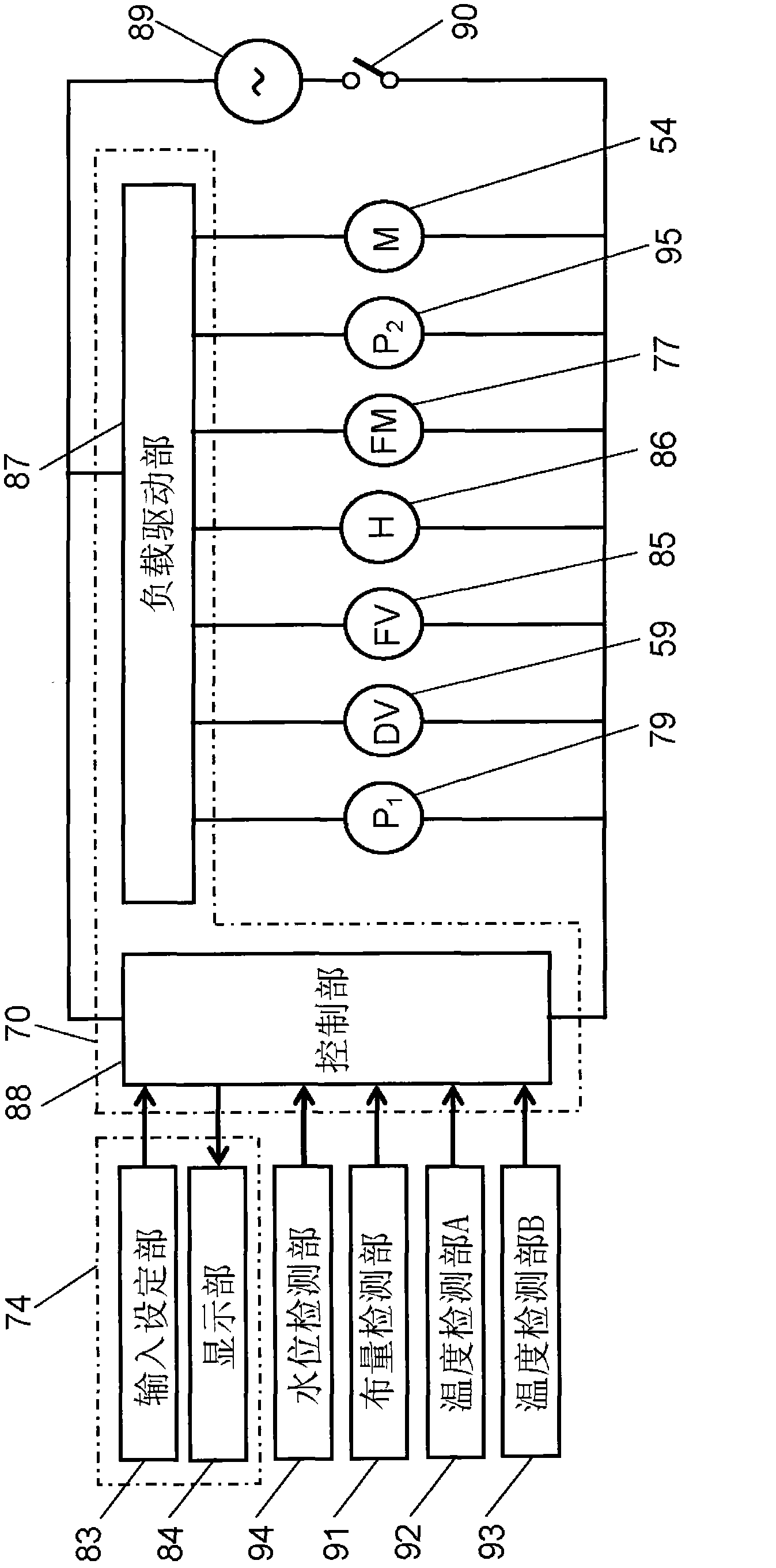

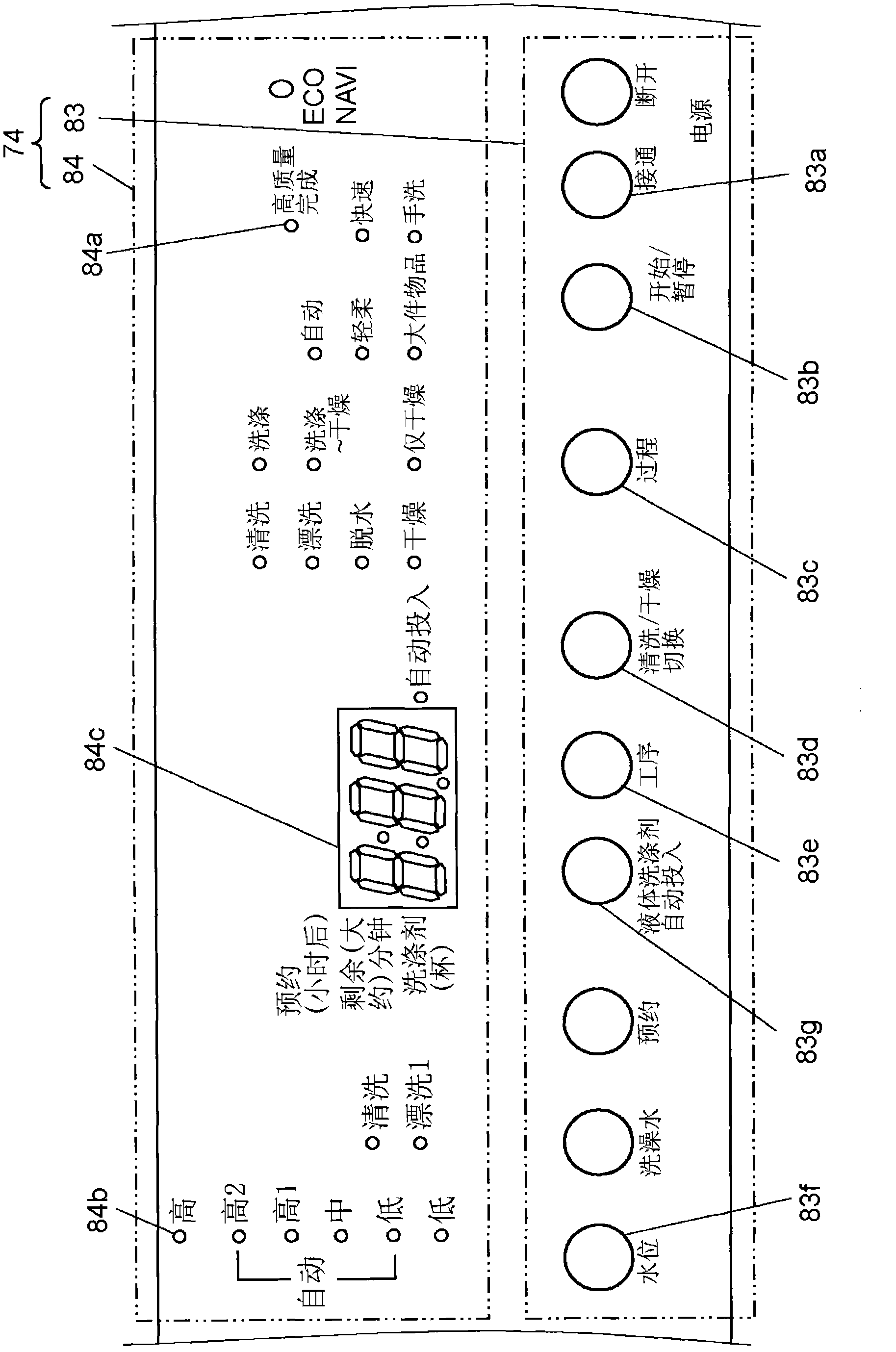

[0036] In addition, the front-loading-type washing machine of this embodiment has a function of using the control unit to figure 1 The motor 54 shown, the water supply system 55, the drain...

Embodiment approach 2

[0083] Next, a front-loading washing machine according to Embodiment 2 of the present invention will be described using drawings.

[0084] Figure 5A and Figure 5B It is a flowchart explaining the control from the washing process to the spin-drying process in the mode of high-quality finishing process of the front-loading-type washing machine according to Embodiment 2 of the present invention.

[0085] The difference between the front-loading washing machine of this embodiment and Embodiment 1 is that, in the high-quality finishing process mode from the washing process to the dehydration process, a dehydration process is provided after the water discharge in step S8 (step S101). Other controls, operations, and the like are the same as those in Embodiment 1, so explanations are sometimes omitted. Therefore, the dehydration process (step S101) is demonstrated in detail below, and since other processes are the same as Embodiment 1, it demonstrates briefly.

[0086] That is, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com