One-step preparation method of para aramid fibrids

A technology for para-aramid fibers and fibrids, which is applied in the field of one-step preparation of para-aramid fibrids, can solve problems such as equipment corrosion, complicated solvent recovery, and harsh operating environment, so as to avoid corrosion problems and achieve precise fibers. The effect of high size and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

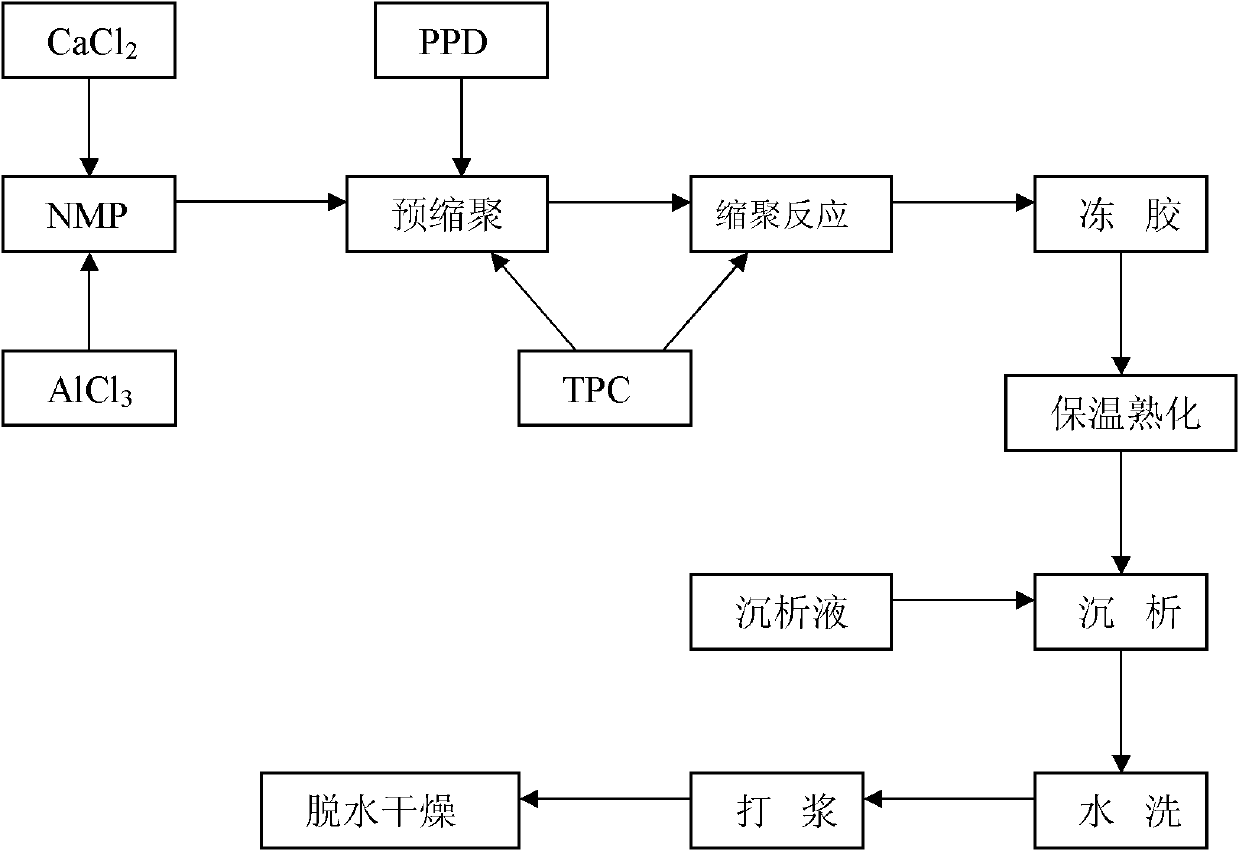

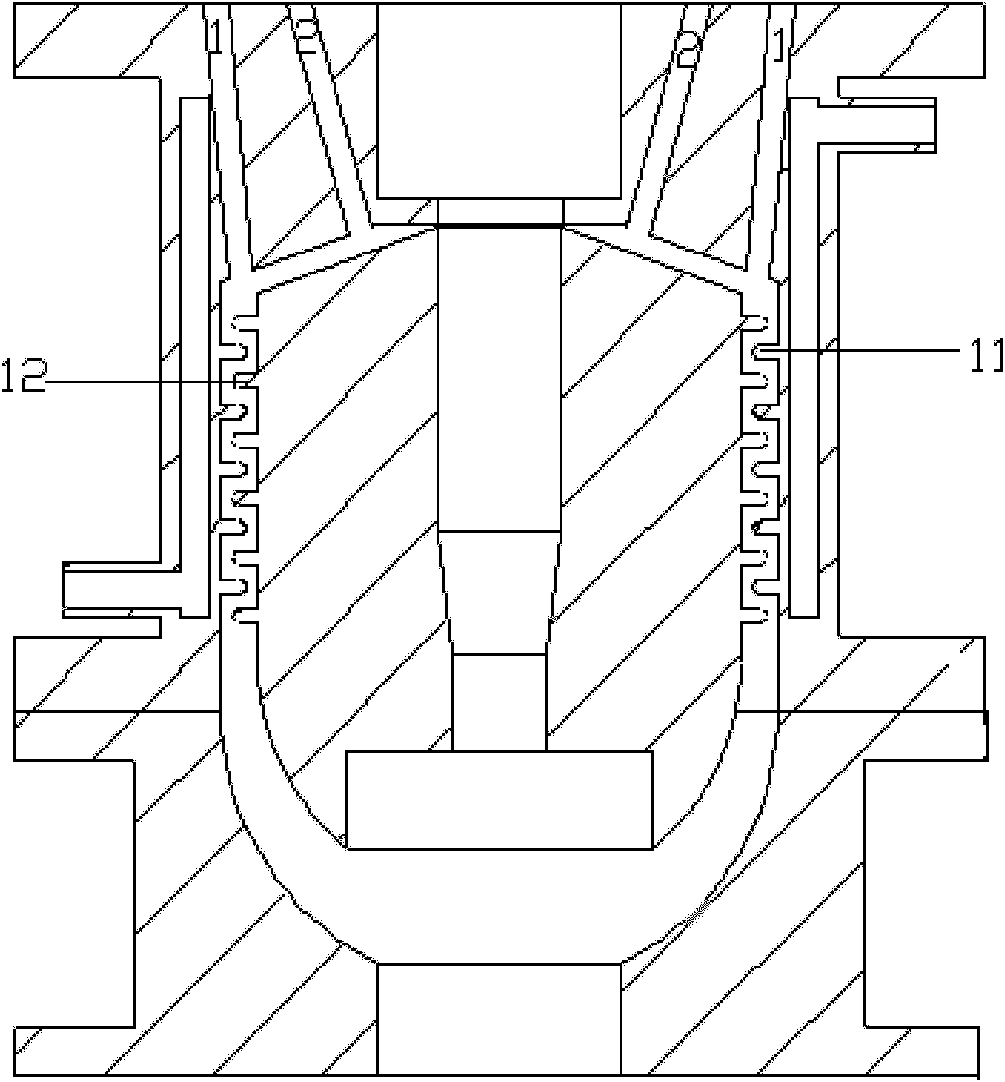

[0025] Such as Figure 1 Shown, respectively take 100L N-methylpyrrolidone (NMP), 3kg CaCl 2 and 2kg AlCl 3 , configured as NMP-CaCl 2 -AlCl 3 Polymerization solvent, under the protection of nitrogen, add 3.400kg of p-phenylenediamine to fully dissolve, add 3.840kg of terephthaloyl chloride at 5°C for pre-condensation reaction, add 2.560kg of terephthaloyl chloride for polycondensation reaction after the pre-condensation reaction, and react When colloid is produced in the process, the stirring is stopped, and the heat preservation and aging are carried out. The aging is carried out at 60° C. for 3 hours in a nitrogen atmosphere, and the intrinsic viscosity after aging is 42. The cured colloidal solution and the para-aramid pulp suspension (the average length of the para-aramid pulp is 0.5mm) with a mass percentage concentration of 0.05% pass through two colloid inlets 1 and two sedimentation liquids respectively The feed port 2 enters the precipitator for precipitation. Th...

Embodiment 2

[0027] Take 120LNMP and 3.5kg CaCl respectively 2 and 4.5kg AlCl 3 , configured as NMP-CaCl 2 -AlCl 3 Polymerization solvent, add 2.380kg of p-phenylenediamine under the protection of nitrogen to fully dissolve, add 2.682kg of terephthaloyl chloride at 5°C for precondensation reaction, add 1.788kg of terephthaloyl chloride after the precondensation reaction for polycondensation reaction, and react When colloid is produced in the process, the stirring is stopped, and the heat preservation and aging are carried out. The aging is carried out at 70° C. for 2 hours in a nitrogen atmosphere, and the intrinsic viscosity after aging is 7.9. The cured colloid solution and the mass percent concentration are 0.08% para-aramid pulp suspension (the average length of the para-aramid pulp is 0.8mm) through two colloid inlets 1 and two sedimentation liquids. The feed port 2 enters the precipitator for precipitating. The precipitator rotates at 2500rpm. The mass ratio of para-aramid colloid...

Embodiment 3

[0029] Take 100LNMP and 5kg CaCl respectively 2 and 2kgAlCl 3 , configured as NMP-CaCl 2 -AlCl 3 Polymerization solvent, add 2.160kg of p-phenylenediamine under the protection of nitrogen to fully dissolve, add 2.436kg of terephthaloyl chloride at 5°C for precondensation reaction, add 1.624kg of terephthaloyl chloride for polycondensation reaction after the precondensation reaction, and react When colloid is produced during the process, the stirring is stopped, and the heat preservation and curing are carried out. The curing is carried out at 80°C for 1.5 hours in a nitrogen atmosphere, and the intrinsic viscosity after curing is 6.5. The cured colloid solution and the mass percentage concentration are 0.02% para-aramid pulp suspension (the average length of para-aramid pulp is 0.6mm) through two colloid inlets 1 and two sedimentation liquids. Feed port 2 enters the precipitator for precipitator, the rotational speed of precipitator is 2500rpm, the mass ratio of para-aramid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com