Method for electrogalvanizing on surface of zinc alloy workpiece with blind holes

A workpiece surface, electro-galvanizing technology, applied in the field of electro-galvanizing, to achieve the effect of improving deep plating ability, complete coating and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

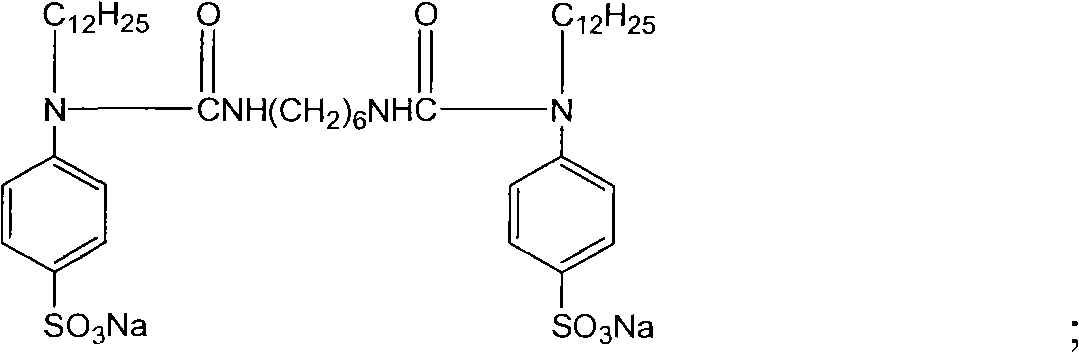

Image

Examples

Embodiment 1

[0033] Zinc alloy die-casting parts with different depths of blind holes were used as workpieces to be plated. The blind holes were circular holes with a diameter of 10 mm and depths of 30 mm, 40 mm, 50 mm and 60 mm, respectively.

[0034] The electroplating process is: degreasing, water washing, rust removal, water washing, electrogalvanizing, water washing, drying, and detecting whether a coating is formed on the inner wall of the blind hole. The composition of the electroplating solution is: ZnCl 2 65g / L; KCl 155g / L; H 3 BO 3 21g / L; Surfactant A0.28g / L, the balance is water. Solution temperature 25°C, cathode current density 2.5A / dm 2 , pH value = 5.5, electroplating time 60min. The resulting coating has good compactness, good gloss and good corrosion resistance. Plating is formed on all inner walls of blind holes with a depth of 30mm, 40mm, and 50mm, but no plating is formed on the bottom of a blind hole with a depth of 60mm

Embodiment 2

[0048] Zinc alloy die-casting parts with different depths of blind holes were used as workpieces to be plated. The blind holes were circular holes with a diameter of 10 mm and depths of 30 mm, 40 mm, 50 mm and 60 mm, respectively.

[0049] The electroplating process is: degreasing, water washing, rust removal, water washing, electrogalvanizing, water washing, drying, and detecting whether a coating is formed on the inner wall of the blind hole. The composition of the electroplating solution is: ZnCl 2 65g / L; KCl 155g / L; H 3 BO 3 21g / L; Surfactant A 0.28g / L; TX-10 0.15g / L, the balance is water. Solution temperature 25°C, cathode current density 2.5A / dm 2 , pH value = 5.5, electroplating time 60min. Plating layers are formed on all the inner walls of the blind holes with different depths, and the obtained plating layers have good compactness, good gloss and good corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com