Phosphorus pig iron cast negative electrode assembled carbon block

A technology of phosphorus pig iron casting and cathode carbon block, which is applied in the field of aluminum electrolysis, can solve the problems of artificial extension legs not forming effective protection, accelerated cathode loss, aluminum electrolytic cell damage, etc., and achieves the effect of solving insufficient heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

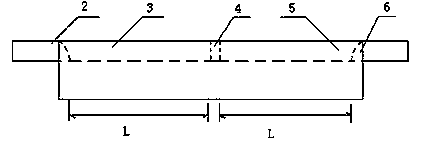

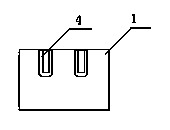

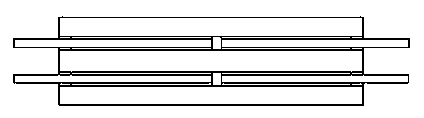

[0013] According to the size of the cathode carbon block structure, two sections of steel rod phosphorus pig iron casting cathode assembly carbon block (such as figure 1 As shown), the assembled carbon block structure is two steel rods with 2 gaps, the gap between the two sides of the steel rod corresponding to the middle gap of the anode, and the range outside the shape (except for the length L of the positive projection of the anode). , refractory materials, etc.) filling. The gap between the rest of the grooves and the steel rods is casted with pre-configured phosphorus pig iron. Long steel rod phosphorus pig iron casting cathode assembly carbon block (such as figure 2 As shown), the structure of the assembled carbon block is that the gap on both sides of the corresponding position of the middle seam of the two steel rods and the range outside the shape (beyond the length L of the positive projection of the anode) are filled with refractory materials such as asbestos, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com