Metal organic vapor phase deposition device

A vapor deposition, metal-organic technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of uneven film and low film rate, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

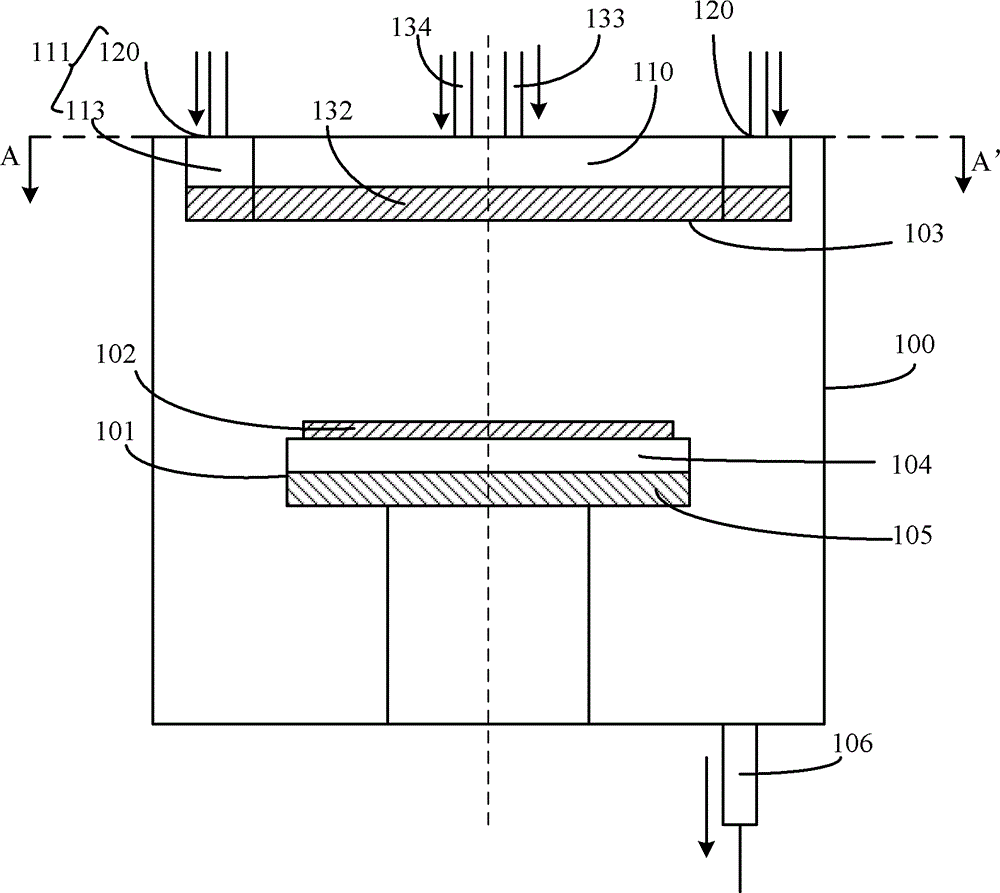

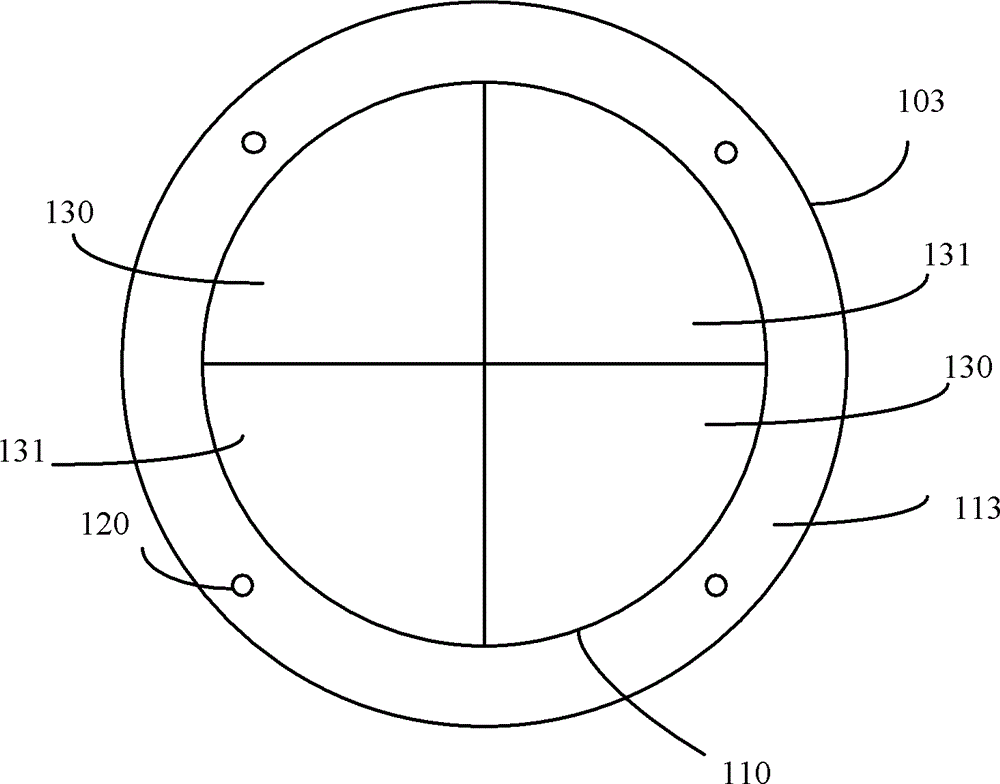

[0040] When using the existing metal-organic chemical vapor deposition device for thin film deposition process, the rotation speed of the base cannot be increased, and it is in a low speed state of less than 500RPM, the formation rate of the film is low, and the film formed in the central area of the base is uneven.

[0041] The inventors have found through research that the non-uniform film formed in the central area of the base at low rotational speed is caused by thermal convection eddies, which are caused by the temperature between the spray assembly and the base Poor, resulting in thermal convection of the gas to form a vortex, causing the reaction gas to fall back from the edge of the susceptor to the central area of the susceptor, resulting in uneven film.

[0042] In existing metal organic chemical vapor deposition devices, the distance from the spray assembly to the base varies according to the specific process requirements. When the process requires that the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com