Component manufacturing device and component manufacturing method

A technology for manufacturing devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

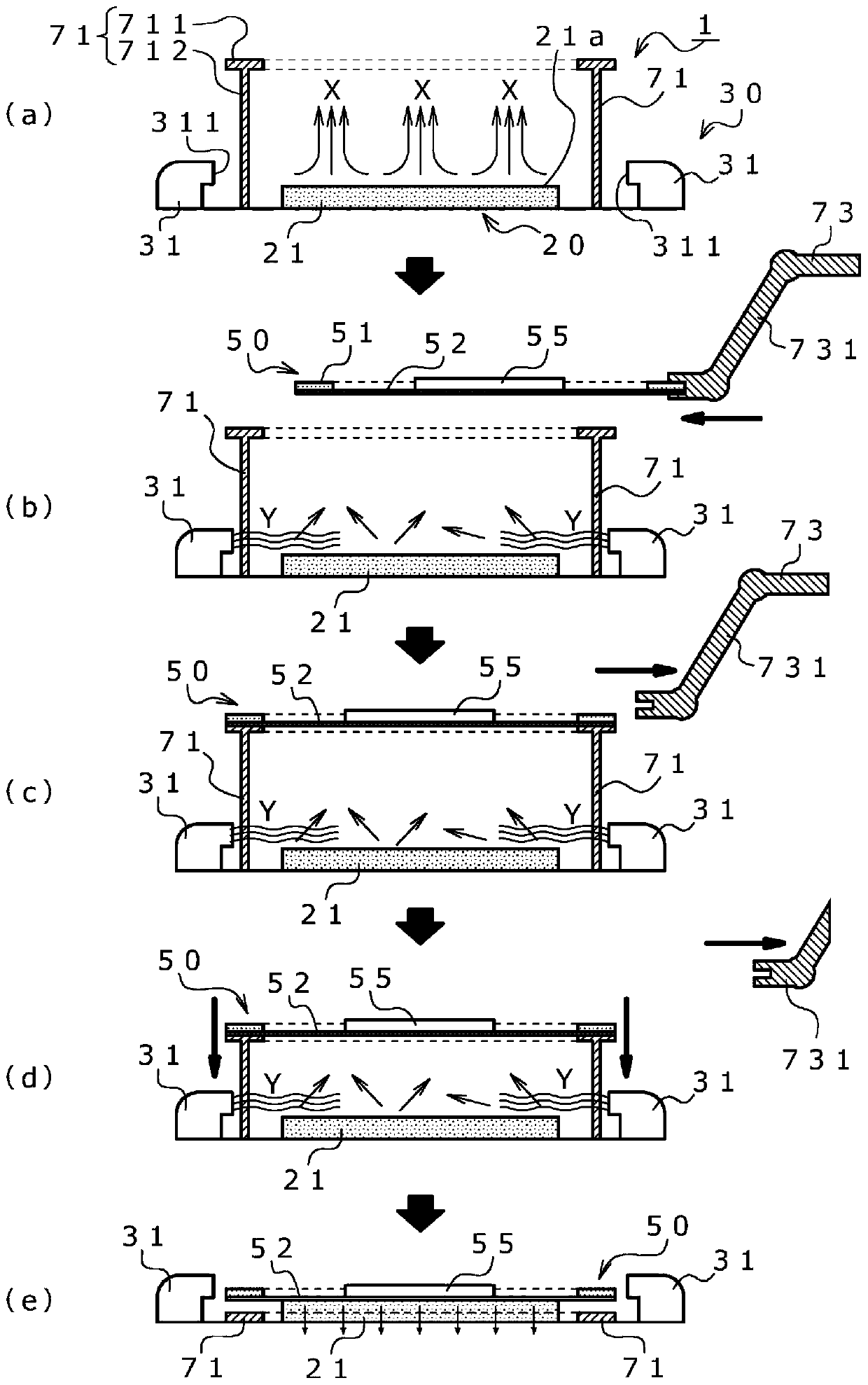

[0174] Hereinafter, the present invention will be specifically described by way of examples.

[0175] [1] Manufacture of part holder

[0176] Manufacture of the component holding film 52

experiment example 1

[0178] As the base layer 521, a polyester-based thermoplastic elastomer (TPEE) film having a thickness of 80 μm was prepared. Using this film, the tensile modulus E' was measured with a dynamic viscoelasticity measuring device (DMA: Dynamic Mechanical Analysis) (product name: RSA-3, manufactured by TA Instruments). Specifically, the sample size is 10 mm in width and 20 mm in length between chucks, measured from -50°C to 200°C under the measurement conditions of a frequency of 1 Hz and a heating rate of 5°C / min, and reading data for each temperature from the obtained data . Furthermore, the value at 25°C is defined as the tensile modulus E'(25), and the value at 160°C is defined as the tensile modulus E'(160), as shown in Table 1. Further, using these values, calculate the ratio R E1 (=E'(160) / E'(25)) and the results are shown in Table 1 together. As a result, the ratio R in Experimental Example 1 E1 is 0.13.

[0179] Next, a non-curable acrylic adhesive with a thickness o...

experiment example 2

[0181] As the base layer 521 , a polyester-based thermoplastic elastomer (TPEE) film with a thickness of 150 μm was prepared. This film is different from the film of Experimental Example 1 only in thickness. Otherwise, the member holding film 52 of Experimental Example 2 was obtained in the same manner as in Experimental Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com