Novel preparation method of schiff base oil well acidification corrosion inhibitor and application of preparation method

A technology of Schiff base oil well and acidizing corrosion inhibitor, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing the cost of acidizing fracturing mining technology, loss of tubing steel, and unsatisfactory strong acid anticorrosion effect, etc. Achieve the effects of wide application temperature range, good dispersion and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 36.96g of cinnamon oil and 19.84g of cyclohexylamine into a three-necked flask, then add 100g of the azeotrope of benzene and ethanol (67.6g of ethanol, 32.4g of benzene) and mix evenly, and heat up to the reflux temperature of the azeotrope of benzene and ethanol 65 ~ 70 ° C, after 5 hours of heat preservation reaction, the azeotrope of water, benzene and ethanol was distilled off under reduced pressure at 58 ~ 65 ° C, and then recrystallized twice with ethanol to obtain the compound 1-phenyl-3-(1 -cyclohexylamine)-1-propene, the product is obtained by liquid chromatography-mass spectrometry; then take 10g 1-phenyl-3-(1-cyclohexylamine)-1-propene, 0.5g cyclohexane Amine, 2g of methoxypropylamine, 3g of cetyltrimethylammonium chloride, 15g of N'N-dimethylformamide, and 69.5g of methanol can be mixed and stirred evenly.

[0024] Table 1 shows the evaluation results for N80 steel in 90°C, 15% HCl (weight) solution with different concentrations of corrosion inhibitors,...

Embodiment 2

[0028] Add 36.96g of cinnamon oil and 19.84g of cyclohexylamine into a three-necked flask, then add 100g of the azeotrope of benzene and ethanol (67.6g of ethanol, 32.4g of benzene) and mix evenly, and heat up to the reflux temperature of the azeotrope of benzene and ethanol 65 ~ 70 ° C, after 5 hours of heat preservation reaction, the azeotrope of water, benzene and ethanol was distilled off under reduced pressure at 58 ~ 65 ° C, and then recrystallized twice with ethanol to obtain the compound 1-phenyl-3-(1 -cyclohexylamine)-1-propene, the product is obtained by liquid chromatography-mass spectrometry; then take 15g 1-phenyl-3-(1-cyclohexylamine)-1-propene, 0.5g cyclohexane Amine, 1g of methoxypropylamine, 3g of cetyltrimethylammonium chloride, 20g of N'N-dimethylformamide, and 60.5g of methanol can be mixed and stirred evenly.

[0029] Table 2 shows the evaluation results of the corrosion inhibitor in 15% HCl (weight) solution for N80 steel at different temperatures, and th...

Embodiment 3

[0033] Add 36.96g of cinnamon oil and 19.84g of cyclohexylamine into a three-necked flask, then add 100g of the azeotrope of benzene and ethanol (67.6g of ethanol, 32.4g of benzene) and mix evenly, and heat up to the reflux temperature of the azeotrope of benzene and ethanol 65 ~ 70 ° C, after 5 hours of heat preservation reaction, the azeotrope of water, benzene and ethanol was distilled off under reduced pressure at 58 ~ 65 ° C, and then recrystallized twice with ethanol to obtain the compound 1-phenyl-3-(1 -cyclohexylamine)-1-propene, the product is obtained by liquid chromatography-mass spectrometry; then take 15g 1-phenyl-3-(1-cyclohexylamine)-1-propene, 2g cyclohexylamine , 1g of methoxypropylamine, 3g of cetyltrimethylammonium chloride, 15g of N'N-dimethylformamide, and 64g of ethanol can be mixed and stirred evenly.

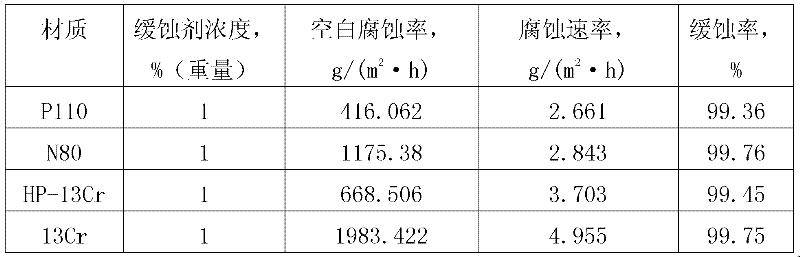

[0034] Table 3 shows the evaluation results for different materials in 15% HCl (weight) solution at 90° C. under the concentration of 1% (weight) corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com