Waterborne ultraviolet-heat dual-cured coating and preparation method thereof

A technology of water-based curing agent and ultraviolet light, which is applied in the direction of coating, etc., can solve the problems of foaming when wet, poor hardness, incomplete curing, etc., and achieve the effect of not easy to foam when wet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing a water-based ultraviolet-heat dual-curing coating, comprising:

[0067] adding and mixing epoxy resin, water-based curing agent and water-based epoxy acrylate oligomer to obtain a mixed solution;

[0068] Add photoinitiator, leveling agent and defoamer under stirring to obtain water-based UV-heat dual-curing coating;

[0069] Described water-based ultraviolet light-heat dual-curing coating comprises by weight parts:

[0070] 20-42 parts of epoxy resin;

[0071] 36.5-48.8 parts of water-based epoxy acrylate oligomer;

[0072] 31-63 parts of water-based curing agent;

[0073] Photoinitiator 2.9~7.5 parts;

[0074] Leveling agent 0.9~3.5 parts;

[0075] Defoamer 0.5-2.0 parts.

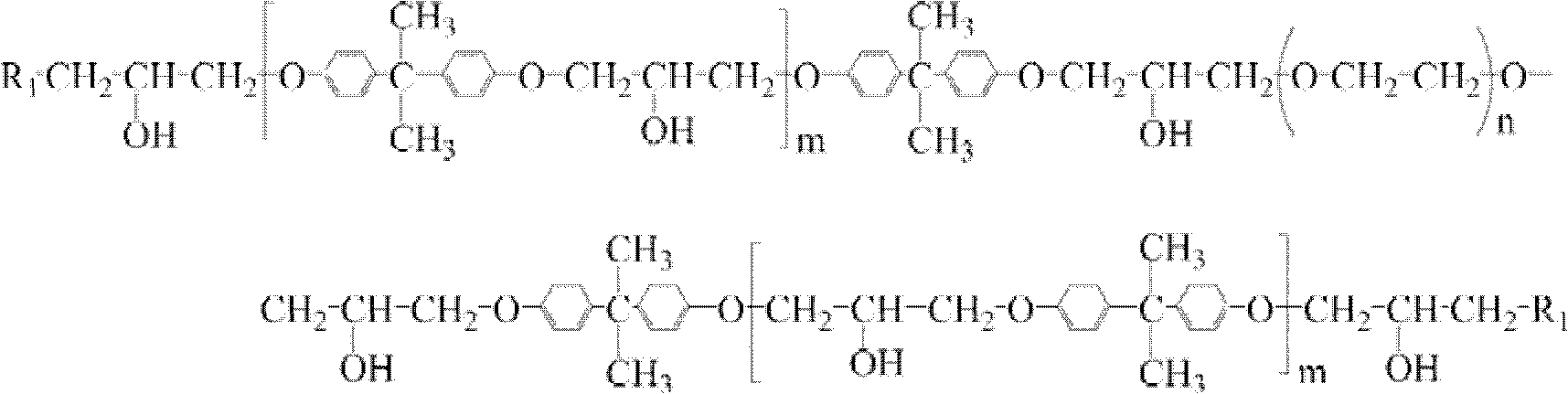

[0076] First prepare raw material; According to the present invention, described waterborne epoxy acrylate oligomer is preferably prepared by the inventor himself, and the preparation method is as follows:

[0077] Preparation metho...

Embodiment 1

[0086] With 20 grams of epoxy resin E44, 31 grams of water-based curing agent H206B and 36.5 grams of cationic water-based epoxy acrylate oligomer (R 1 = acrylic acid, R 2 = glacial acetic acid, m=2) join in the beaker, stir with the speed of 2000rpm 0.5 hour, under stirring, add 2.9 gram photoinitiator Darocur1173, 0.9 gram leveling agent BYK333 and 0.5 gram defoamer BYK055, continue with 2000rpm Stir at a rotating speed for 1.5 hours; obtain a water-based UV-heat dual-curing coating. Spray the prepared paint on the pre-polished, degreased, and derusted tinplate, light-cure it under a 3kw UV lamp for 20s, and then heat-cure it at 80°C for 2 minutes. The test results of paint film properties are shown in Table 1.

Embodiment 2

[0088] With 42 grams of epoxy resin E51, 63 grams of water-based curing agent H205B and 48.8 grams of non-ionic water-based epoxy acrylate oligomer (R 1 =acrylic acid, m=23, n=50) join in the beaker, stir with the speed of 2000rpm 1 hour, under stirring, add 7.5 grams of photoinitiator Irgacure184, 3.5 grams of leveling agent BYK366 and 2 grams of defoamer BYK088, continue Stir at 2000 rpm for 0.5 hour; obtain a water-based UV-heat dual-curing coating. Spray the prepared paint on the pre-polished, degreased, and derusted tinplate, light-cure it under a 3kw UV lamp for 30s, and then heat-cure it at 85°C for 3 minutes. The test results of paint film properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com