Single-component ketone-oxime-removing type silicon rubber sealant and preparation method thereof

A technology of sealant and silicone rubber, applied in adhesives, chemical instruments and methods, non-polymer adhesive additives, etc., can solve problems such as decrease in bond strength, achieve isolation from penetration damage, increase curing speed, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

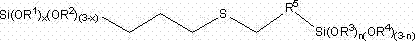

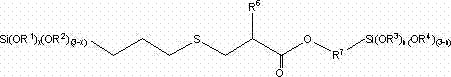

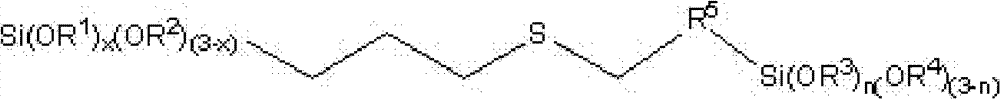

[0035] Add 100g of γ-mercaptopropyltrimethoxysilane and 75g of vinyltrimethoxysilane to a 250mL flask with a thermometer, a vacuum port and a N2 port, and heat the mixture in an oil bath at 70°C , vacuum and start stirring. When the temperature rose to 70°C, turn off the vacuum, add 1g of free radical initiator AIBN under the protection of N2, and stir at 70°C for 2h to synthesize a coupling agent with a special structure. The result shows that the mass percent content of the coupling agent with this special structure is more than 95%.

[0036] Select 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mpa.s, 15 parts of simethicone oil with a viscosity of 500mpa.s, 80 parts of calcium carbonate, and 10 parts of fumed white carbon black, and add them to the kneader In the process, start stirring and dispersing, dehydrate at 130°C~140°C, -0.09~-0.1MPa vacuum condition for 2~4 hours, then cool down to below 40°C. Transfer the above slurry to a planetary s...

Embodiment 2

[0038] Select 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mpa.s, 15 parts of simethicone oil with a viscosity of 500mpa.s, 80 parts of calcium carbonate, and 10 parts of fumed white carbon black, and add them to the kneader In the process, start stirring and dispersing, dehydrate at 130°C~140°C, -0.09~-0.1MPa vacuum condition for 2~4 hours, then cool down to below 40°C. Transfer the above slurry to a planetary stirring tank, add 10 parts of vinyl tributylketoxime silane under the protection of N2, 1 part of special coupling agent synthesized in Example 1, and 1 part of γ-aminopropyltrimethoxysilane , 0.3 part of dibutyltin dilaurate, stirred under vacuum condition of -0.09~-0.1MPa until uniform without bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com