Material special for level-A fire-proof aluminum-plastic board core and preparation method thereof

A technology for aluminum-plastic panels and special materials, which is applied in the field of A-class fire-resistant aluminum-plastic panel core materials and its preparation, can solve the problems of polyolefin physical and mechanical performance deterioration, large addition amount, etc., and achieve shortening molding time, The effect of eliminating smoke and preventing molten droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] According to the formula of Example 1 in Table 1, the specific preparation steps of the Class A fire-resistant aluminum-plastic plate core special material and its preparation method are as follows:

[0025] (1) Dry the raw magnesium hydroxide powder in a constant temperature drying oven at 120°C for 2 hours;

[0026](2) Use polymer compatibilizer, crosslinking agent, dispersant and coupling agent to pretreat the dried magnesium hydroxide, and the selected polymer compatibilizer PS-g- (epoxy modified PS) , cross-linking agent 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, dispersant polyethylene wax, silane coupling agent (AMEO) and magnesium hydroxide are dried and mixed in a high-speed mixer Evenly, the pretreated magnesium hydroxide flame retardant is obtained. The stirring speed of the high-speed mixer is 2000r / min, the stirring time is 10min, and the mixing temperature is 120°C;

[0027] (3) According to the formula in Table 1, weigh high-compatibility resin or resi...

Embodiment 2~5

[0032] Embodiments 2 to 5 are prepared according to the formula in Table 1, and the implementation process is the same as in Embodiment 1.

[0033] Table 1 embodiment formula composition

[0034]

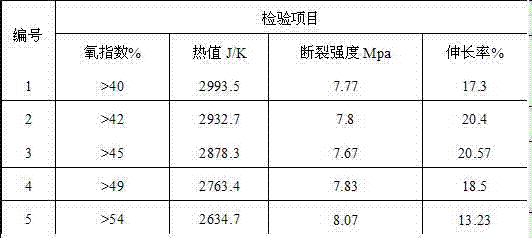

[0035] Table 2 Performance indicators of special materials for the core layer of Class A fire-resistant aluminum-plastic panels

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com