Preparation method of quaternary copolymer block organic silicon oil

A quaternary copolymerization block and silicone oil technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as stuffy wearing feeling, demulsification and oil leaching, difficult to wash, etc., achieve good chemical stability, solve the problem of sticking Roller, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The preparation method of the quaternary copolymerized block silicone oil of the present invention comprises the following steps:

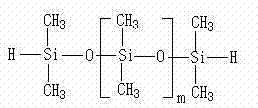

[0064] A, preparation of intermediate I

[0065]Add a certain amount of octamethylcyclotetrasiloxane into the four-necked flask, raise the temperature while stirring, to about 30°C, add a certain amount of catalyst (concentrated sulfuric acid) to react, and add a certain amount of hydrogen after about 10 minutes Double head; continue to keep warm for 4-5 hours. After passing the test, add soda ash to neutralize excess acid, and control the pH value to 6-7. Stand still, precipitate, and take the upper transparent oily body. stand-by.

[0066] During the preparation process, the catalyst accounts for 1-2% (weight ratio) of the main monomer, and the hydrogen-containing double head accounts for 4% (weight ratio) of the main monomer depending on the size of the synthetic molecular weight.

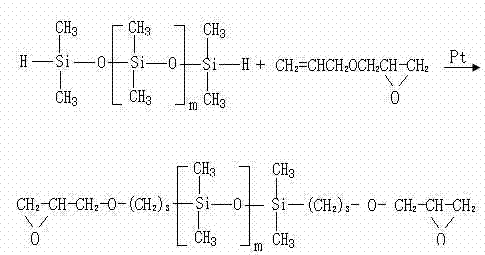

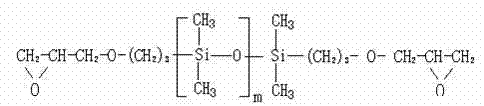

[0067] B. Intermediate II

[0068] Add a certain a...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is only:

[0075] A, the octamethylcyclotetrasiloxane in the preparation intermediate I is changed to dimethylhexasiloxane, and the quality of the hydrogen-containing head-sealing agent in the step A is 3.0% of the quality of the polysiloxane, and the rest constant. B and C remain unchanged.

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is only:

[0078] The mass of the hydrogen-containing head sealant in the step A is 5.0% of the mass of polysiloxane.

[0079] The performance index of the finished quaternary copolymerization block silicone oil finished product is as follows:

[0080] Appearance: Pale yellow transparent viscous liquid

[0081] Ionicity: weak cationic / non-ionic

[0082] pH: 5-7

[0083] Solubility: It can be mixed with cold and hot water in any proportion without emulsifier.

[0084] Compatibility: Can be mixed with non-ionic and cationic additives

[0085] Storage stability: The storage stability period is more than 6 months.

[0086] Process conditions for hand finishing of quaternary copolymerized block silicone oil:

[0087] Dipping method: Dosage (relative to the amount of fabric): 2-3% after diluting 10 times, temperature: 50-60°C; time: 20-30min; dehydration, drying, and setting.

[0088] Padding met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com