Fluorosilicone oil and preparation method of fluorosilicone oil

A technology of fluorosilicone oil and molecular formula, which is applied in the field of fluorosilicone oil and its preparation, can solve problems such as failure to meet high performance requirements, insufficient lubrication and three defenses, etc., achieve excellent high and low temperature resistance, simple preparation method, and improved oil and solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

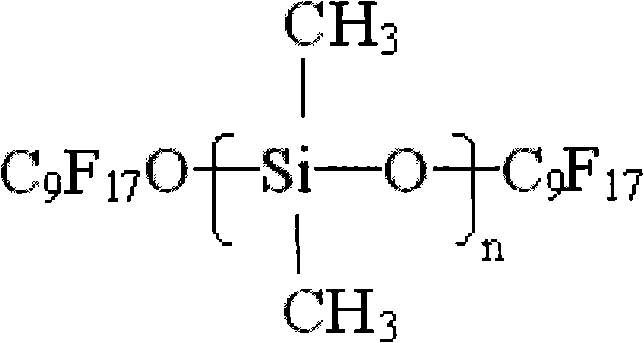

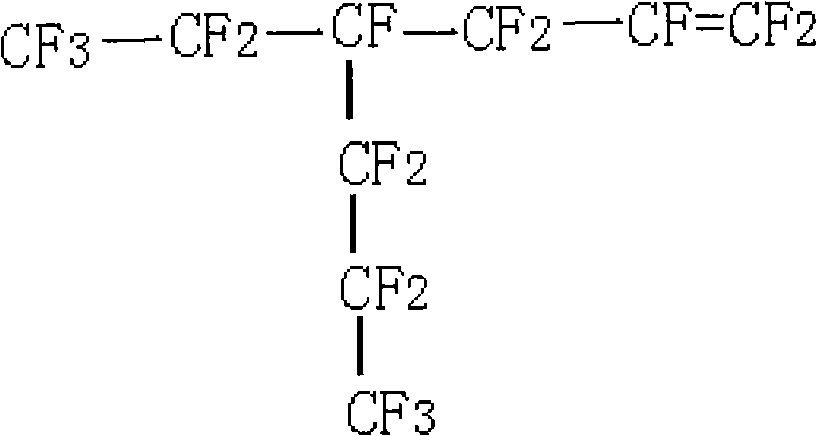

[0019] The gist of the present invention is to prepare the fluorosilicone oil of the present invention, which has an oxygen ether and a silicon bond, its fluorocarbon chain is a branched 9 carbons, and its silicon part is a hydroxyl-containing organosilicon oligomer. The fluorosilicone oil prepared by introducing long-chain fluorocarbon group polysiloxane molecular structure combines the dual properties of organic silicon and fluorocarbons, which not only maintains the inherent excellent high and low temperature resistance, viscosity and temperature properties of silicone oil, but also It can make fluorosilicone oil have three-proof properties. The present invention will be further described below in conjunction with specific embodiment, but specific embodiment does not limit the present invention in any way

[0020] Put 80 kg of organosilicon hydroxy silicone oil, 15 kg of solvent, 20 kg of fluorine monomer, and 1 kg of catalyst into the reaction kettle, and react with alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com