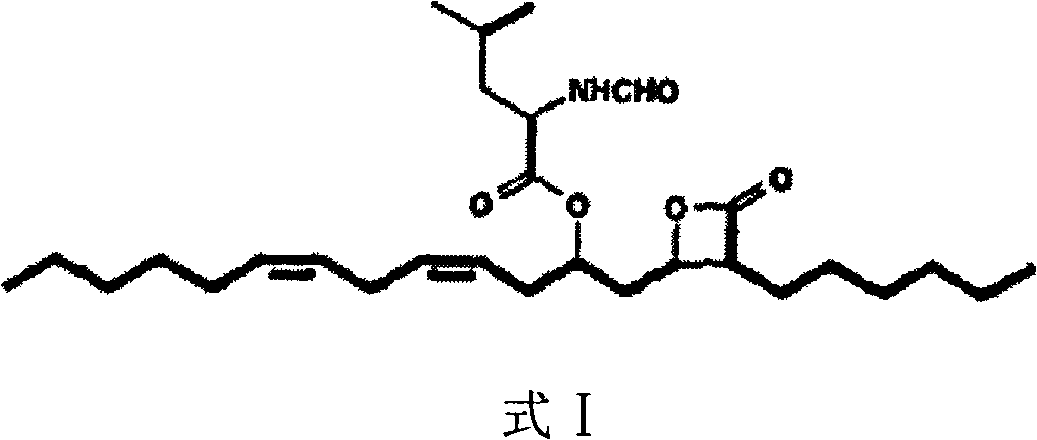

Method for purifying lipstatin

A purification method, the technology of riprex, which is applied in the field of riprestatin purification, can solve the problems of health hazards of operators, large loss of target products, and many steps in the extraction process, and achieve high extraction rate, low cost, and few times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] When the fermentation broth is directly spray-dried, a centrifugal nozzle spray dryer is used. The gas inlet temperature of the spray dryer is controlled at 40°C, the gas outlet temperature is controlled at 35°C, the temperature of the material in the tower is kept at 40°C, and the pressure in the tower is kept at 250kPa to obtain solid fermented dry bacteria powder with a particle size of 50 mesh.

[0181] Put the above fine powder into supercritical CO 2 In the extraction kettle, adjust the extraction temperature, pressure, time, control CO 2 Flow rate for extraction, wherein: extraction kettle temperature 35°C, pressure 40.0MPa, time 4h, CO 2 The flow rate is 30L / h. The entrainer ethanol (the ratio of the volume of the entrainer to the weight of the fine powder is 5:1 (L:Kg)) was added to the extraction kettle, and its flow rate was set at 4 L / h. Then set the separation temperature of the first separation tank to 30° C. and the separation pressure to 8 MPa for the...

Embodiment 2

[0190] Spray-dry the fermentation broth directly using a centrifugal nozzle spray dryer. The gas inlet temperature of the spray dryer is controlled at 60°C, the gas outlet temperature is controlled at 50°C, the temperature of the material in the tower is kept at 55°C, and the pressure in the tower is kept at 350kPa , to obtain solid fermented and dried bacteria powder with a particle size of 80 mesh.

[0191] Put the above fine powder into supercritical CO 2 In the extraction kettle, adjust the extraction temperature, pressure, time, control CO 2 Flow rate for extraction, wherein: extraction kettle temperature 60°C, pressure 20.0MPa, time 2h, CO 2 The flow rate is 10L / h. The entrainer ethanol (the ratio of the volume of the entrainer to the weight of the fine powder is 3:1 (L:Kg)) was added into the extraction kettle, and its flow rate was set at 2 L / h. Then set the separation temperature of the first separation tank to 50° C. and the separation pressure to 5.5 MPa for the ...

Embodiment 3

[0200] The fermentation liquid is directly spray-dried using a centrifugal nozzle spray dryer. The gas inlet temperature of the spray dryer is controlled at 50°C, the gas outlet temperature is controlled at 40°C, the temperature of the material in the tower is kept at 45°C, and the pressure inside the tower is kept at 300kPa , to obtain solid fermented and dried bacteria powder with a particle size of 40 mesh.

[0201] Put the above fine powder into supercritical CO 2 In the extraction kettle, adjust the extraction temperature, pressure, time, control CO 2 Flow rate for extraction, wherein: the temperature of the extraction kettle is 40°C, the pressure is 30.0MPa, the time is 3h, CO 2 The flow rate is 30L / h. The entrainer ethanol (the ratio of the volume of the entrainer to the weight of the fine powder is 3:1 (L:Kg)) was added into the extraction kettle, and its flow rate was set at 2 L / h. Then set the separation temperature of the first separation tank to 40° C. and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com