Method for producing p-tert-Butyltoluene by using mordenite for catalyzing toluene and tertiary butanol

A technology of p-tert-butyltoluene and mordenite, which is applied in the field of production of p-tert-butyltoluene, can solve the problems of environmental pollution, high production intensity, and low yield, and achieve the effect of overcoming corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

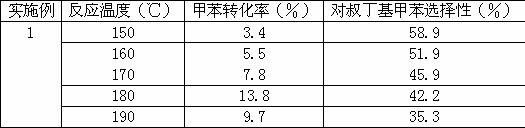

Embodiment 1

[0012] Reaction conditions: the molar ratio of raw materials is 1:4 (toluene: tert-butanol), and the volumetric liquid space velocity is 2 ml / g cat ·H, the catalyst is a mordenite molecular sieve catalyst that has been activated at 550°C for 3 hours. The gas-solid phase continuous reaction is carried out at different reaction temperatures for 10 hours. The results are shown in Table 1.

[0013] Attached Table 1 Catalytic performance at different reaction temperatures

[0014]

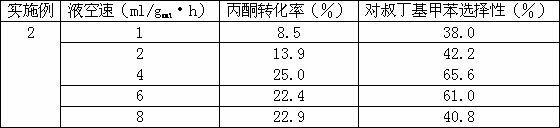

Embodiment 2

[0016] Reaction conditions: The reaction temperature is 180℃, the molar ratio of raw materials (toluene: tert-butanol) is 1:4, the catalyst is mordenite molecular sieve catalyst which has been activated at 550℃ for 3 hours, and the gas-solid phase continuous reaction is carried out at different liquid space velocities. 10 hours, the results are shown in Table 2.

[0017] Attached Table 2 Catalytic performance under different liquid space velocity

[0018]

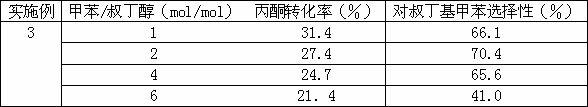

Embodiment 3

[0020] Reaction conditions: feed space velocity 4 ml / g cat ·H. The reaction temperature is 180°C. The catalyst is a mordenite molecular sieve catalyst that has been activated at 550°C for 3 hours. Different raw material ratios (toluene: tert-butanol) are used for continuous gas-solid reaction for 10 hours. The results are shown in Table 3.

[0021] Attached Table 3 Catalytic performance under different toluene / tert-butanol ratios

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com