Process for preparing vacuum glass

A technology of vacuum glass and preparation technology, which is applied in the field of glass preparation technology, which can solve the problems of increasing the distance between products up and down, without heat conduction and convection, and increasing production costs, so as to increase the placement space and quantity, shorten manufacturing time, and reduce electric energy. and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings. It should be understood, however, that elements, structures and characteristics described in one embodiment may be beneficially incorporated into other embodiments without further recitation.

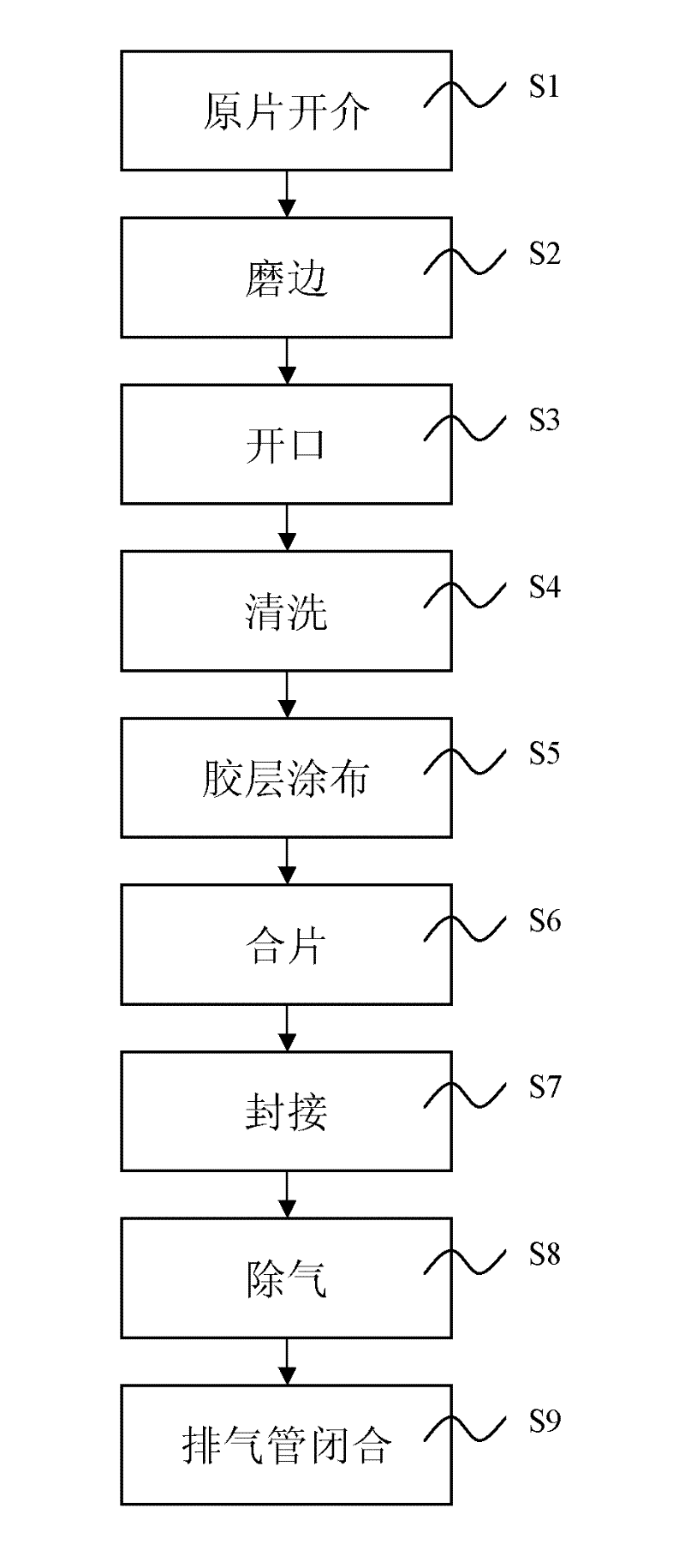

[0054] refer to figure 1 , the vacuum glass preparation process of the present invention includes the original sheet opening step S1, edging step S2, opening step S3, cleaning step S4, adhesive layer coating step S5, lamination step S6, sealing step S7, degassing step S8 And the exhaust pipe closing step S9.

[0055] In the original sheet opening step S1, the glass original sheet is opened into a first glass 10 and a second glass 20 according to the size requirements. The original glass sheet can be commonly used glass, such as float glass, wire glass, coated glass, colored glass and the like. The opening tool is preferably an automatic cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com