Treatment method of excess sludge

A technology of excess sludge and treatment method, applied in biological sludge treatment and other directions, can solve the problems of low COD concentration in influent water, hindering the hydrolysis of easily degradable substances in cells, and failing to reach the optimal range of anaerobic digestion. Low organic and dissolved COD content, improved operational stability and treatment efficiency, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

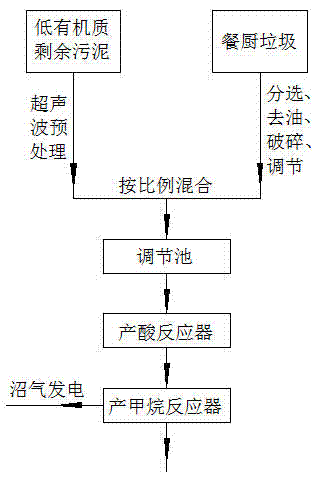

Method used

Image

Examples

Embodiment 1

[0031] The concentrated residual sludge produced by the A / O process of a sewage treatment plant has a VS of 15.91g / L and a VS / TS value of 58.19%. Kitchen waste is mainly composed of rice, meat and a small amount of vegetables, and the VS value is 82.75g / L , VS / TS (organic matter content / total solid content) is 99.22%. After the sludge is cracked at a frequency of 40kHz and an acoustic energy density of 0.25w / mL for 45 minutes, according to the mass ratio of remaining sludge to kitchen waste (total organic matter After mixing with mass ratio) 1:1 and volume ratio about 5:1, its VS value is 24.41g / L, and VS / TS can reach 70.53%.

[0032] When the organic volume load is 1.220kgVS / m 3 ·Mesophilic anaerobic fermentation is carried out under d, the pH of the acid production phase is maintained at about 4.75, and the total volatile organic acids are at 3500mgC 2 h 4 02 / L, the pH of the gas phase is maintained at about 7.03, and the total volatile organic acids are at 130mgC 2 h 4...

Embodiment 2

[0034] A sewage treatment plant A 2 The VS of the concentrated residual sludge produced by the / O process was 18.02g / L, and the VS / TS value was 59.68%. Organic matter content / total solid content) is 90%. After the sludge is cracked at a frequency of 40kHz. and an acoustic energy density of 0.25w / mL for 30 minutes, according to the mass ratio of the remaining sludge to the kitchen waste (the ratio of the total mass of organic matter) ) 1.5:1, the volume ratio is about 6.3:1 after mixing, the VS value is 25.18g / L, and the VS / TS can reach 68.77%.

[0035] When the organic volume load is 1.260kgVS / m 3 Under d, mesophilic anaerobic fermentation is carried out, the pH of the acid production phase is maintained at about 4.83, and the total volatile organic acids are at 3260mgC 2 h 4 0 2 / L, the pH of the gas production phase is maintained at about 7.10, and the total volatile organic acids are at 130mgC 2 h 4 0 2 / L or less. The average removal rate of organic matter by the s...

Embodiment 3

[0037] A sewage treatment plant A 2 The concentrated residual sludge produced by the / O process has a VS of 19.85g / L and a VS / TS value of 60.68%. Kitchen waste is mainly composed of rice, meat and a small amount of vegetables with a VS value of 80.05g / L and a VS / TS ( Organic matter content / total solid content) is 96.61%. After the sludge is cracked at a frequency of 40kHz. and an acoustic energy density of 0.25w / mL for 30 minutes, according to the mass ratio of the remaining sludge to the food waste (the ratio of the total mass of organic matter) 3:1, the volume ratio is about 12.1:1 after mixing, the VS value is 24.62g / L, and the VS / TS can reach 68.13%.

[0038] The organic volume load is 1.222kgVS / m 3 Under d, mesophilic anaerobic fermentation was carried out, the pH of the acid production phase was maintained at about 5.71, and the total volatile organic acids were at 1890mg C 2 h 4 0 2 / L, the pH of the gas phase is maintained at about 7.15, and the total volatile orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com