Treatment method of wastewater from processing of betel nuts

A technology for processing waste water and treatment methods, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult biochemistry, low operating costs, and substandard treatment of betel nut processing waste water, etc. problems, to achieve the effect of easy promotion and application, low engineering cost and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further clarified through the detailed description of specific embodiments below, but it is not intended to limit the present invention, but only for illustration.

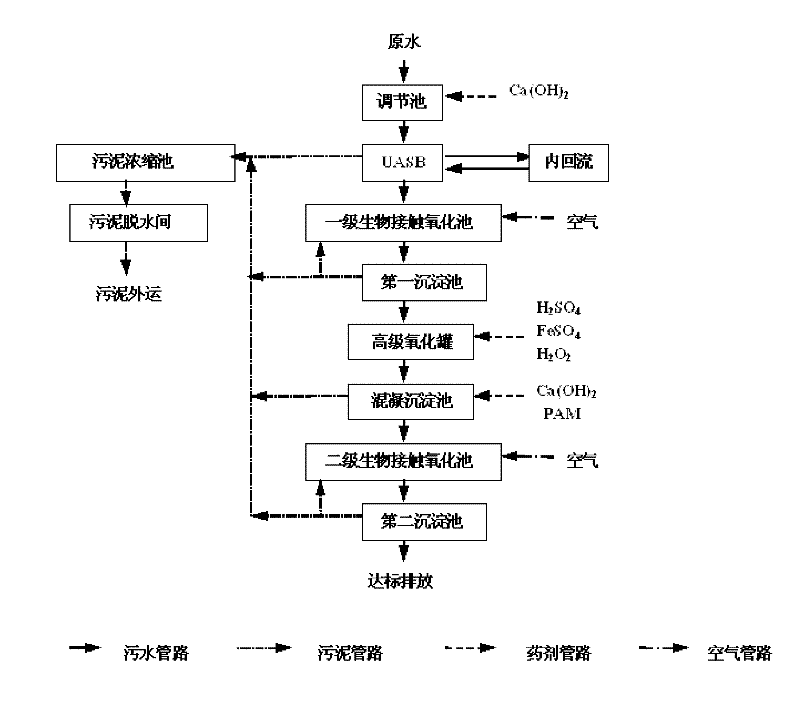

[0028] The present invention is implemented in an enterprise that processes 2,500 tons of betel nuts per year. According to the combined process route of the present invention, a regulating tank, a UASB reactor, a primary biological contact oxidation tank, a first sedimentation tank, an advanced oxidation tank, and a coagulation tank are respectively built. Pool, secondary biological contact oxidation tank and second sedimentation tank.

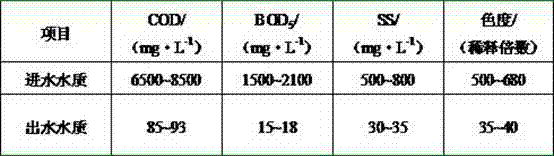

[0029] This implementation of betel nut processing wastewater, the daily wastewater treatment volume is 50m 3 , The wastewater quality is: COD 6500~8500mg / L, BOD 1500~2100 mg / L, SS 500~800mg / L, chroma (dilution multiple) 500~680 times.

[0030]

[0031]

[0032] 1) Sieve screen gap 3mm, manual screen. It is mainly to remove betel nut sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com