PVC (Polyvinyl Chloride) mother liquor treatment method based on MBR (Membrane Bioreactor) technique

A treatment method and reactor technology are applied in the field of treating PVC mother liquor by using MBR reactor technology, which can solve the problems of high ozone unit cost, difficult degradation of organic matter, difficult production and application, etc., so as to improve the effect of biochemical treatment and reduce sludge. The effect of stable discharge and effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

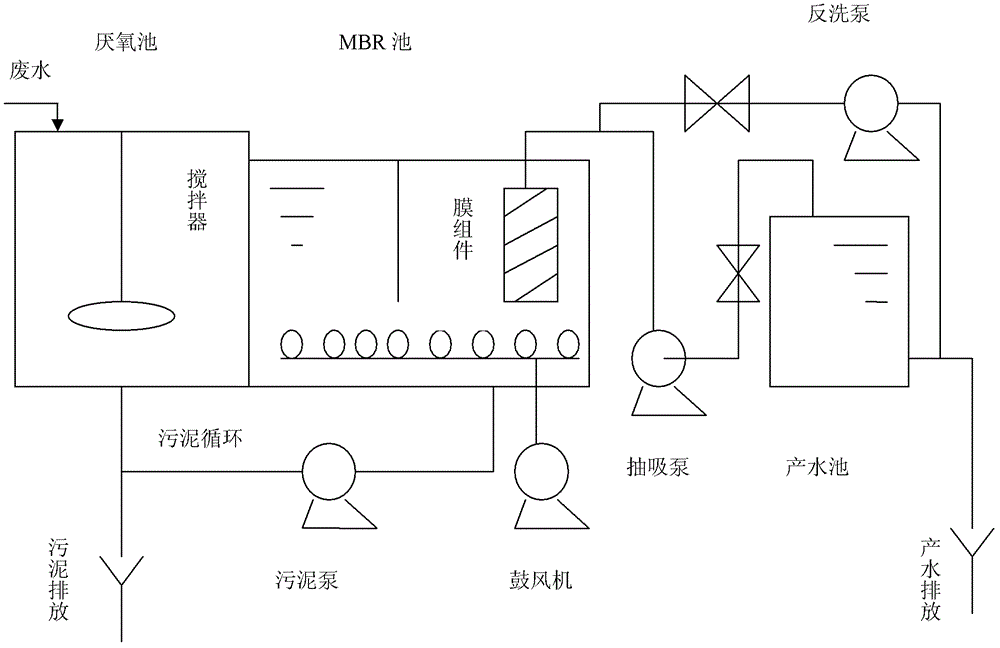

[0047] According to attached figure 1 In the process shown, the PVC mother liquor of the manufacturer is used as the processing object.

[0048] First, the PVC mother liquor with a COD of 600mg / l and a PVA of 12mg / l is subjected to anaerobic reaction treatment with PVA-degrading bacteria for 10 hours. The anaerobic reaction controls the reaction temperature at 35°C and controls the dissolved oxygen at 0.1-0.2mg / l. Between; then the above-mentioned effluent through the anaerobic reaction enters the MBR reactor for aerobic treatment, and the MBR reactor contains bacillus. After treatment, the COD in the PVC mother liquor is 28mg / l, and the PVA is extremely small.

Embodiment 2

[0050] According to attached figure 1 In the process shown, the PVC mother liquor of the manufacturer is first treated, so that the COD in it is 500mg / l, the PVA is within 10mg / l, the pH is adjusted to 7-8, and the temperature is between 30-33°C. And the cultivation process of the PVA-degrading bacteria in this embodiment is: inoculate the PVC mother liquor from the digested sludge, control the dissolved oxygen 0.1-0.2mg / l, and the temperature is at 30-35°C; add glucose and phosphoric acid in the early stage of sludge acclimatization Potassium dihydrogen, then gradually reduce the glucose consumption and gradually increase the PVC mother liquor inlet and outlet water flow, when the PVA degrading bacteria make the TOC removal rate in the PVC mother liquor reach more than 30% and then use as the PVA degrading bacteria of the present embodiment, when carrying out degradation treatment, A stirrer action is required in the reactor to enhance the effect. And the preparation process...

Embodiment 3

[0054] In a method similar to Example 2, the PVC mother liquor of the manufacturer is treated first, so that the COD therein is 500 mg / l, the PVA is within 10 mg / l, the pH is adjusted to be 7-7.5, and the temperature is between 32-35 ° C. The cultivation process of PVA-degrading bacteria in this example is: inoculate PVC mother liquor from digested sludge, control dissolved oxygen 0.1-0.2mg / l, and temperature at 30-35°C; add glucose and dihydrogen phosphate in the early stage of sludge acclimatization Potassium, then gradually reduce the amount of glucose and gradually increase the flow of water in and out of the PVC mother liquor. When the PVA degrading bacteria make the TOC removal rate in the PVC mother liquor reach more than 30%, use it as the PVA degrading bacteria of the present embodiment, and select the PVA degrading bacteria as the regular shape of Brevibacterium. And the preparation process of the bacillus in the MBR reactor is: add potassium dihydrogen phosphate in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com