Roll-on/roll-off shipping method for long large steel box girder segment across obstacles

A technology that crosses obstacles and grows sections, and is applied in the directions of storage devices, transportation and packaging, loading/unloading, etc., and can solve the limitations of shipping conditions, the heavy weight of long sections, and the large size of long sections of steel box girders And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

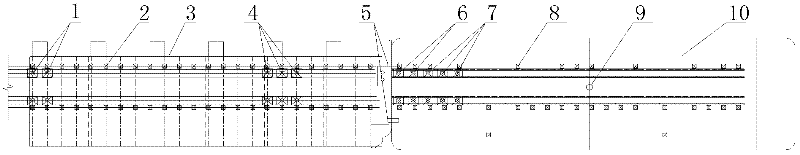

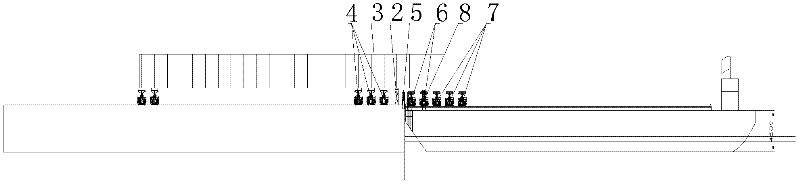

[0023] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0024] The method for ro-ro loading of long sections of steel box girder over obstacles in the present invention is a new technology of ro-ro loading of steel box girder long sections on the shore and ship for relay transfer method: firstly, the hydraulic slipway on the shore is used. After the cantilever end of the steel box girder is moved to the top of the ship deck, the section is transferred to the transport ship by the hydraulic truck on the ship. The super-steel box girder long section span barrier is moved to the ship, and the floating state of the transport ship is adjusted by using the ballast water of the transport ship itself, so as to overcome the problem of the height difference between the deck and the slipway of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com