Method for identifying fractal features of friction boundary of rear cutter face of cutter tooth of high-energy-efficiency milling cutter

A technology of fractal features and identification methods, which is applied in special data processing applications, instruments, complex mathematical operations, etc., and can solve the problems of unquantifiable revealing of dynamic change features and neglect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0074] Embodiment 1: A method for identifying the fractal characteristics of the frictional boundary of the flank of a high-energy-efficiency milling cutter, which specifically includes the following steps:

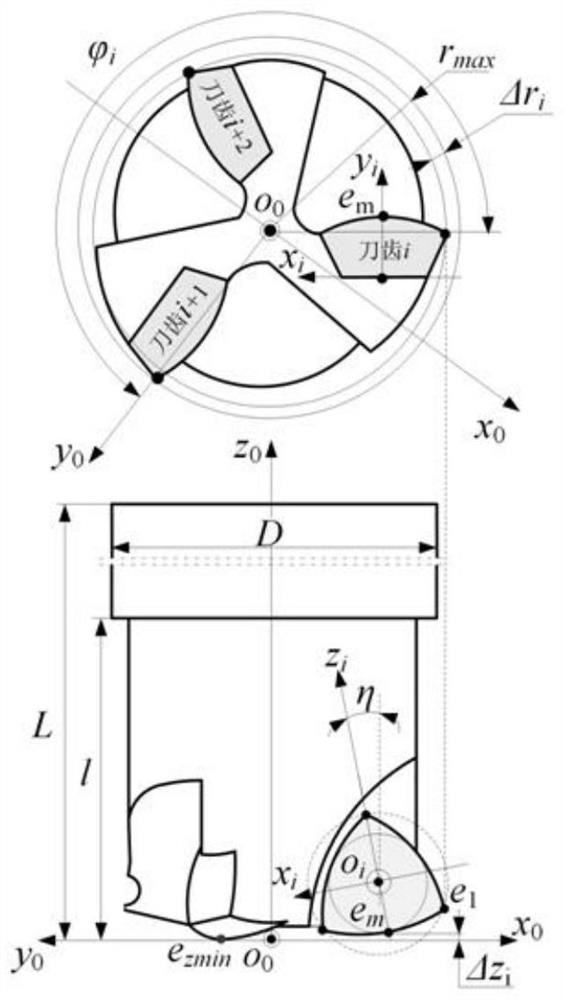

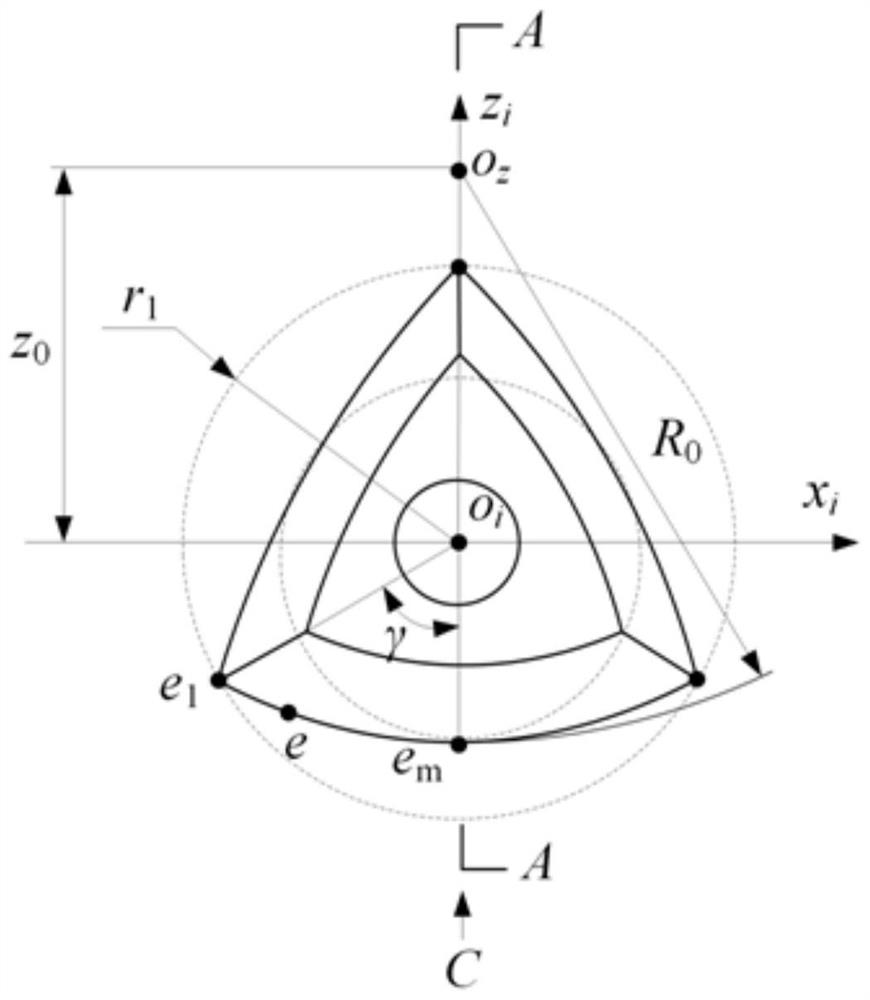

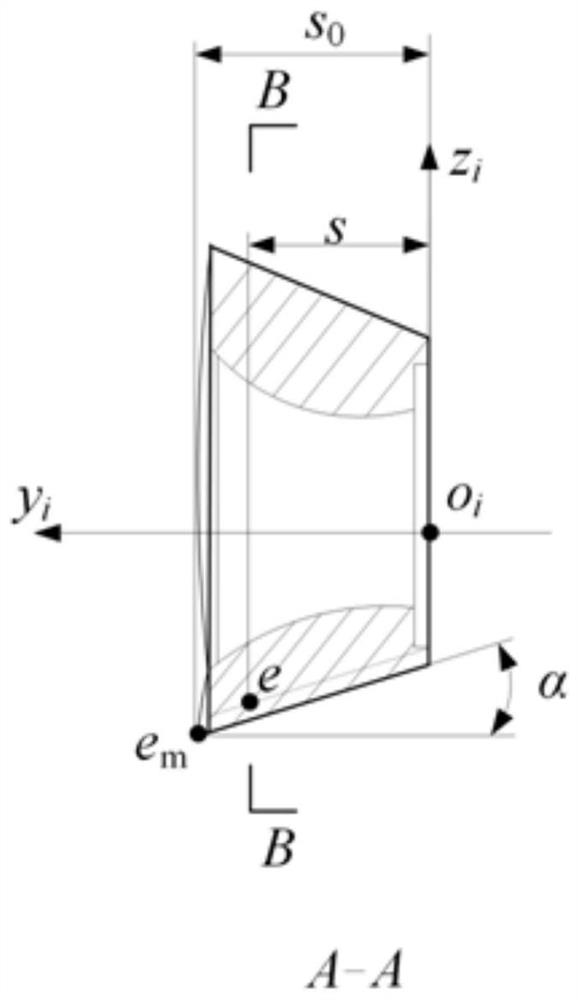

[0075] Step S1, constructing a high-energy-efficiency milling cutter coordinate system and its cutter tooth flank equation;

[0076] Solve the milling cutter and its cutter tooth structure and flank equation to obtain the cutter flank equation and cutter cutting edge equation;

[0077] Step S2, constructing a high-energy-efficiency milling cutter tooth flank friction boundary measurement coordinate system;

[0078] Step S3, solving the fractal characteristic parameters of the friction boundary of the cutter tooth flank;

[0079] Under the high-energy-efficiency milling cutter flank friction boundary measurement coordinate system constructed in step S2, the projection surface of the flank flank is intercepted, the instantaneous friction boundary feature points are extract...

specific Embodiment approach 2

[0208] Specific implementation mode two: the identification method of the fractal characteristics of the friction boundary of the flank of the high-energy-efficiency milling cutter tooth, which also includes the calculation of the cumulative friction boundary of the flank of the milling cutter tooth and its fractal characteristic verification method. The specific implementation method is:

[0209] (1) Identify and characterize the upper boundary curve formed by the maximum friction boundary of instantaneous friction in each cycle of the cutter tooth i when the milling cutter cuts in, cuts in, and cuts out respectively. Figure 35 shown.

[0210] According to the above analysis, the upper boundary of cumulative friction on the flank of milling cutter teeth is shown in Equation (37).

[0211] V s (U)=V s (U,t) (37)

[0212] In formula (37), V s (U,t) is the V coordinate value of the instantaneous friction upper boundary curve on the flank of the milling cutter tooth flank at...

specific Embodiment approach 3

[0229] Specific implementation method three: a method for identifying the fractal characteristics of the friction boundary of the flank of a high-energy-efficiency milling cutter;

[0230] In order to verify the effectiveness and applicability of the fractal characterization and identification method for the flank friction boundary of high-energy-efficiency milling cutters. Design and implement high-energy-efficiency milling cutters. Use the same milling cutters, workpieces, installation methods, cutting methods, and detection methods as those in Scheme 1. Keep the cutting depth and cutting width unchanged. Increase the milling cutter speed and change the tooth error distribution to change the According to the vibration characteristics of milling, the feed per tooth is correspondingly reduced to keep the cutting efficiency constant, and the fractal characteristic parameters of the friction boundary of the cutter tooth flank are calculated. The second scheme is shown in Table 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com