Plate-type conveying chain failure early-warning method and plate-type conveying chain failure early-warning system

A fault warning and conveyor chain technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of inability to detect the running condition of the chain in time, and the plate conveyor chain is stuck, so as to ensure the continuity of production, The effect of ensuring operation and reducing losses caused by failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

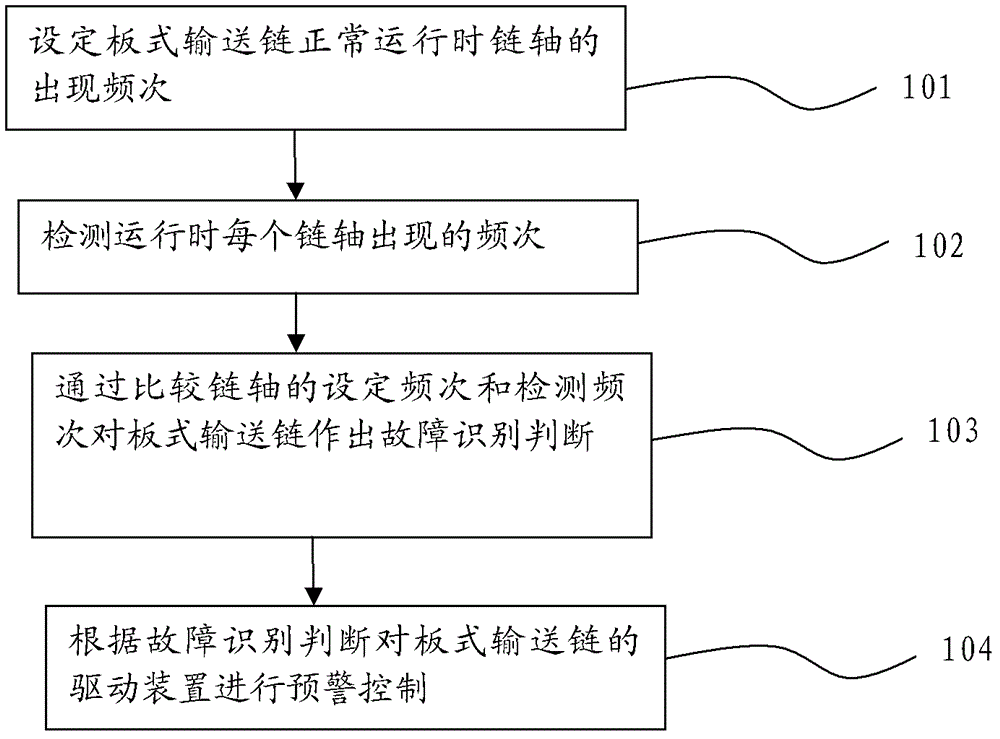

[0047] refer to figure 1 As shown, the plate conveyor chain fault early warning method of the present invention comprises:

[0048] 【101】Set the occurrence frequency of the chain shaft when the plate conveyor chain is running normally.

[0049] According to the running speed of the plate conveyor chain and the distance between two adjacent chain shafts, set the frequency of each chain shaft passing a fixed position during normal operation. The conveying speed of the plate conveyor chain and the distance between the chain shafts are different, so the frequency of occurrence of the chain shafts is different, which should be set according to the actual situation.

[0050] [102] Detect the frequency that each chain shaft passes through. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com