Speed-reducing wheel-rim driving system using motor as power vibration absorber

A dynamic vibration absorber and wheel-side drive technology, which is applied in the power plant, motion deposition, elastic suspension, etc., can solve the problems that the mass of the dynamic vibration absorber should not be too large, increase the curb weight of the whole vehicle, and reduce the driving mileage. Improved vertical performance, low manufacturing cost and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

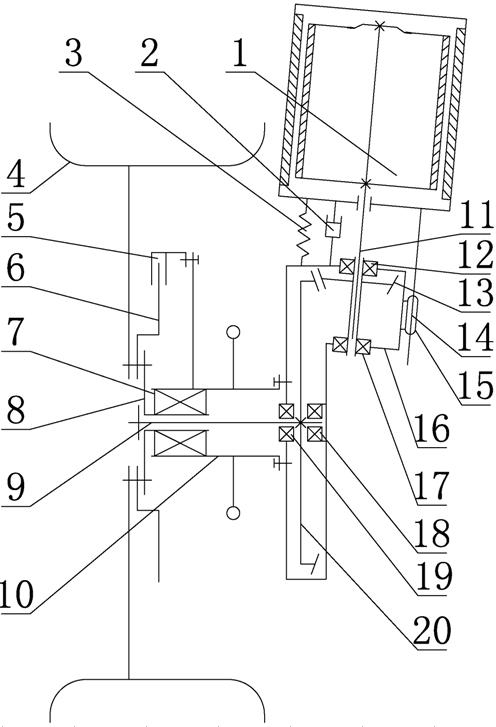

[0034] Please refer to the accompanying drawings for a further description of the present invention.

[0035] figure 1 It is a 1 / 4 vehicle two-degree-of-freedom vibration model diagram of a traditional wheel-drive electric vehicle, and the mass m3 of the motor 1 is the unsprung mass.

[0036] figure 2 It is a three-degree-of-freedom vibration model diagram of a 1 / 4 vehicle equipped with a shock absorber. The motor acts as a deceleration wheel drive system for a dynamic shock absorber, where m2 is 1 / 4 of the body mass, and m1 is the unsprung mass, mainly including the wheels , wheel rim 4, braking system rotating element 6, braking system non-rotating element 5, half shaft 9, steering knuckle 10, small bevel gear 13 with internal spline, large bevel gear 20, reduction box 16 and other qualities, m3 is the mass of the dynamic shock absorber, that is, the mass of the motor 1. By properly setting the damping coefficient C3 of the damping element of the dynamic shock absorber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com