Artificial quartz stone pressing system

An artificial quartz stone and vibration plate technology, applied in the field of quartz stone pressing, can solve the problems of low shock force conductivity, increase shock force, and it is difficult to ensure the uniformity of force on the vibration platform, so as to improve equipment life and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the technical scheme is further described as follows:

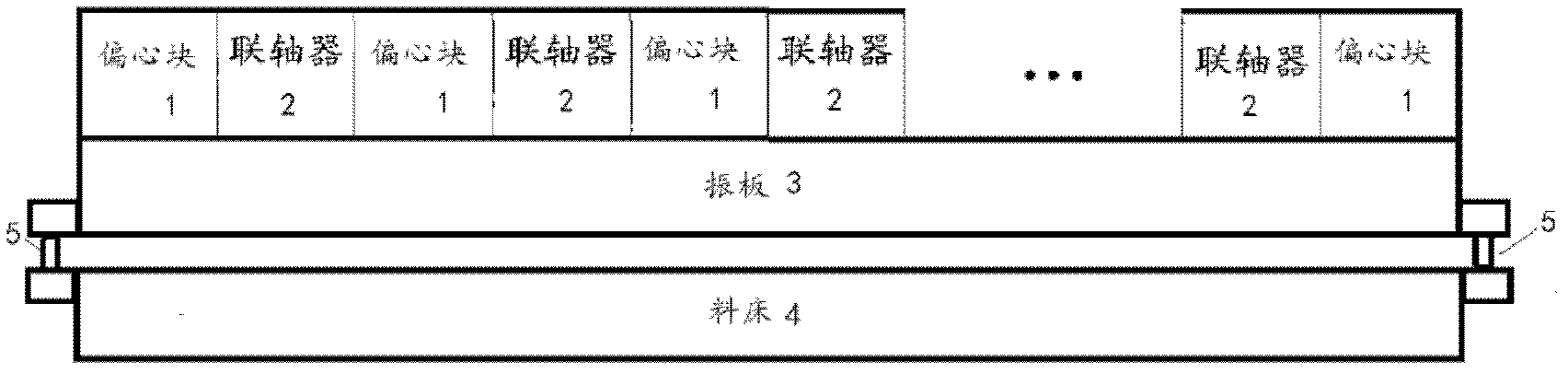

[0018] An artificial quartz stone pressing system includes a frame, a motor, an eccentric block, a vibrating plate and a material bed, the material bed is equipped with a mold; the vibrating plate and the material bed are connected to the frame; the eccentric block is connected to the rotating shaft, The rotating shaft is connected to the vibrating plate through a bearing, and the output shaft of the motor is connected to the rotating shaft; the vibrating plate is above the material bed, and the distance between the vibrating plate and the material bed corresponds to the thickness of the artificial quartz stone to be processed; The frame presses the vibrating plate through an oil cylinder or an air cylinder.

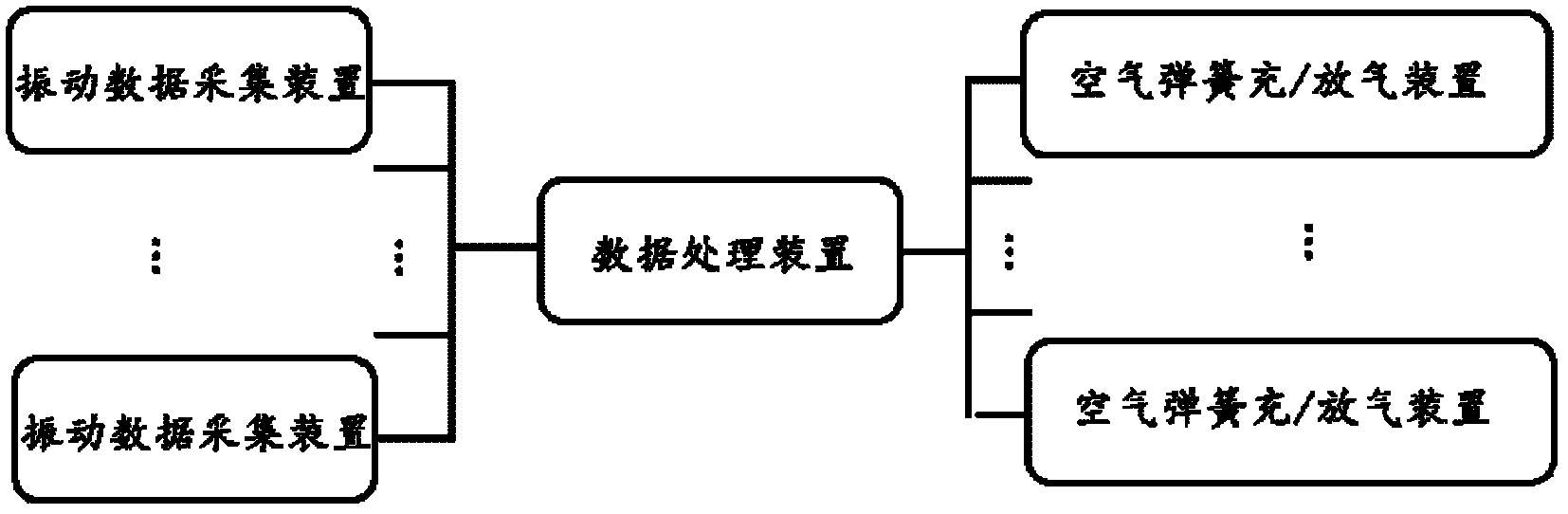

[0019] Between the vibration plate and the material bed, a plurality of air springs are arranged around the mold; the air springs are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com