Full-automatic closed-type steam saucepan

A closed and fully automatic technology, applied in application, food preparation, food science, etc., can solve the problems of high labor intensity, reduced production efficiency, poor sealing, etc., to reduce labor intensity, improve production efficiency, and prevent overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

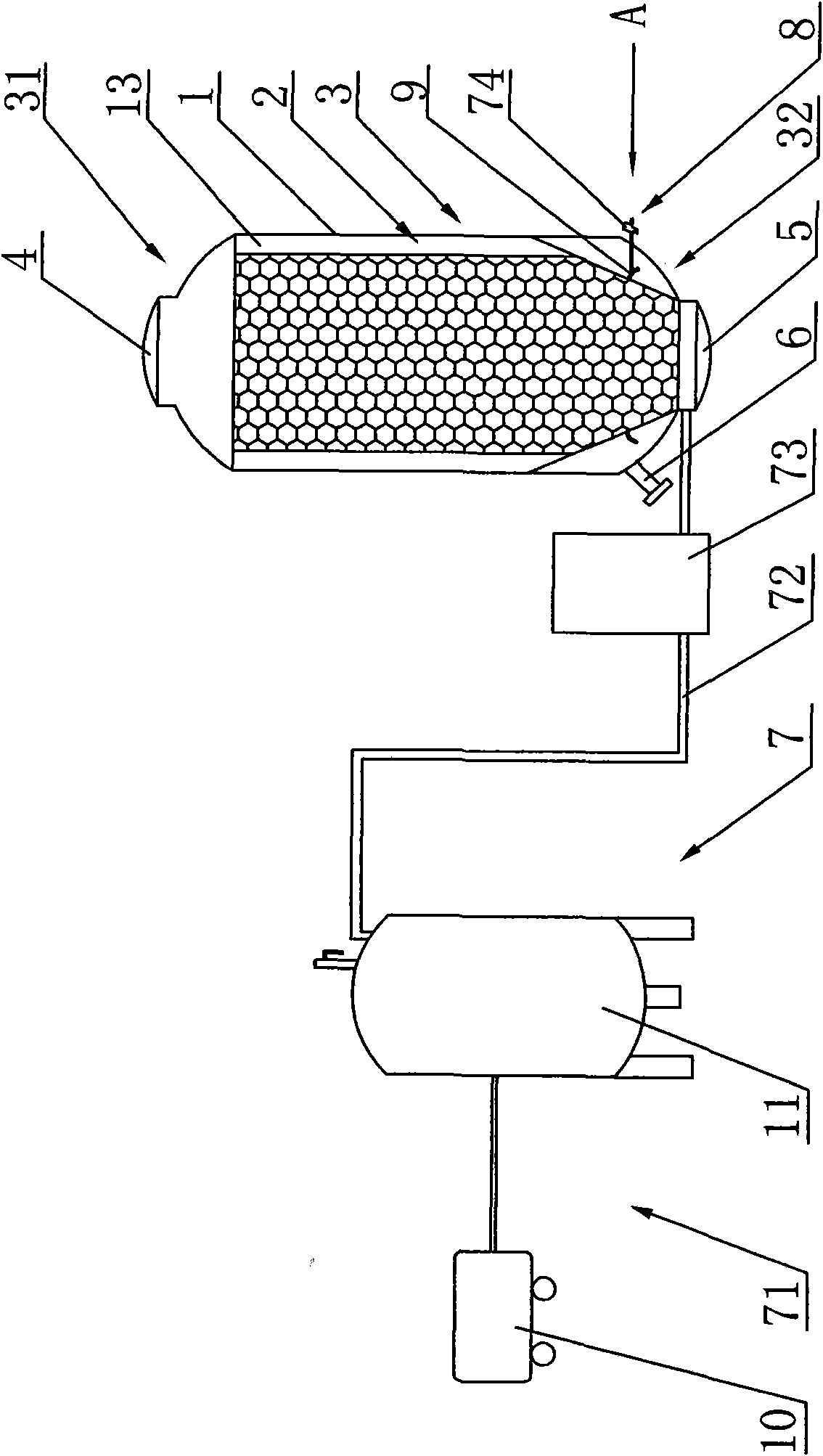

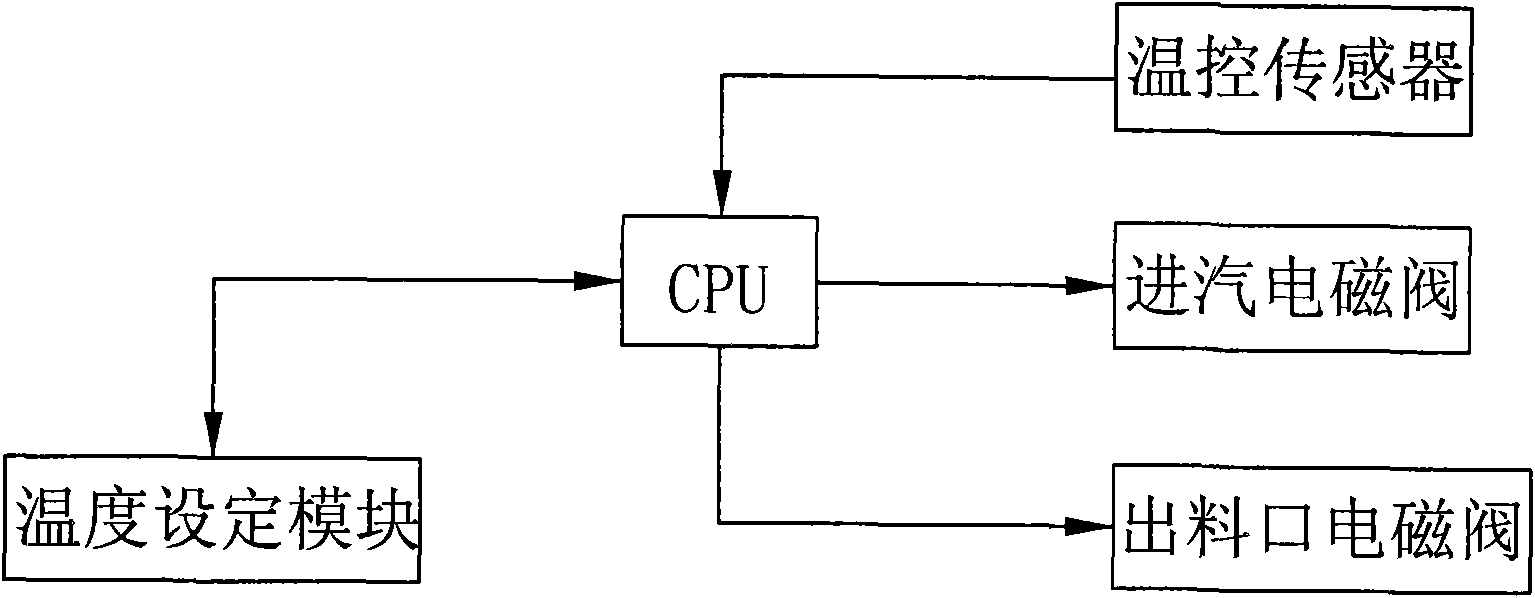

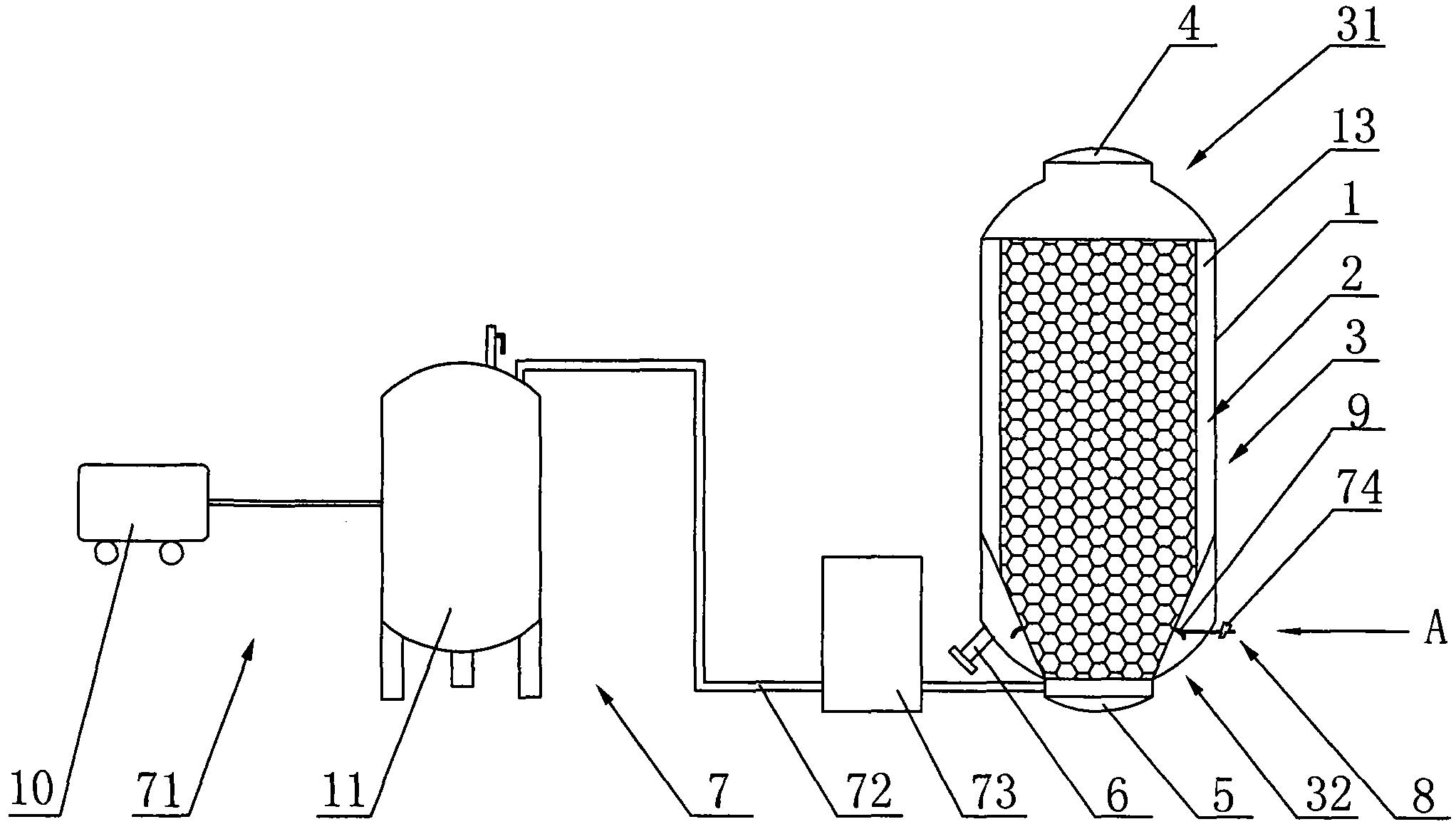

[0014] Such as figure 1 As shown, a fully automatic closed steam cooking pot includes a pot body 3 surrounded by a pot wall 1 with a closed heating chamber 2, and the top 31 and the bottom 32 of the pot body 3 are respectively provided with a closed heating chamber 2 The connected feed port 4 and discharge port 5 are provided with valves to control their opening and closing. The pot body is provided with a decompression port 6, which also includes an automatic control valve opening Closed automatic detection control device 7, the automatic detection control device 7 is connected with the valve, the automatic detection control device 7 is composed of a high-pressure gas source 71, a gas pipe 72 and a control box 73 with a CPU, a temperature control sensor, and a temperature setting module. The sensor, the temperature setting module, the steam in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com