Production method for boxed bean curd and boxed bean curd

A production method and boxed tofu technology are applied in the boxed tofu production method and boxed tofu field, which can solve the problems of high production cost, complex equipment, high energy consumption and economic pressure, and achieve equipment and floor space saving, quality improvement and income efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

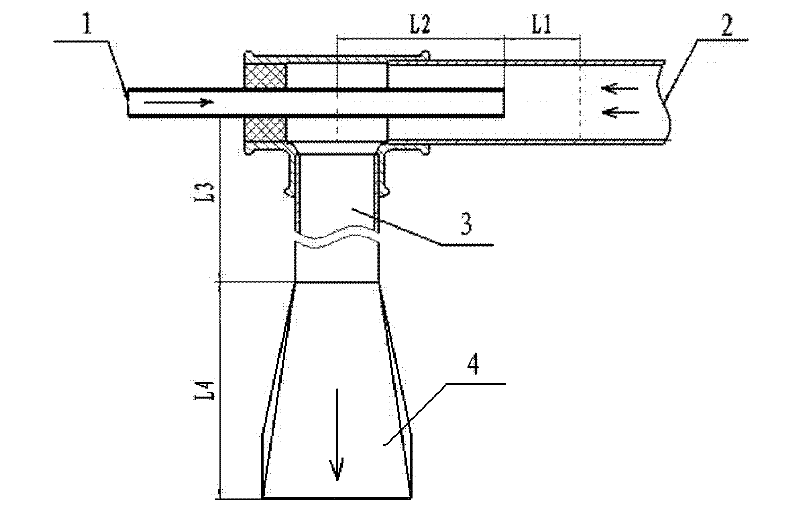

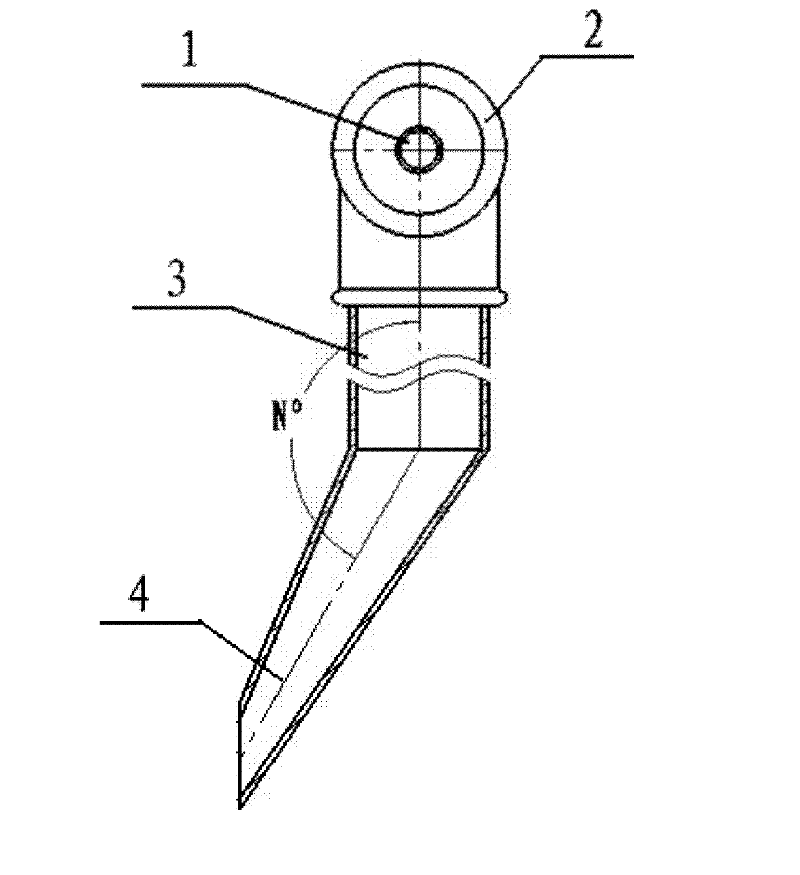

[0045] figure 1 It is the front view of the soya-bean milk-coagulant mixer that the embodiment of the present invention adopts; figure 2 for figure 1 left view of .

[0046] The soybean milk used in this example is boiled and matured according to a conventional method, and kept at 85-95° C. for mixing and coagulation with a coagulant.

[0047] Such as figure 1 and figure 2 As shown, the soya-bean milk-coagulant mixer used in this implementation has at least one coagulant delivery pipe 1, a soya-bean milk delivery pipe 2 with a pipe diameter larger than the coagulant delivery pipe 1 and one end closed, and a soya-bean milk delivery pipe 2 close to the closed end. The side wall is connected and the mixed slurry output pipe 3 that changes the flow direction of the material, the at least one coagulant delivery pipe 1 extends from the closed end of the soybean milk delivery pipe 2, and the coagulant delivery pipe 1 is connected to the soy milk delivery pipe 2 The protruding ...

Embodiment 2

[0061] The production method of the soybean milk used in this example is as follows: before pulping, the soybean raw material is crushed, and the germ and soybean skin are removed to obtain soybean cotyledon fragments. After crushing, the germ in soybeans can be removed by sieving, and the skin can be easily removed by winnowing. Soybean cotyledon fragments can be completed by conventional means in this field. For example, using a crusher to crush the raw beans requires only crushing the raw beans into appropriate fragments. In this embodiment, the soybeans are crushed into 4 to 6 petals (1 / 4-1 / 6 crushed cotyledon), at this time, it only takes 30-45 minutes to complete the water absorption process of soybean cotyledon crumbs, and the water absorption reaches 1.2-1.3 times of the weight of cotyledon crumbs, which is more conducive to meeting the pulping requirements.

[0062] Specifically, the crushed soybean cotyledons (1 / 4 to 1 / 6 grains) are soaked in tap water with a hardne...

Embodiment 3

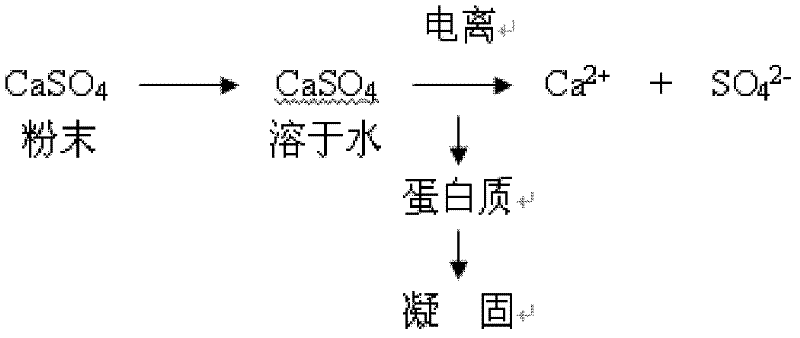

[0069] Adopt the soybean milk-coagulant mixer identical with embodiment one and the soybean milk identical with embodiment two, coagulant is the CaSO that mass percent is 10% 4 2H 2 O suspension. The storage tank is agitated with an electric stirrer to maintain the suspension state, and the coagulant is transported using an adjustable-speed gear pump (realizing that the pump pressure can be adjusted to 1.5Kg / cm 2 ).

[0070] Turn on the soymilk valve and gear pump, mix 85°C soymilk and coagulant in the soymilk-coagulant mixer, use five 400mL packaging containers to receive 350mL of the mixed solution, keep warm at 85°C for 20 minutes, cool naturally to room temperature, and pour gently out. All 5 cups of samples can maintain a complete cup shape without deformation within 1 hour, and the precipitated water after 12 hours accounts for 10-12% of the total weight of tofu. The hardness and elasticity of the tofu prepared in this example are better than those of the commerciall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com