Synchronization control device of deceleration direct-current motor

A DC motor, synchronous control technology, applied in the direction of DC motor speed/torque control, control of multiple DC motors, excitation or armature current control, etc. , to achieve the effect of improving the speed control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

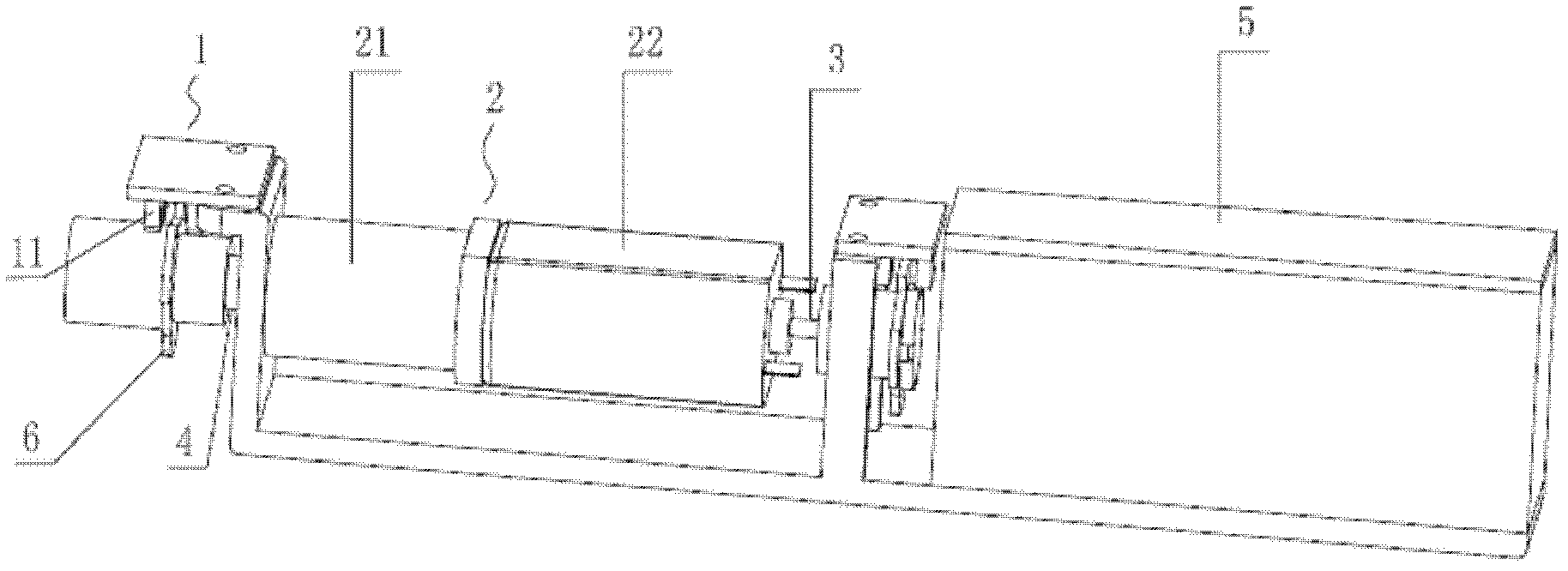

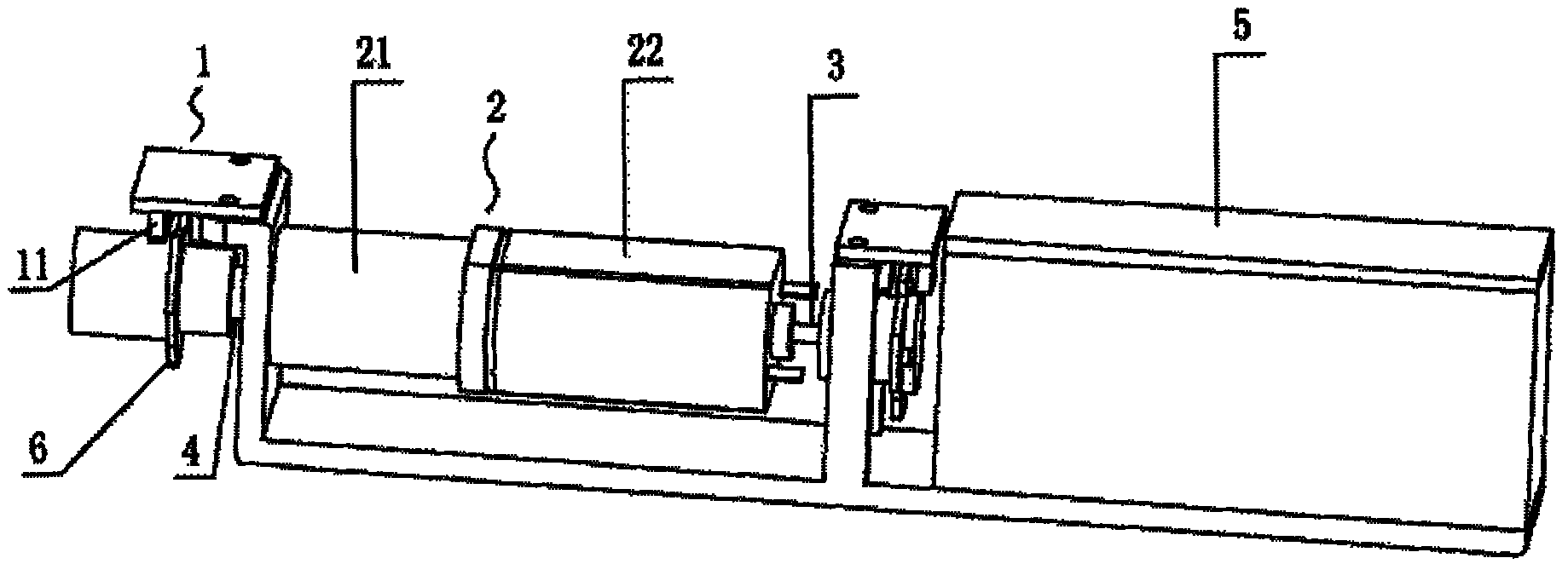

[0018] Referring to accompanying drawing below, the present invention will be further described:

[0019] see figure 1 , the synchronous control device of the deceleration DC motor of the present invention comprises a deceleration DC motor 2 and a controller 5, the deceleration DC motor 2 includes a motor main body 22 and a reduction box 21, and the deceleration DC motor 2 is provided with a device for monitoring The speed measurement module 1 of the current speed of the motor shaft, the controller 5 is provided with a storage unit for storing the reference speed of the motor shaft, the speed measurement module 1 is connected to the controller 5, when the current speed of the deceleration DC motor 2 is different from the reference speed At the same time, the controller 5 changes the input voltage of the deceleration DC motor 2 . In this embodiment, the speed measurement module 1 includes an opaque fan blade 6 arranged on the motor shaft and a detection unit for detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com