rectifier motor

A technology of electric motors and rectifiers, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of reduced service life and large tolerances of robustness, and achieve the effect of small tolerances, simple methods and methods, and more robust guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

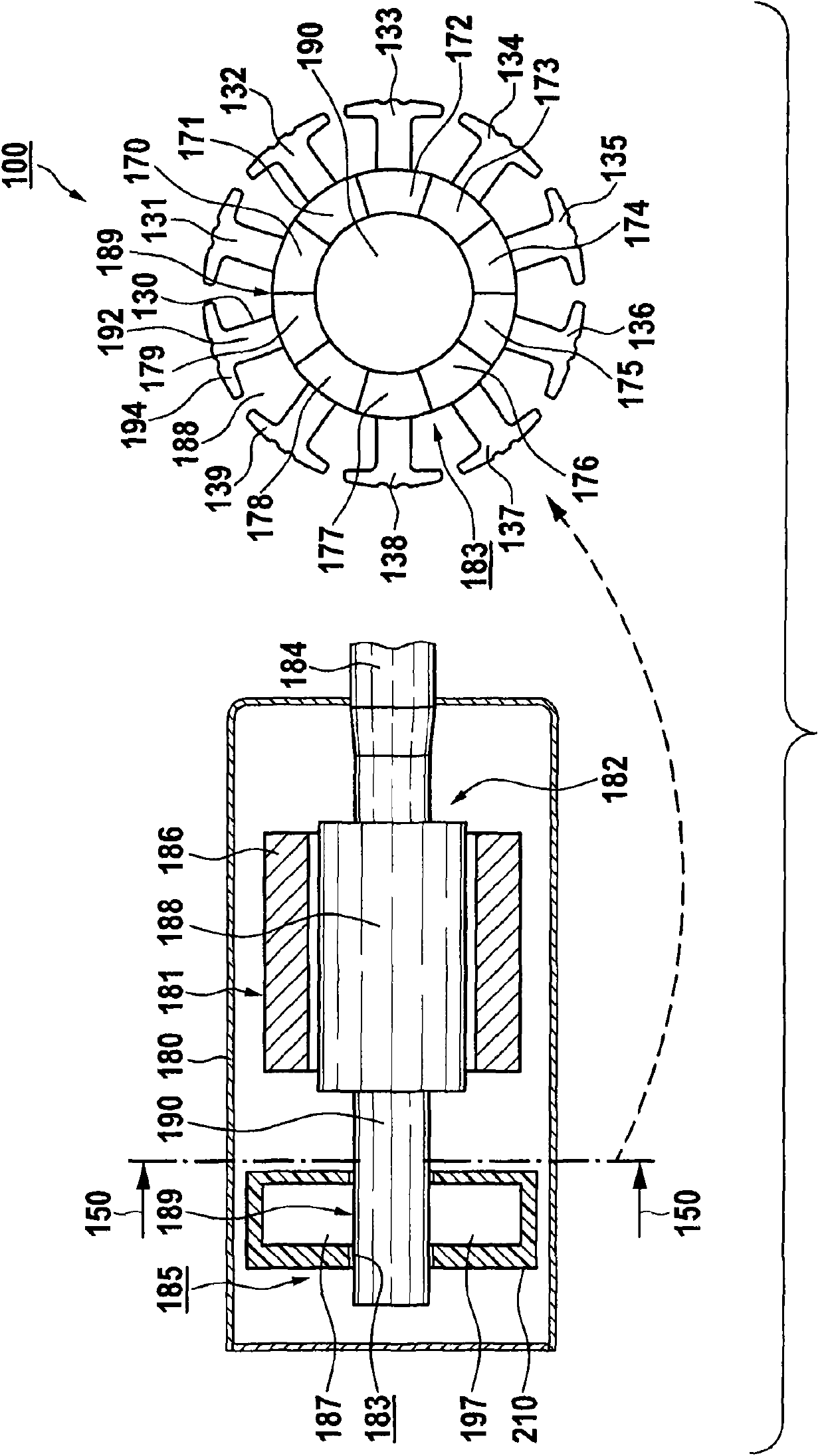

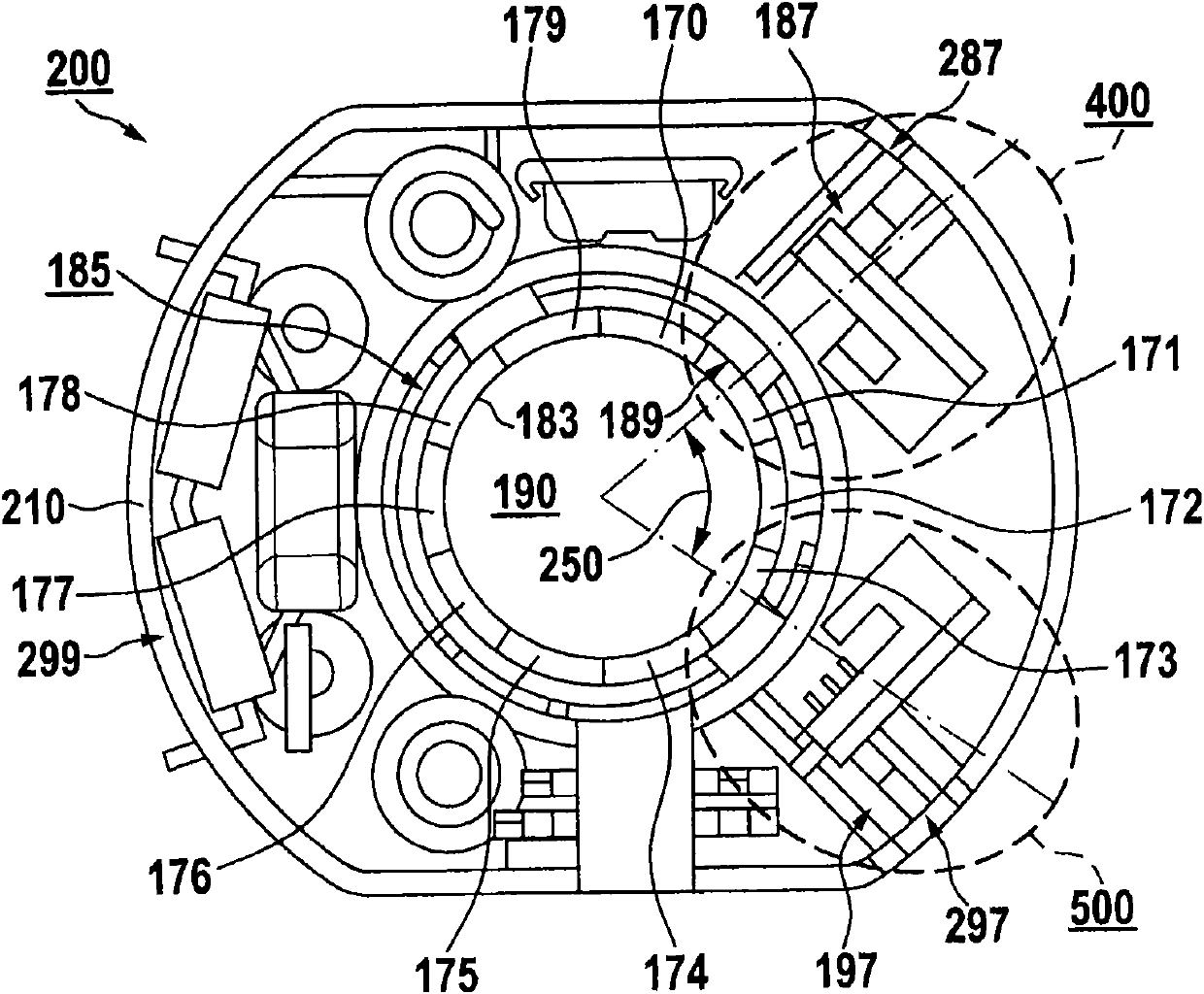

[0054] figure 1 Shown is a commutator motor 100 according to one embodiment with stator and rotor parts 181 and 182 , which has a motor shaft 184 which is exemplarily mounted in a motor housing 180 and which can, for example, be Used, for example, as drive shafts for electric window regulators in automobiles. The stator part 181 has, for example, permanent magnets 186 , and the rotor part 182 has, for example, a rotor core or iron core 188 .

[0055] Commutator motor 100 has a commutator 185 with a defined commutator diameter for commutation, which can be controlled or regulated so that not only reverse rotation but also a desired speed can be specified. The working principle and structure of a suitable commutator motor can be fully understood from the prior art, so no further elaboration will be made here for the sake of brevity.

[0056]The rectifier 185 exemplarily includes a current collector 183 which forms sliding contact with two or more brushes 187, 197 on an associa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com