Method for forming silicon on insulator-SiGe heterojunction 1T-DRAM (1T-Dynamic Random Access Memory) structure on insulator and formed structure

A 1T-DRAM and insulator technology, applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as transistor threshold voltage reduction, achieve lower operating voltage, increase output current balance, and increase signal margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

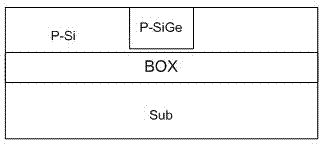

[0036] The present invention provides a carbon silicon-germanium silicon heterojunction 1T-DRAM structure, comprising: a semiconductor substrate, a buried oxide layer, the buried oxide layer covers the semiconductor substrate; a P-type silicon layer, the P A type silicon layer is covered on the buried oxide layer, and the NMOS devices separated by STI are arranged on the P-type silicon layer, wherein the channel in the NMOS device is P-type SiGe, and the source region in the NMOS device for N + -SiC, N drain region + -SiGe.

[0037] The present invention will be further described below through the examples, so that the content of the present invention can be better understood, but the following examples do not limit the protection scope of the present invention.

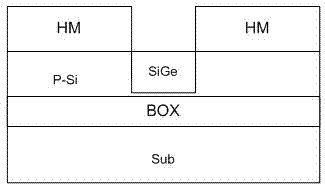

[0038] The silicon-on-insulator silicon-germanium heterojunction 1T-DRAM structure provided by the present invention is formed by the following method.

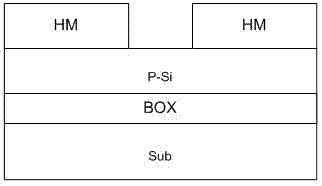

[0039] A hard mask layer is deposited on the formed SOI waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com