System for monitoring ingredient change of insulating oil of transformer

A transformer insulating oil and insulating oil technology, applied in the field of sensors, can solve the problems of failing to propose a good solution, not being able to monitor the transformer insulating oil, and adding different substances, and achieve long effective use time, small size, and simple use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

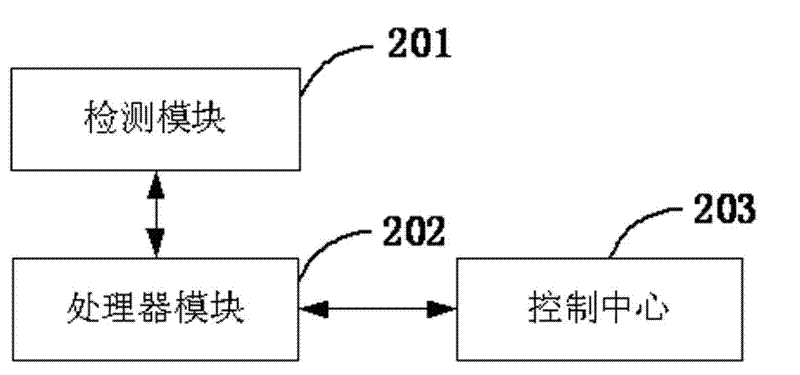

[0035] It should be noted that in the patent of the present invention, the system for monitoring the composition change of the transformer insulating oil is not aimed at the detection of gas in the transformer insulating oil, but the direct detection of the liquid composition of the transformer insulating oil. detection of antioxidants, acids, water or other polar molecules in the

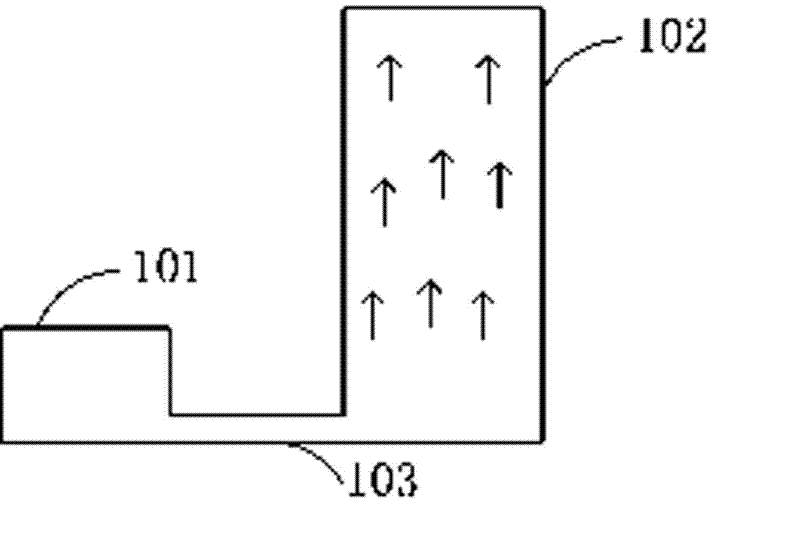

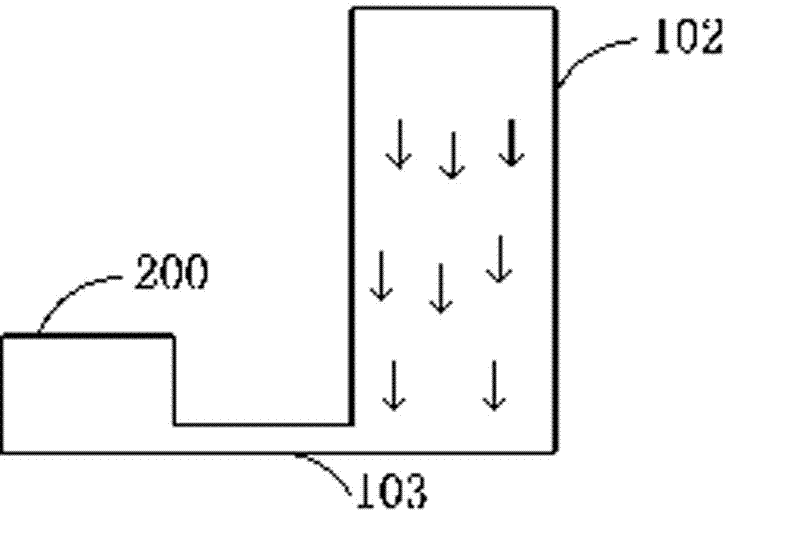

[0036] figure 2 It is the monitoring application diagram of the system in the embodiment of the present invention, such as figure 2 As shown, the monitoring system 200 of the present invention is connected to the bottom of the insulating oil tank 102 through the oil pipe 103 , and the monitoring system 200 monitors the liquid composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com