Temperature measurement and calibration platform in space vacuum environment

A vacuum environment, temperature measurement technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems of small number of gas molecules, less involved, unfavorable experimental measurement and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

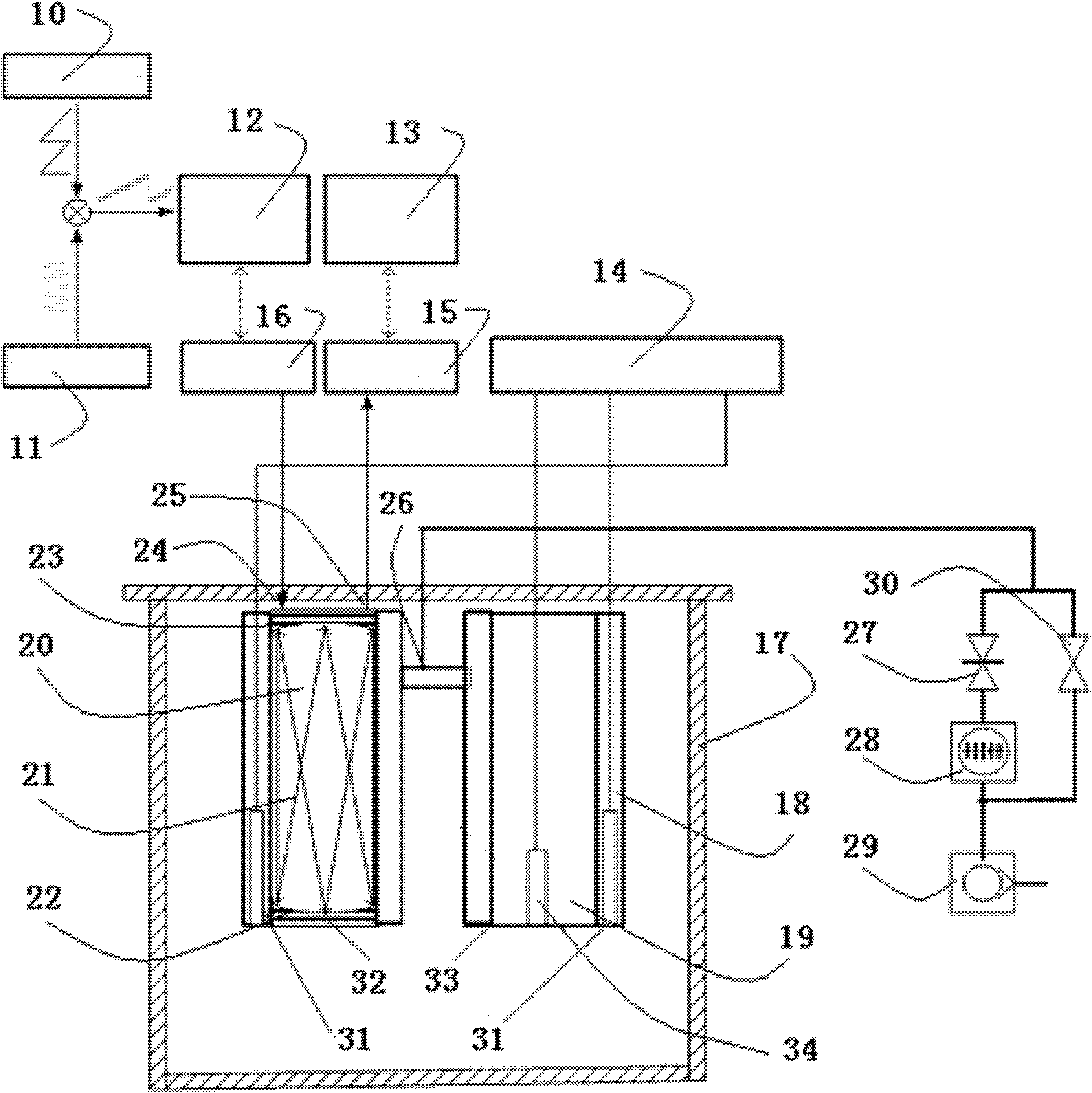

[0019] Below in conjunction with the attached drawings ( figure 1 ) Describe the present invention.

[0020] figure 1 It is a schematic diagram of the structure of the temperature measurement and calibration platform in the space vacuum environment of the present invention. Such as figure 1 As shown, the temperature measurement and calibration platform in a space vacuum environment includes a thermostatic bath 17 in which is provided a twin vacuum chamber (that is, the vacuum chamber 20 and the second vacuum chamber of the first vacuum chamber connected by a tee 26) 2 Vacuum chamber 19) of the vacuum chamber, the twin vacuum chambers include a first vacuum chamber 32 and a second vacuum chamber 33, and the first vacuum chamber 32 and the second vacuum chamber 33 are connected by a tee 26 In a vacuum extraction device, a standard thermometer sensor 31 is provided on the outer wall of the first vacuum chamber 32 and the outer wall of the second vacuum chamber 33, and the standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com