Method for measuring diameter of high-temperature steel pipe by using image recognition technology

A technology of technical measurement and image recognition, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of extended construction period, high cost, waste of raw materials, etc., and achieve the effect of improving enterprise efficiency, reducing material costs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

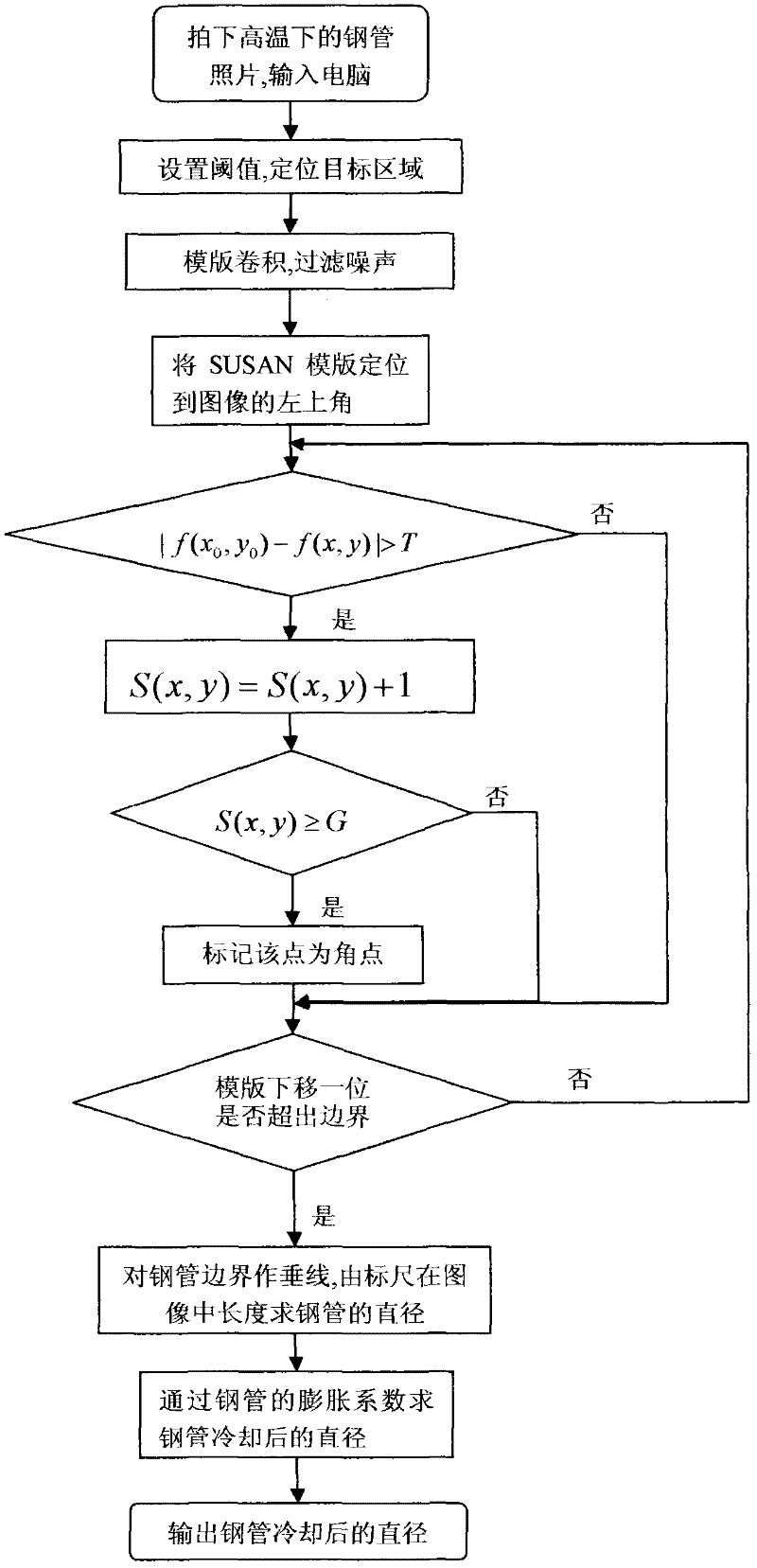

[0040] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

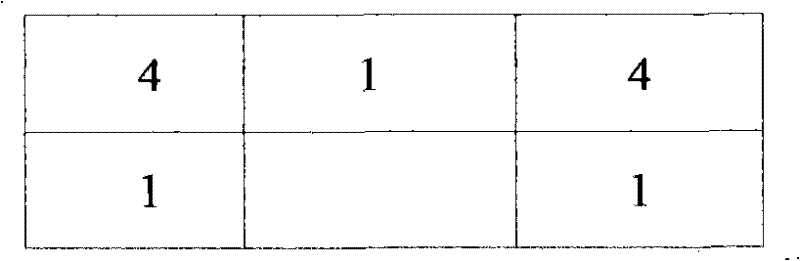

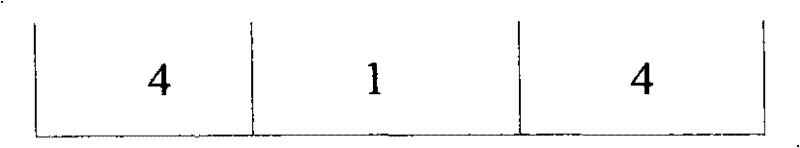

[0041] The original measurement system was improved by using a high-temperature-resistant metal ruler, a high-definition camera and a PC. By acquiring the photos of the high-temperature steel pipe and processing the PC as follows: using the grayscale threshold to extract the The part of the high-temperature steel pipe in the image, and then use Gaussian filtering to filter and enhance the image, and then use the SUSAN operator to extract the steel pipe boundary (and its direction) in the image, make a vertical line of the boundary, and then use the measured high-temperature resistant ruler. Calculate the ratio, and finally get the radial length of the steel pipe in the image. Satisfactory results have been obtained through the measurement with traditional measuring tools, and the error is within 0.1mm, so the work efficiency is improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com