Tin melting furnace

A technology for melting tin and furnace body, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of low temperature control accuracy, unstable welding quality, inaccurate temperature values, etc., to achieve easy maintenance, improve welding quality, increase Effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

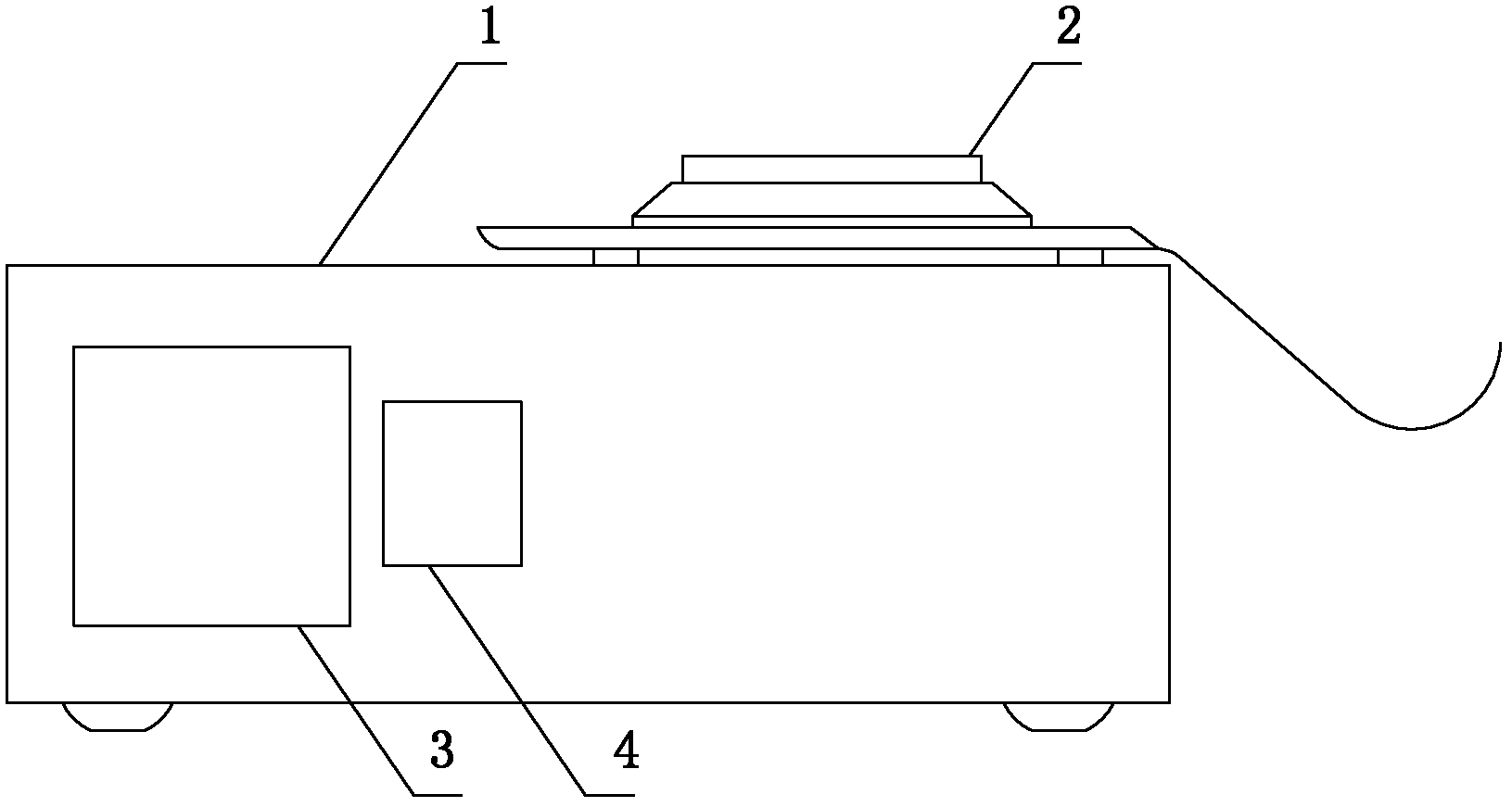

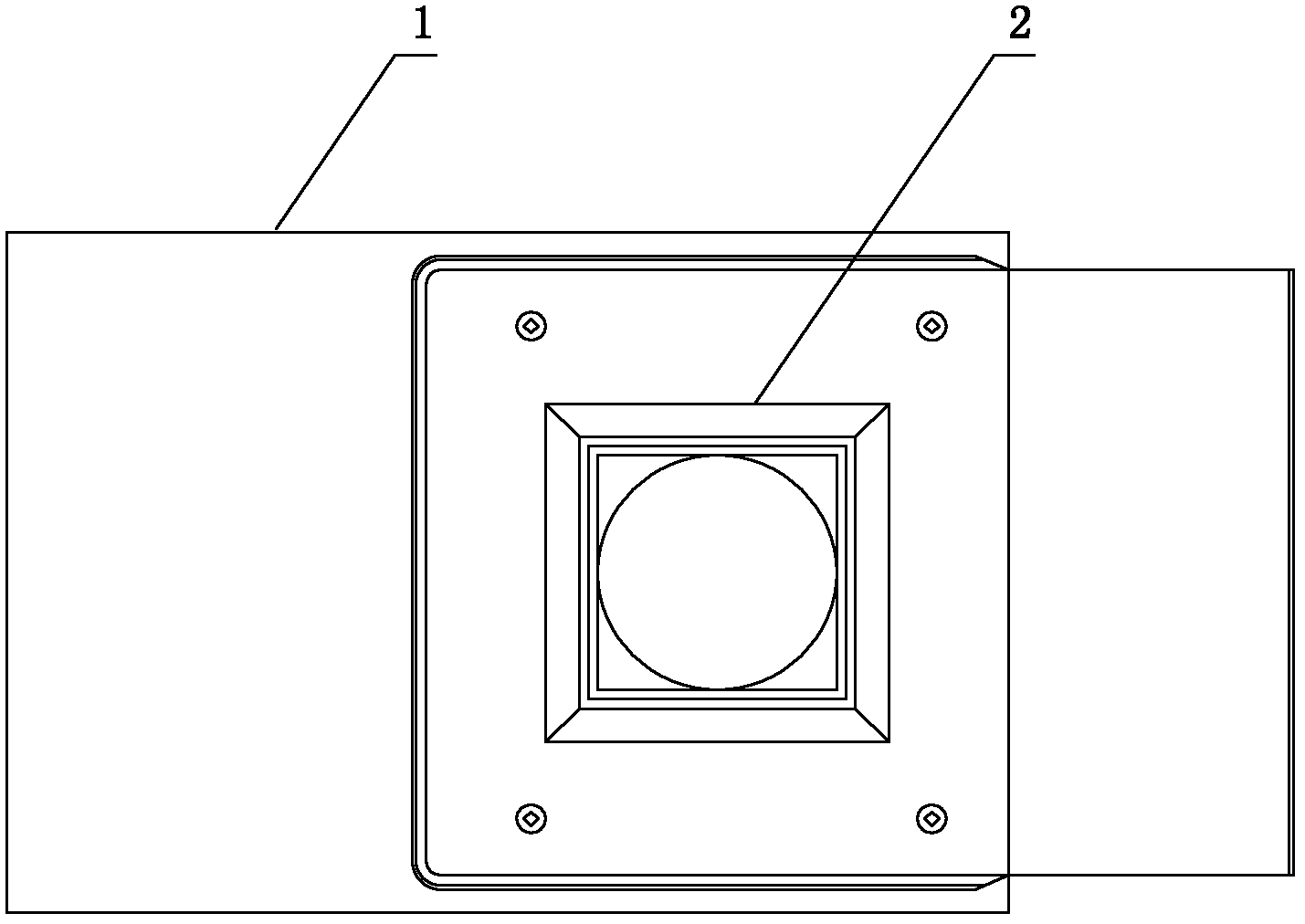

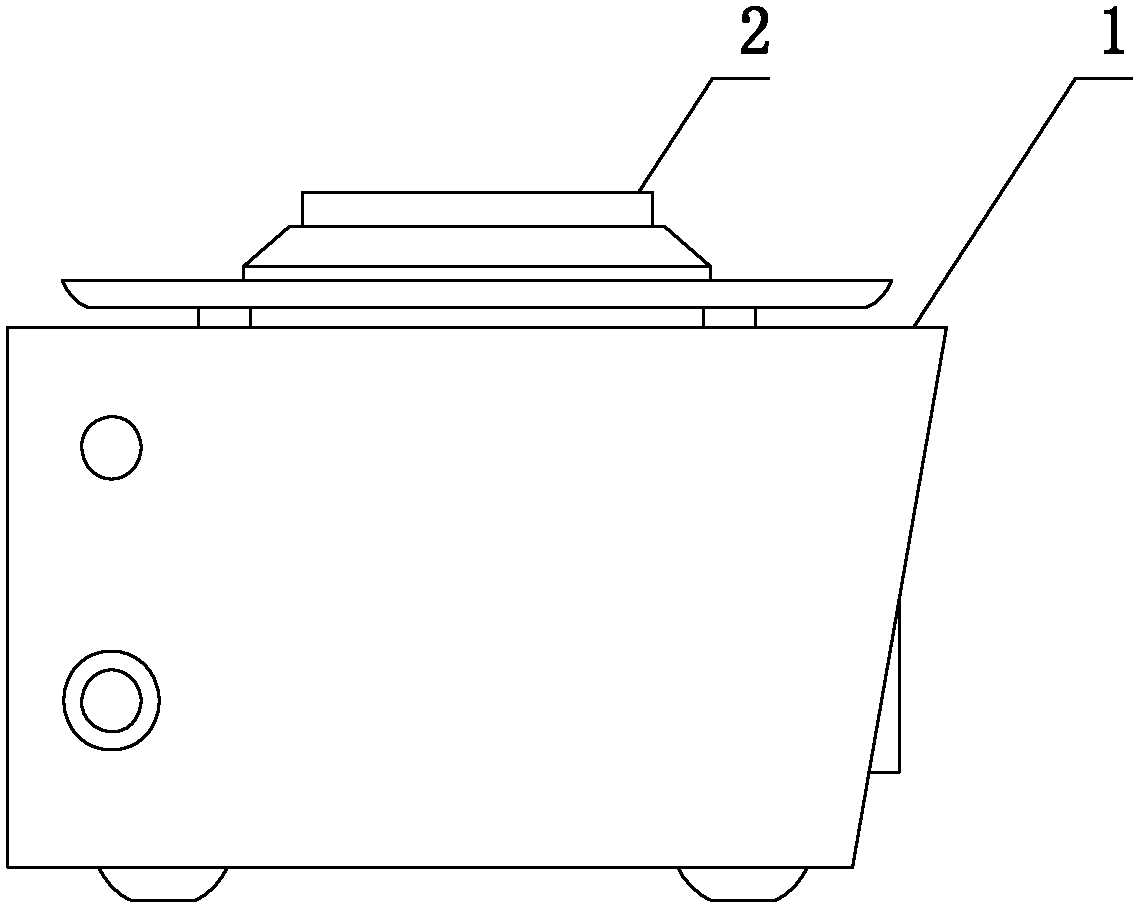

[0024] See Figure 1 to Figure 6 , a tin-melting furnace, comprising a furnace body 1, a tin-melting tank 2 arranged in the furnace body, a heating pipe, a temperature sensor and a temperature control circuit, the tin-melting tank 2 is a ceramic tin-melting tank, and the ceramic tin-melting tank The tank can be a 95 porcelain melting tin tank; the bottom of the tin melting tank 2 is horizontally provided with a plurality of side-by-side through holes 5, one of the through holes 5 is the hole for placing the temperature sensor, and the other through holes 5 are The heating tube placement hole, the number of the through holes 5 can be an odd number, and the central through hole 5 can be the temperature sensor placement hole; the bottom inner su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com