Chimney with spiral flow guide plate on outer wall

A deflector and spiral technology, applied in the field of chimneys, can solve the problems of excessive chimney height-to-diameter ratio, low bending strength, and lateral displacement, so as to reduce lateral displacement and deformation, improve resistance to deformation, and enhance resistance to deformation. The effect of bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

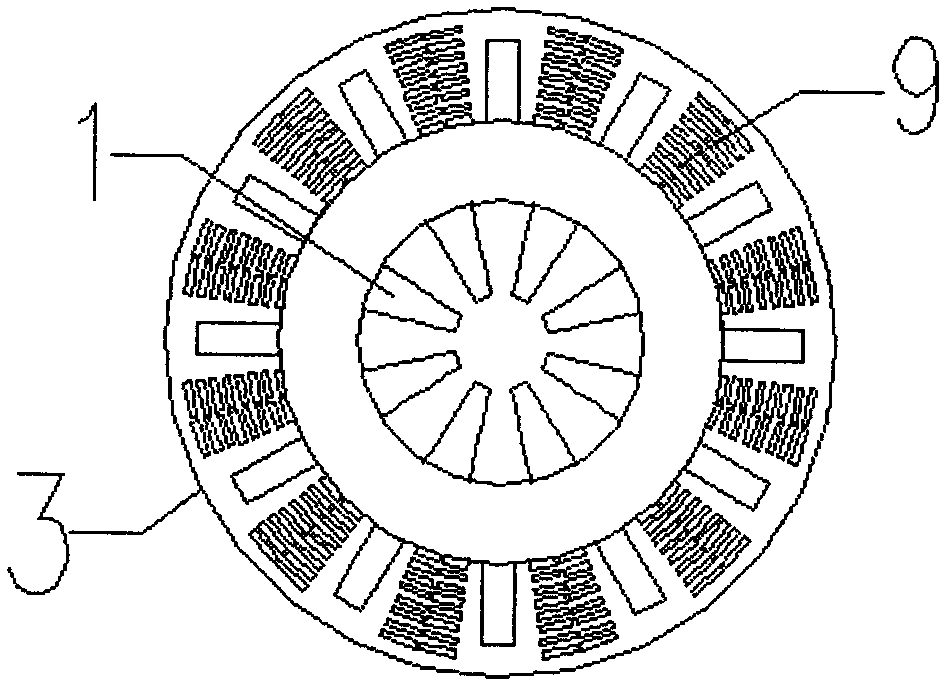

[0024] Embodiment 1: A chimney with a spiral deflector on the outer wall, including a dust collector 1, a guardrail 2, a workbench 3, a rib 4, a chimney body 5, a deflector 6, a connecting flange 7, and a flange rib 8. Ventilation grid 9. The dust collector 1 is installed on the top of the chimney body 5 and connected with the chimney body 5. The chimney body 5 is formed by connecting several chimneys with connecting flanges 7. 3, the rib plate 4 is used to weld it to the chimney body 5, and the guardrail 2 is welded to the outer edge of the workbench 3. There is a ventilation grid 9, and the deflector 6 is continuously and uniformly welded on the outer wall of the chimney body 5, and it surrounds the outer wall of the chimney body 5 from the bottom to the bottom of the top workbench 3. Flange ribs 8 are welded between the body 5, and the connecting flange 7 is fixed by bolt connection.

[0025] The diameter of the chimney body is 1m, and the length of each chimney body is 1...

Embodiment 2

[0027] Embodiment 2: The composition structure is the same as that of Example 1.

[0028] Chimney diameter D 2 =1.5m, the length L=15m of every chimney body 5. Deflector 6 pitch P=0.5m, width B 2 =0.35m, helix angle α=45°.

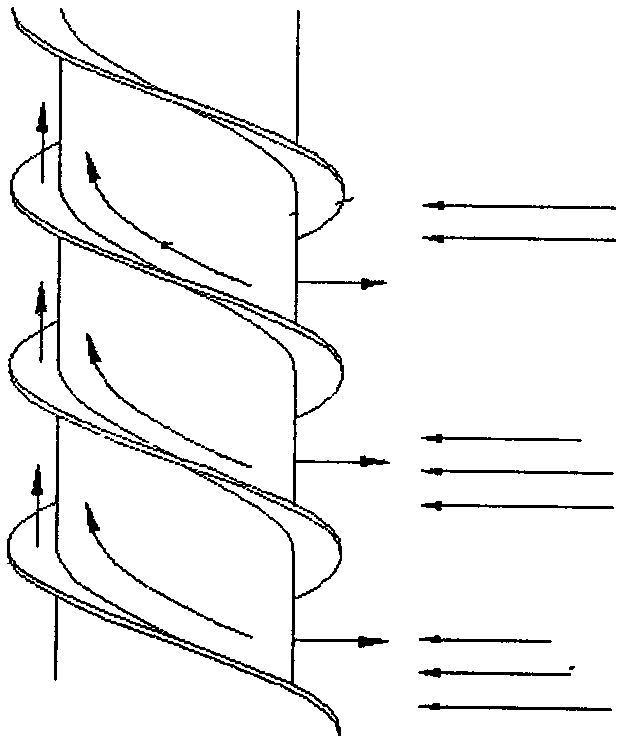

[0029]Carry out the diversion principle analysis to embodiment 2, the wind load vertically blows to the chimney body to the right, part of the air flow spirals up along the deflector 6 to the right, forming an upward airflow along the deflector 6, and part of the air flows along the deflector 6 Turn around the chimney body 5 during the left-hand helical ascending process to form a leftward turning airflow. The airflow rises along the deflector 6 and flows out from the top of the workbench 3 through the ventilation grid 9, converting the lateral load into a longitudinal load and reducing the pressure of the wind load on the chimney body 5; The direction of the wind load of the chimney body 5 flows out in the opposite direction, thereby resisting and off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com