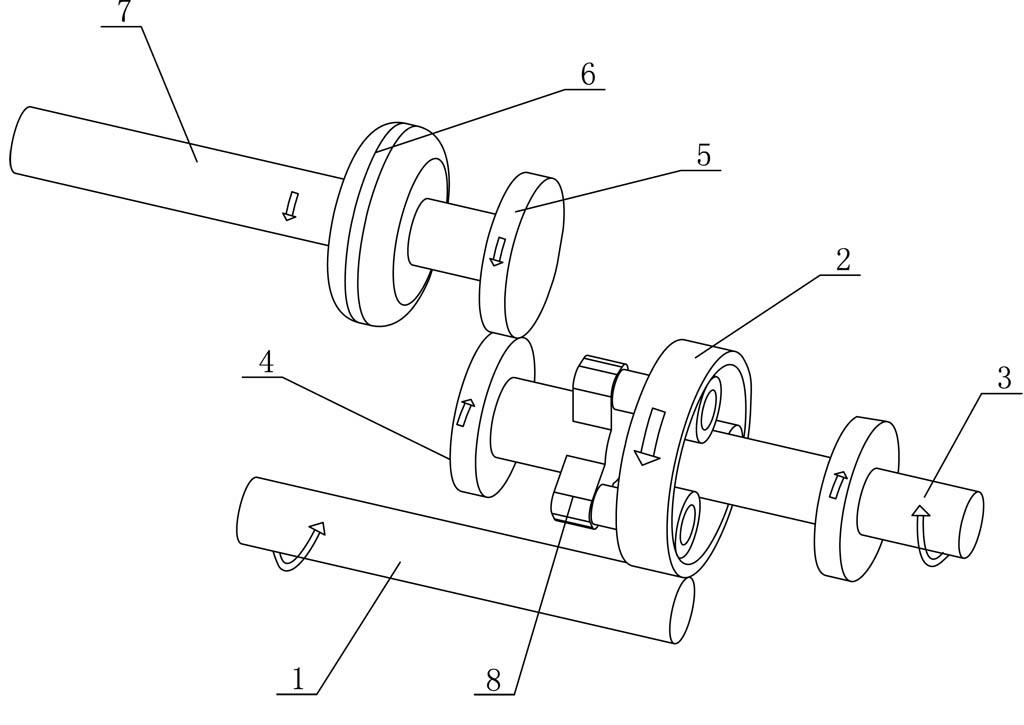

Stepless speed change structure for planetary gears

A planetary gear, continuously variable speed technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the high requirements of parts processing and lubrication, poor overload and impact resistance, and small speed change range, etc. problem, to achieve the effect of low manufacturing cost, large speed change range, and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

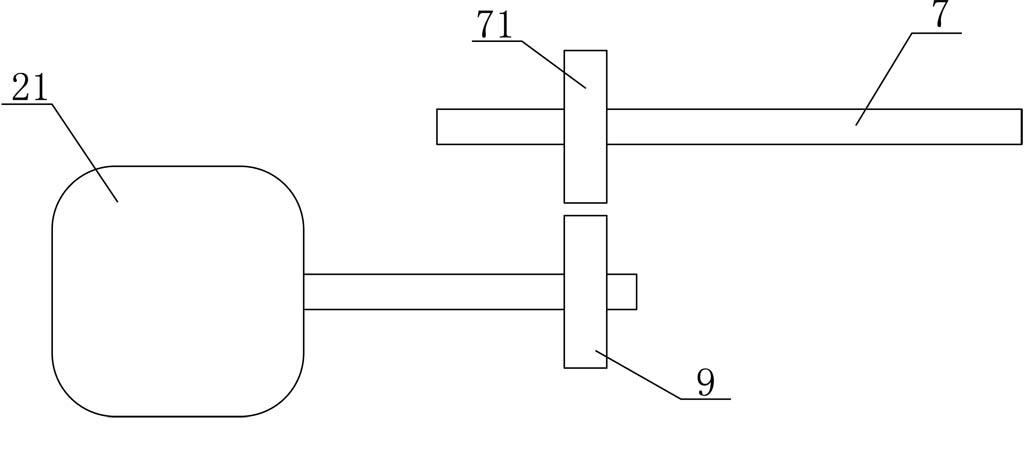

[0035] like figure 2 As shown, the power adjustment control device also includes a control motor 21 and an adjustment gear 71 installed on the control power input shaft 7. The control motor 21 includes a motor shaft 22 and a gear 9. The motor gear 23 is connected to the control power input shaft 7. The adjusting gear 71 on the input shaft 7 is connected. In this embodiment, the motor is used as the power source, and the speed of the control shaft is changed by changing the variable speed of the motor. The control motor 21 is connected with the core control unit on the automobile. Its principle is that the power source of the control power input shaft is provided by the motor, and the stepless speed change of the motor realizes the stepless speed change of the planetary gear.

Embodiment 2

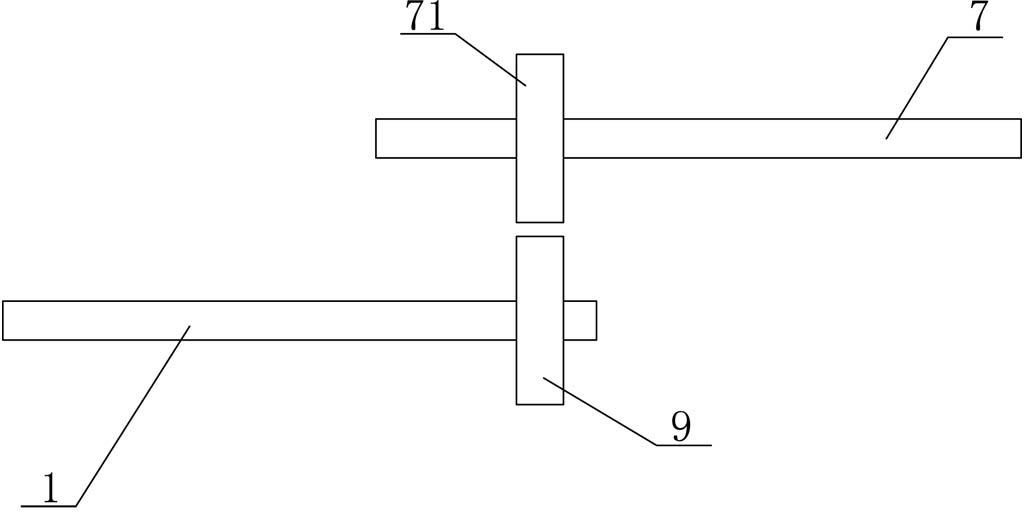

[0037] like image 3As shown, the power adjustment control device also includes a gear 9 installed on the power input shaft 1 of the automobile engine and an adjustment gear 71 installed on the control power input shaft 7 , and the gear 9 is connected to the adjustment gear 71 . In this embodiment, the power input shaft of the engine is used as the power source, and when the engine speed changes, the speed of the control shaft also changes accordingly. Its principle is that the power to control the power input shaft comes from the engine, and the change of the engine speed drives the change of the planetary gear speed.

Embodiment 3

[0039] like Figure 4 As shown, the power adjustment control device also includes a gear 9 installed on the power output shaft 12 of the automobile engine and an adjustment gear 71 installed on the control power input shaft 7 , and the gear 9 is connected to the adjustment gear 71 . In this embodiment, the power output shaft of the engine is used as the power source, and the speed of the control shaft is changed when the vehicle speed changes. Its principle is to control the power of the power input shaft from the output shaft (that is, related to the speed of the vehicle).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com