Composite ground heating floor

A floor and floor heating technology, applied in the field of building decoration materials, can solve the problems of complex manufacturing process and installation, low heat conduction efficiency, short heat conduction path, etc., and achieve the effect of short heat conduction path, high heat conduction efficiency, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

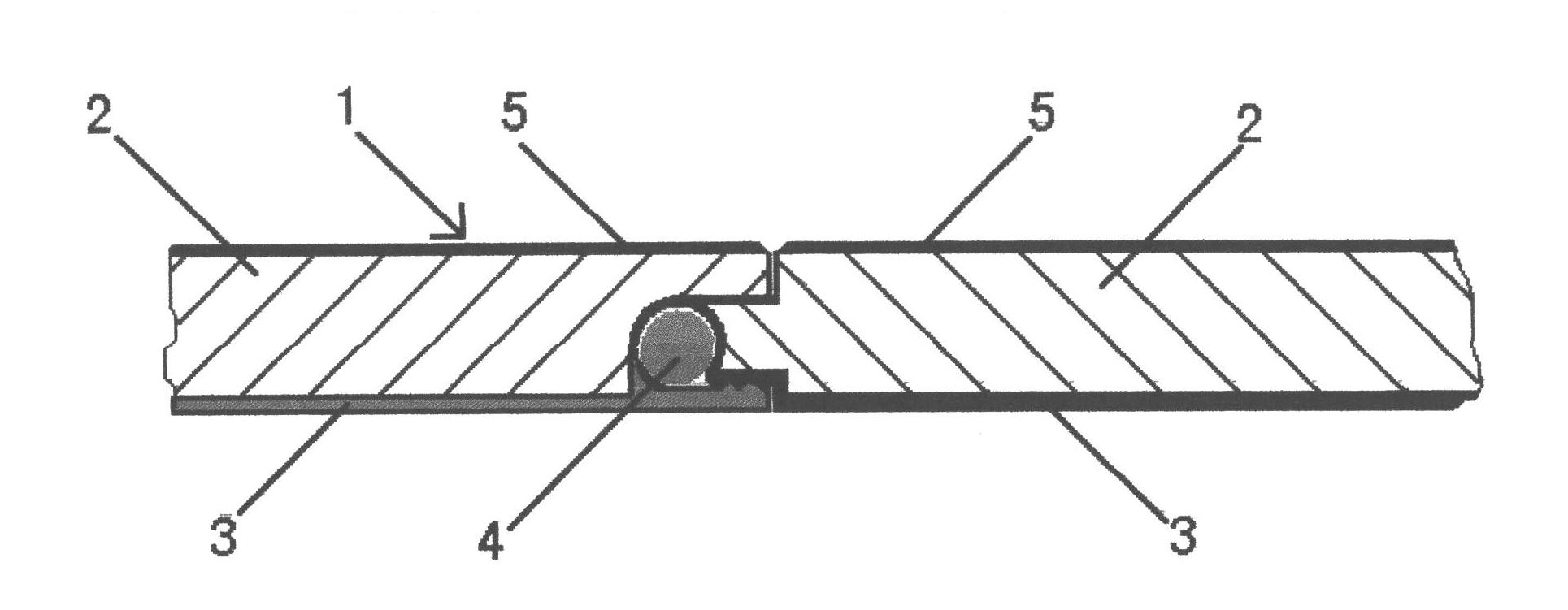

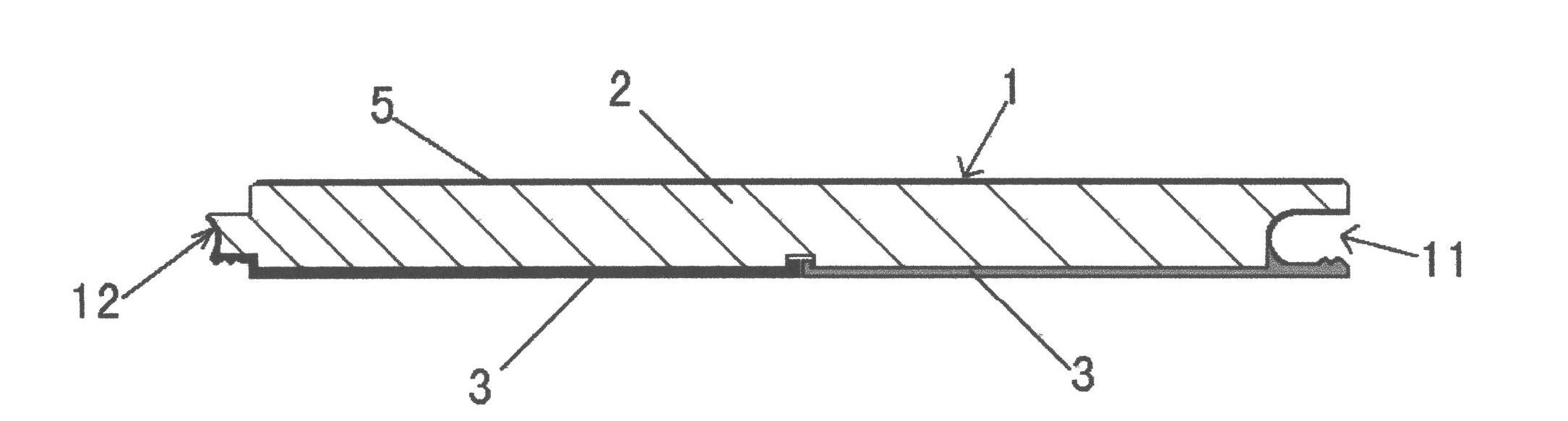

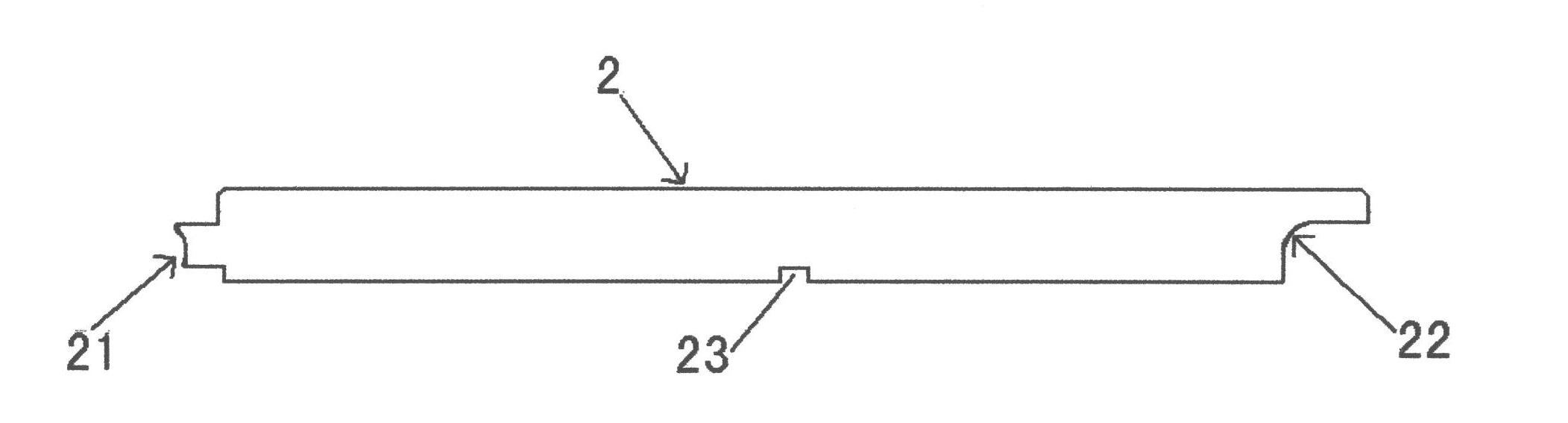

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a composite floor heating floor includes a floor body 1. The floor body 1 includes a base plate 2 and a heat conduction medium layer 3 compounded on the lower surface of the base plate 2. Bonding is achieved; the substrate 2 is a multilayer solid wood composite material and the upper surface of the substrate 2 is provided with a decorative surface 5, and the decorative surface 5 of the present embodiment is a wear-resistant paint layer; one side of the substrate 2 is provided with a first connection structure 21, The other side of the substrate 2 is provided with a second connection structure 22, and the heat conduction medium layer 3 includes a heat conduction portion 30 located on the lower surface of the substrate 2 and a heat conduction portion 30 arranged on both sides of the heat conduction portion 30 and respectively located at the first connection structure 21 and the second connection stru...

Embodiment 2

[0026] Embodiment 2: as figure 1 , Figure 5 and Figure 6As shown, a composite floor heating floor includes a floor body 1. The floor body 1 includes a base plate 2 and a heat conduction medium layer 3 compounded on the lower surface of the base plate 2. To achieve bonding, the bottom surface of the thermally conductive medium layer 3 of this embodiment is pasted with a decorative layer 6, and the decorative layer 6 of this embodiment is an aluminum foil reflective film; the substrate 2 is a multi-layer solid wood composite material and the upper surface of the substrate 2 is provided with a decorative surface layer 5. The decorative surface layer 5 of this embodiment is a wear-resistant paint layer; one side of the substrate 2 is provided with a first connection structure 21, and the other side of the substrate 2 is provided with a second connection structure 22. The heat conducting part 30 on the lower surface and the first heat receiving part 31 and the second heat recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com