Full flat type balance vertical ship lift adaptive to ship reception chamber outlet-inlet water

A technology for a vertical ship lift and a ship-carrying box, applied in the field of ship lifts, can solve problems such as unreasonable technology and poor economy, and achieve the effects of balancing weight, saving lifting driving power, and reducing construction costs and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

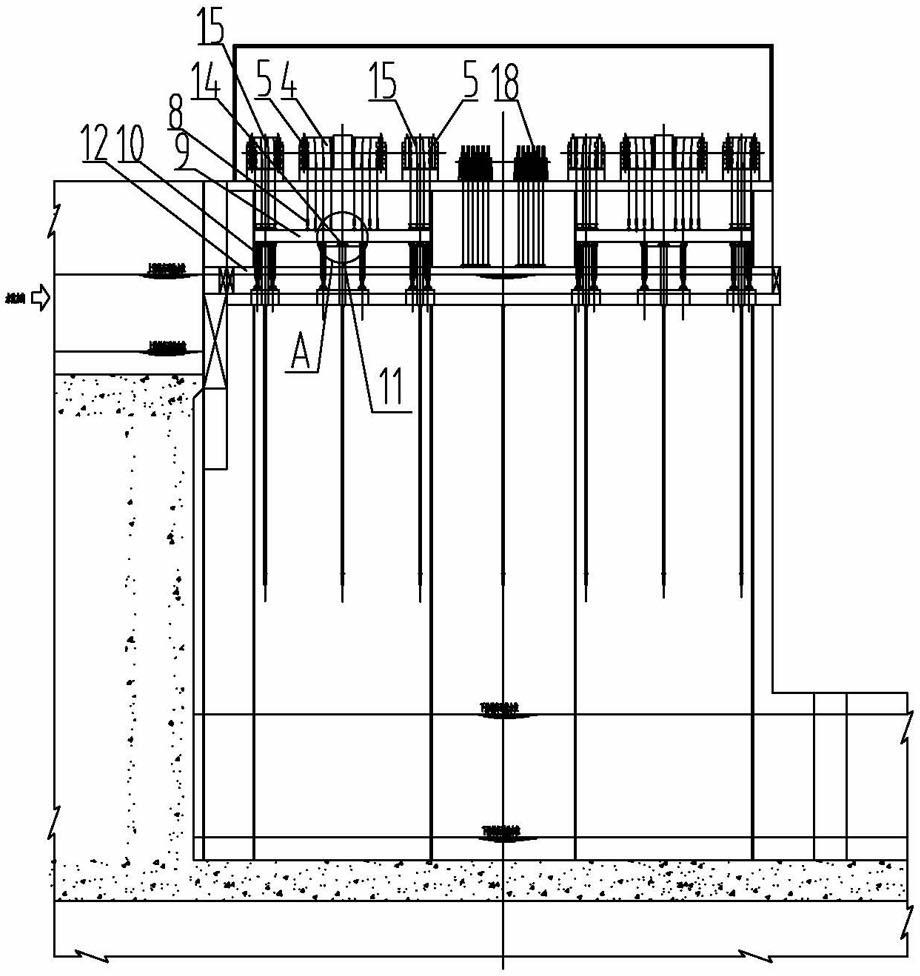

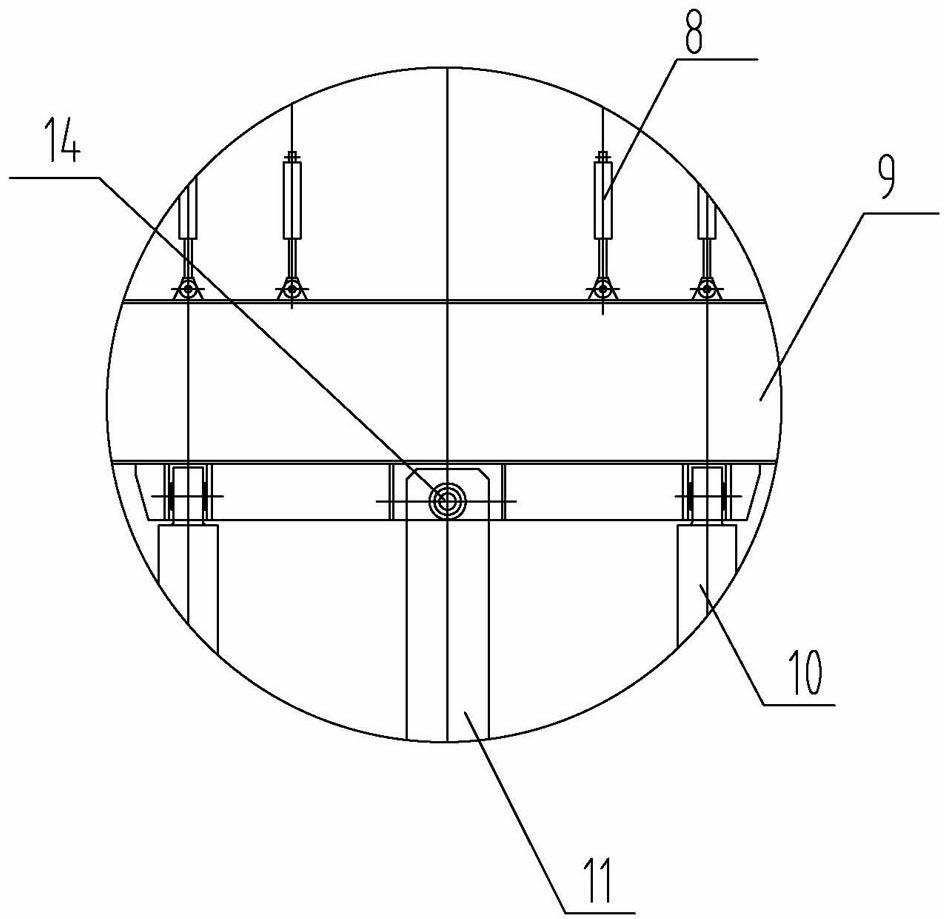

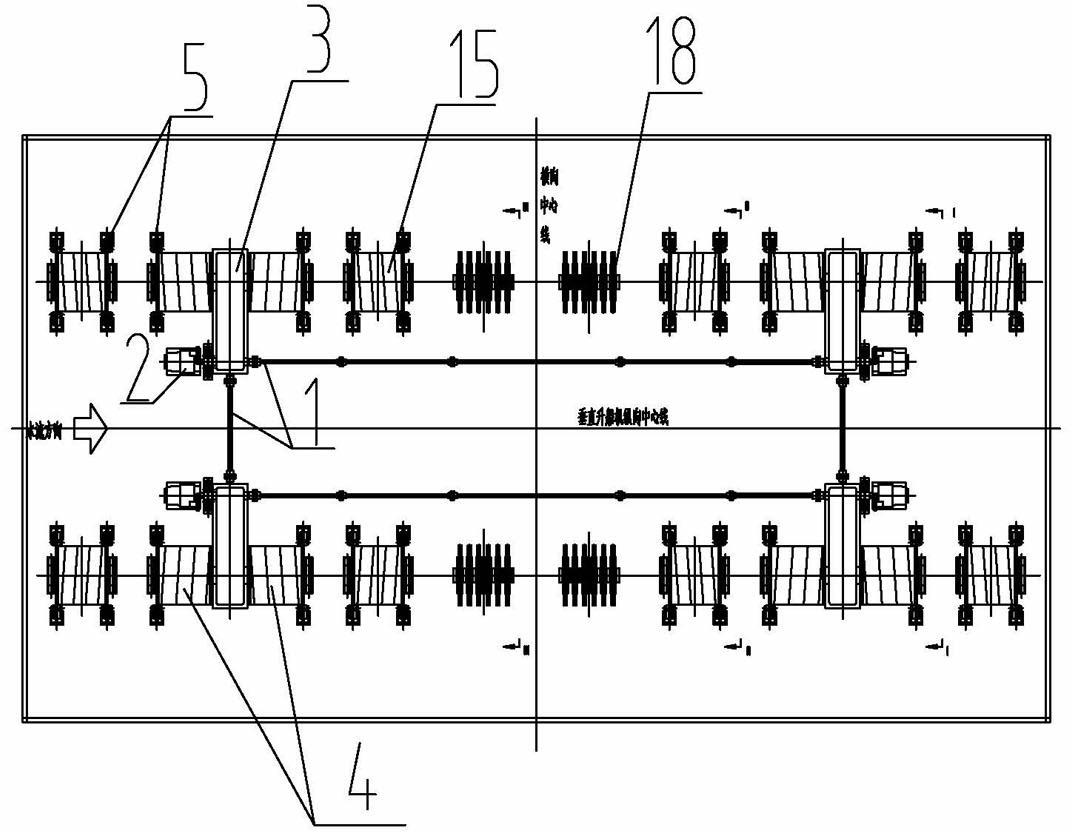

[0028] Such as figure 1 , image 3 As shown, the present embodiment is a full-balanced vertical ship lift adapted to the water entry of the ship-holding box. The lifting drive system of the ship-holding box 12 above the water surface and the lifting drive system of the ship-holding box entering and leaving the water are respectively fully balanced. The system's electric drive scheme and hydraulic control drive scheme.

[0029] This example includes the main hoisting equipment that is symmetrically installed on the dam body 16 on both sides of the elevator shaft 19: four main hoisting drums 4, eight controllable counterweight drums 15 and four pulley blocks 18 (see image 3 ), also includes the ship-holding compartment 12 that can move up and down along the elevator shaft. Both the main hoist drum 4 and the controllable balance weight drum 15 are equipped with brakes 5, the total braking torque is sufficient to reliably brake the maximum unbalanced load of the system after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com