Hollow guardrail plate

A guardrail, hollow technology, applied in layered products, buildings, metal layered products, etc., can solve the problems of small elastic modulus, poor impact energy absorption, and high cost of all-plastic materials, and achieve strong flexibility and cushioning capacity , prolong the contact time and reduce the impact peak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

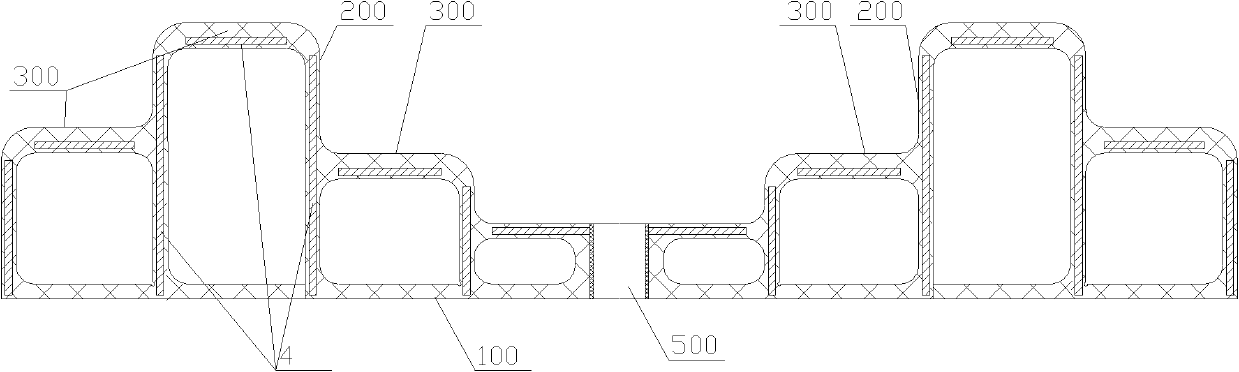

[0076] Embodiment 1, as figure 1 In the shown guardrail board, the beam plate 100 is a flat thermoplastic material plate, and a plurality of installation holes 500 are spaced apart on the central axis of the beam plate 100, and eight first rib plates 200 are arranged in parallel longitudinally along the beam plate 100, wherein Two are set on the edges of both sides of the beam slab 100, and the others are evenly distributed in the direction of the center of the beam slab 100. The width of the first rib 200, that is, the distance between the bottom end and the top end of the first rib 200, can be the same or different. , and the eight first ribs 200 are symmetrical with respect to the longitudinal center axis of the beam slab 100. In this embodiment, first ribs 200 of different widths are used. Among the four first ribs 200 on one side of the central axis of the beam slab 100 , the two first ribs 200 in the middle are wider than the width of the first ribs 200 on both sides. T...

Embodiment 2

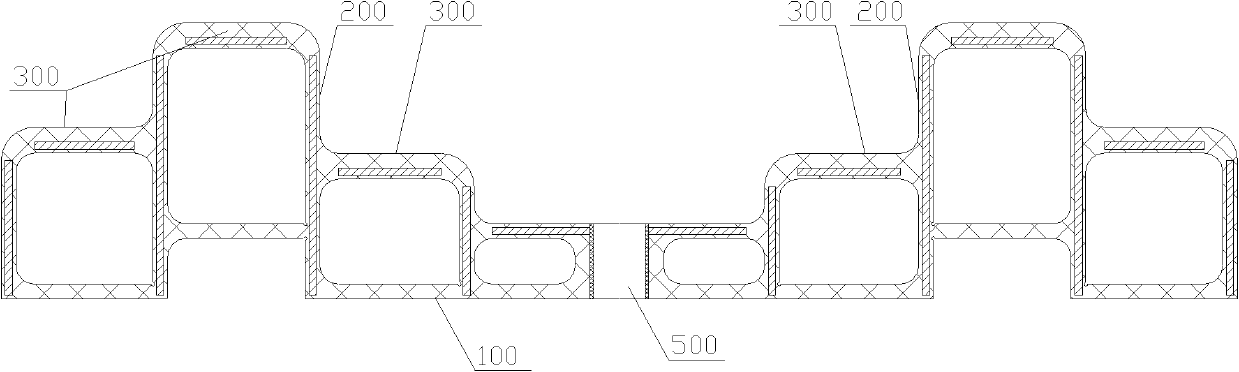

[0078] Embodiment 2, as figure 2 The shown guardrail board is an improvement made on the basis of Embodiment 1, wherein the beam board 100 is a special-shaped board obtained by bending a flat board, and two square ribs are formed along the longitudinal direction, among which there are four first rib boards 200 Located on the edge of the rib and forming an integral structure with the rib, two are located on the edge of the beam plate 100 . Since the first rib 200 is made of a thermoplastic composite board, the reinforcing frame in the first rib 200 on the rib of the beam plate 100 extends toward the side wall of the rib, and the rest of the structure is the same as that of Embodiment 1 and will not be repeated here.

Embodiment 3

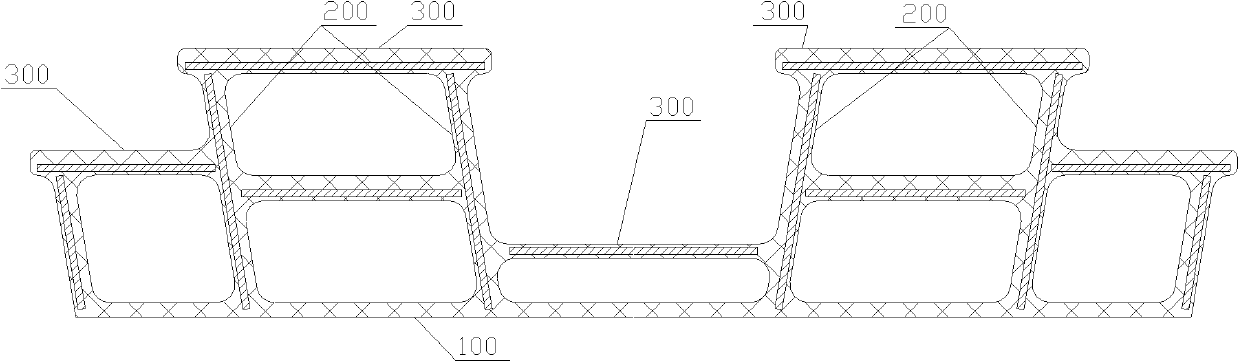

[0079] Embodiment 3, as image 3 The shown guardrail is an improvement on the basis of Embodiment 1. The beam plate 100 remains unchanged, and six first rib plates 200 are provided. The six first rib plates 200 are symmetrical about the central axis of the beam plate 100, and each side of the central axis Set three first ribs 200, the first ribs 200 on the same side are all inclined to the edge of the beam plate 100, the inclination angle is the same or different, the inclination angle of the first rib 200 is 70-85°, the second rib 300 In this embodiment, part adopts a two-layer structure, and the other part adopts a single-layer structure. That is, among the six first ribs 200, two layers of second ribs 300 are set between the second and third second ribs 300 from the edge, and between the fourth and fifth second ribs 300. A layer of second ribs 300 is arranged between the first ribs 200 . The second rib 300 disposed at the top of the first rib 200 extends toward the direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com