Cable-end sealing method for suspension cable of suspension bridge

A sling, end-sealing technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as poor sealing effect, easy damage, and errors in the processing of sealing rubber ring connecting cylinders, so as to avoid color inconsistency, inconsistency, etc. Easy to damage, to achieve self-adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The method for sealing the cable end of the suspension bridge sling of the present invention, the method comprises the following process steps:

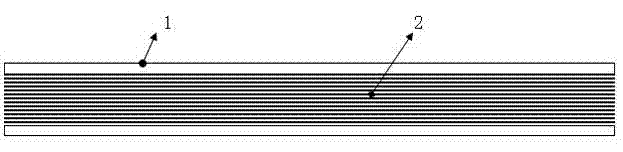

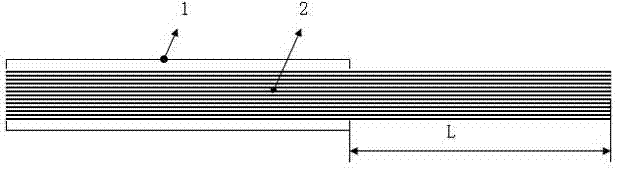

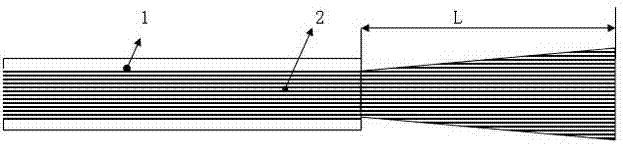

[0054] Put the end of the sling according to the anchor length L in the anchor 1 It is required to completely peel off a section of polyethylene sheath 1 to expose the steel wire bundle 2, such as Figure 6 . Then, in order to meet the dispersion requirements of the steel wire bundles, the polyethylene sheath is cut into two slits along the length direction to form two semicircular sheath sections 3 whose tails are connected, and the cut length is L 2 ,Such as Figure 7 , 8 . Then pass the steel wire bundle through the anchorage for splitting, and the splitting length is L. The cut polyethylene sheath can be partly separated during wire splitting to meet the purpose of steel wire splitting, such as Figure 9 . After the steel wires are separated, the steel wire bundles are installed in the anchorage 4, and then the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com