Plastic flat fiber extruding machine set

A plastic flat yarn and wire drawing technology, which is applied in stretch spinning, filament/thread forming, textiles and papermaking, etc., can solve the problems of difficult resin drawing processing and no processing and production equipment, so as to save raw materials, technology and Reasonable structure design, effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

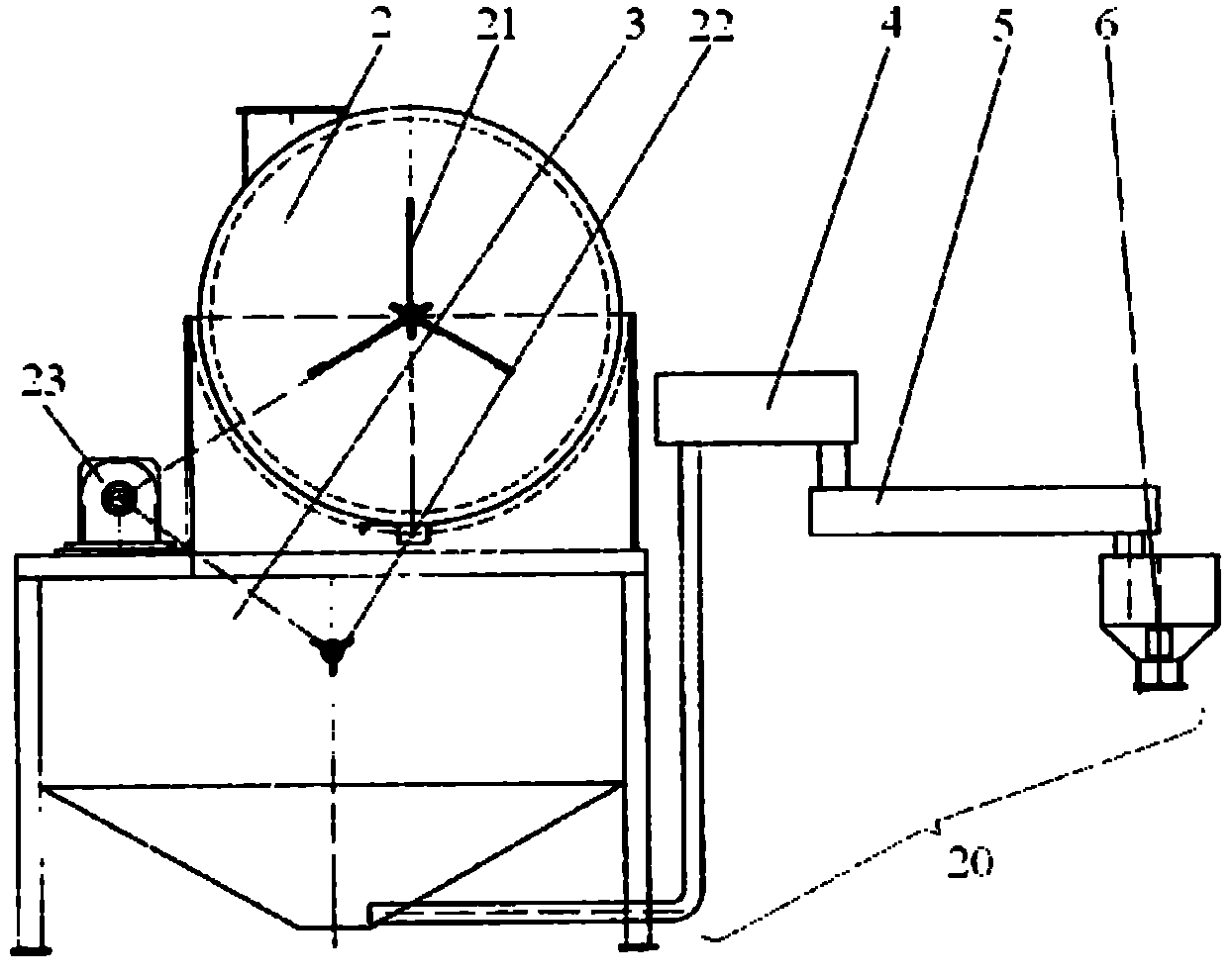

[0034] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

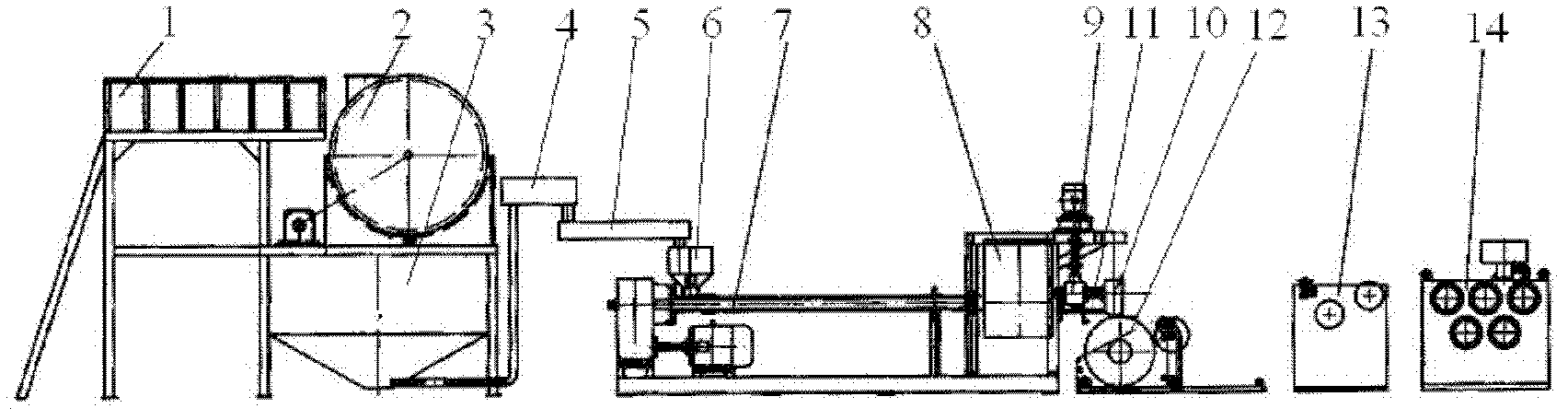

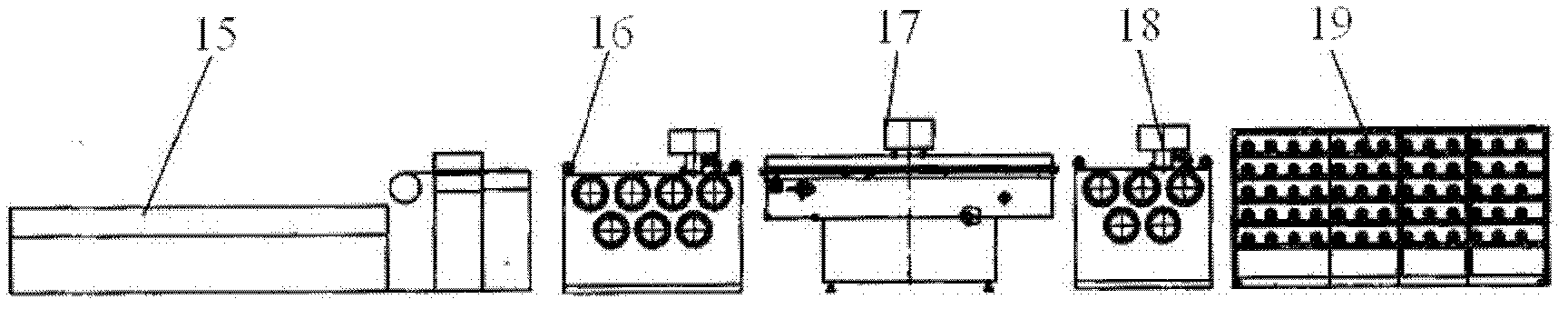

[0035] Such as figure 1 , figure 2 The structure of the present invention expressed is a plastic flat wire drawing unit, including a drying conveying device, an extruder 7, a filter 8, a metering pump 9, a die head 10, a traction device, a wire dividing device 13, and a stretching device 15. The wire collecting device 19 is distributed according to the technological process; the drying material tank 2 is set in the drying conveying device.

[0036] figure 1 The structure in is the first half of the plastic flat wire drawing unit, figure 2 The structure in is the second half of the plastic flat wire drawing unit, and the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com