Method for preparing Al-Ti-B intermediate alloy refining agent for aluminum

An intermediate alloy, al-ti-b technology, applied in the field of aluminum alloy refiner and its preparation, can solve the problems of slow reaction speed, high preparation temperature of oxide method, large amount of harmful gas emission of fluorine salt method, etc. Harmful gas reduction, good effect, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

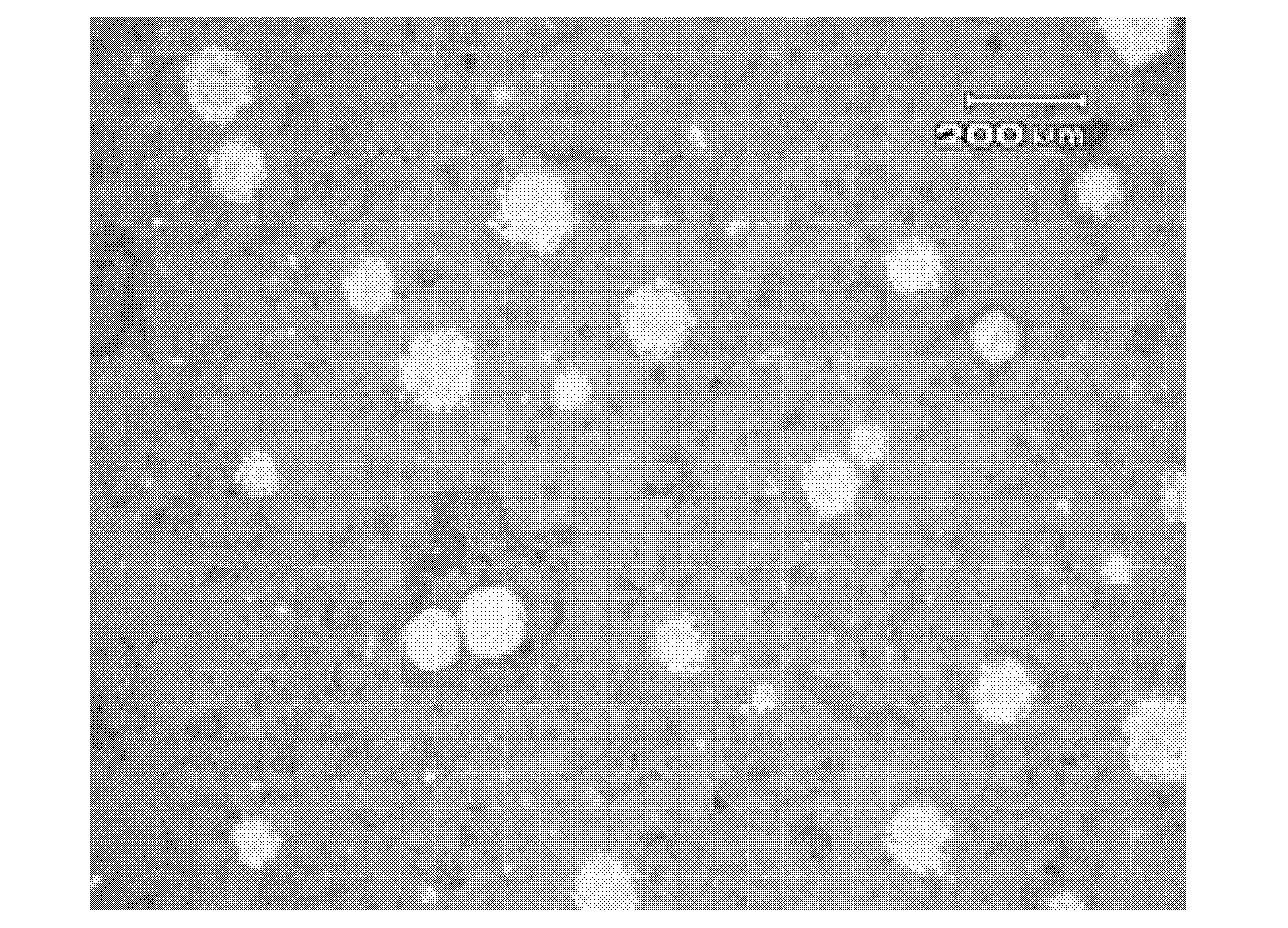

[0021] Specific embodiment 1: The preparation method of a kind of Al-Ti-B master alloy refiner for aluminum of the present embodiment is carried out according to the following steps: 1. Weigh 1% to 7% of pure Ti by mass percentage powder, 0.28% to 4.20% boric acid, 72% to 86% pure aluminum block and 1.71% to 17.1% potassium fluoroborate; then weigh 10% to 20% of the total mass of pure Ti powder, boric acid and potassium fluoroborate Potassium chlorate; 2. Add the pure Ti powder, boric acid, potassium fluoroborate and potassium chlorate weighed in step 1 into the powder mixer, and stir evenly at a speed of 100rpm to 300rpm to obtain a mixture; 3. The powder weighed in step 1 Put the pure aluminum block into the crucible, heat to 750°C-950°C to melt the pure aluminum block, then add the mixture obtained in step 2, and stir evenly at a speed of 200rpm-500rpm, and then heat it under the condition of 750°C-950°C Insulate for 15min to 50min to obtain the aluminum alloy melt; 4. Dega...

specific Embodiment approach 2

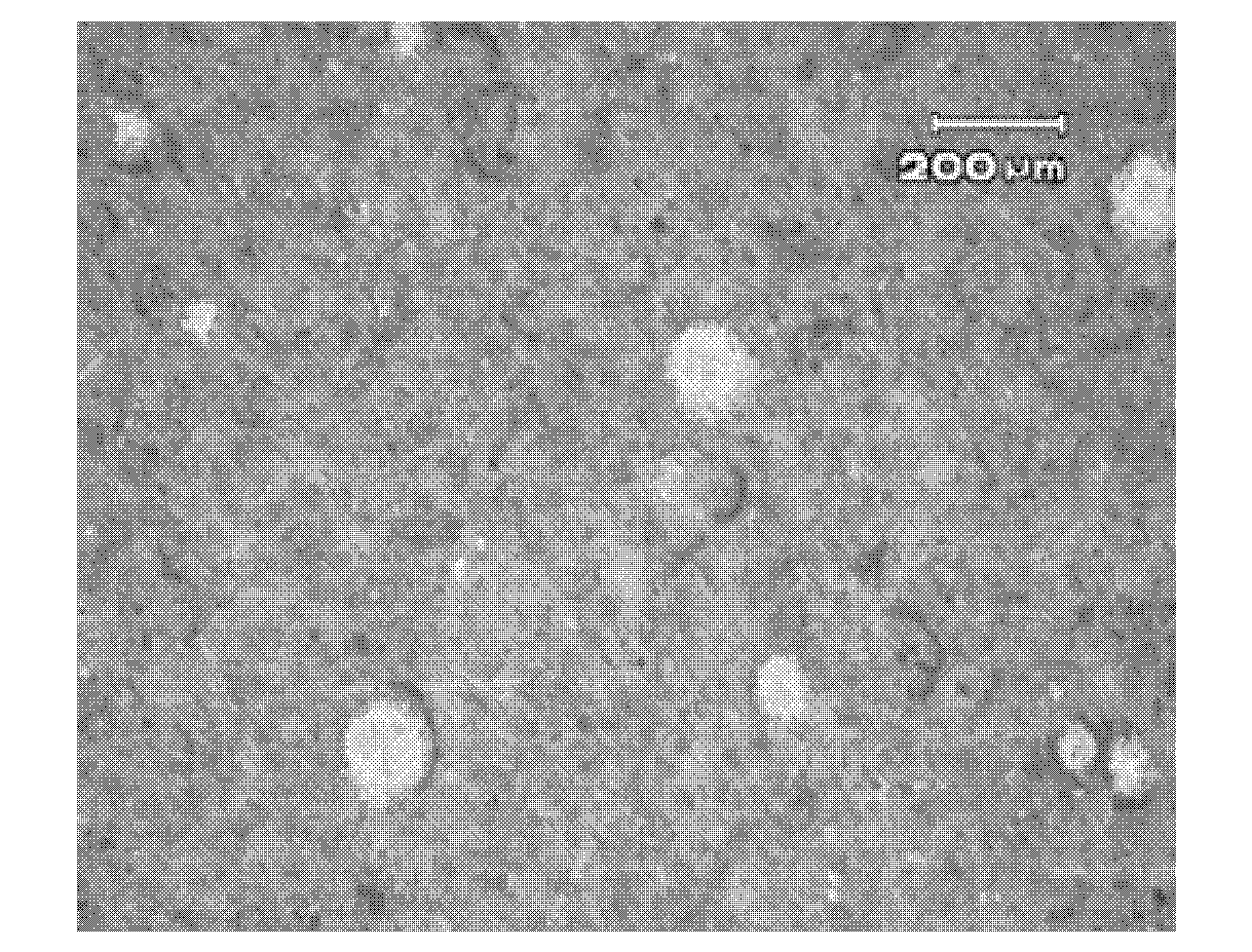

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 3% to 5% of pure Ti powder, 1% to 2% of boric acid, 78% to 82% pure aluminum block and 6%-12% potassium fluoroborate; then weigh 14%-16% potassium chlorate accounting for the total mass of pure Ti powder, boric acid and potassium fluoroborate. Others are the same as in the first embodiment.

specific Embodiment approach 3

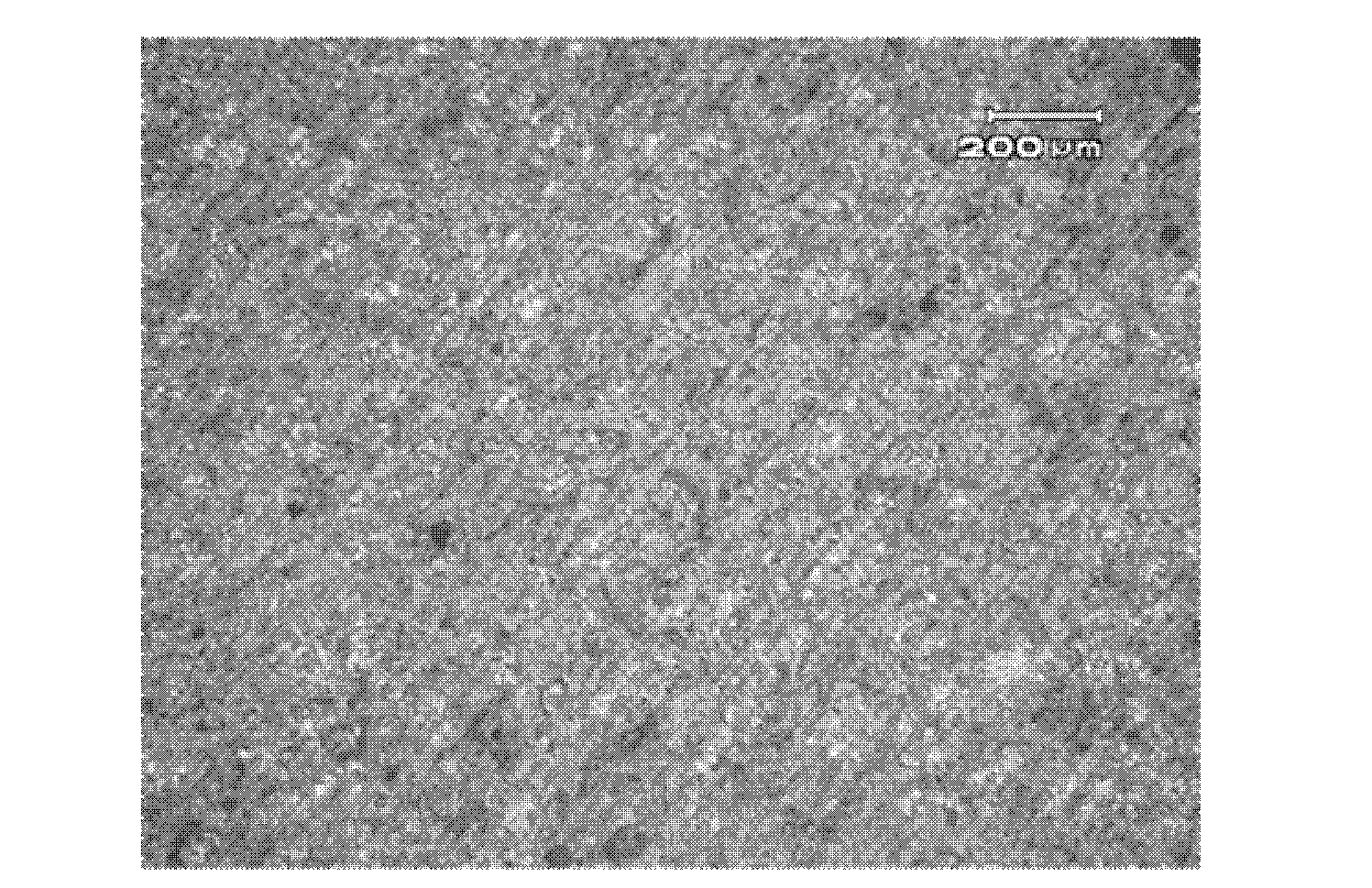

[0026] Specific embodiment three: the difference between this embodiment and specific embodiments one to two is: the degassing described in step four is to add a degassing agent with a graphite bell jar, stir at a speed of 60 ~ 120rpm for 2 ~ 5min, and then let it stand for 3 minutes ~8min for degassing. Others are the same as the specific embodiment 1 to 2.

[0027] The degassing agent in this embodiment is purchased from Zhongshan Huayu Nonferrous Metallurgical Materials Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com